Six sigma-in-measurement-systems-evaluating-the-hidden-factory (2)

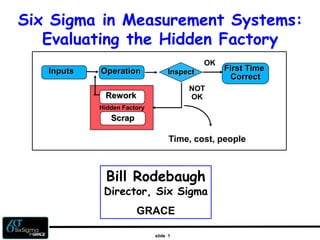

- 1. Six Sigma in Measurement Systems: Evaluating the Hidden Factory Inputs Operation Inspect First Time slide 1 Rework Hidden Factory Scrap NOT OK Correct OK Time, cost, people Bill Rodebaugh Director, Six Sigma GRACE

- 2. Objectives The Hidden Factory Concept What is a Hidden Factory? What is a Measurement System’s Role in the Hidden slide 2 Factory? Review Key Measurement System metrics including %GR&R and P/T ratio Case Study at W. R. GRACE Measurement Study Set-up and Minitab Analysis Linkage to Process Benefits of an Improved Measurement System How to Improve Measurement Systems in an Organization

- 3. The Hidden Factory -- Process/Production Inputs Operation Inspect First Time slide 3 Rework Hidden Factory Scrap NOT OK Correct OK Time, cost, people •What Comprises the Hidden Factory in a Process/Production Area? •Reprocessed and Scrap materials -- First time out of spec, not reworkable •Over-processed materials -- Run higher than target with higher than needed utilities or reagents •Over-analyzed materials -- High Capability, but multiple in-process samples are run, improper SPC leading to over-control

- 4. The Hidden Factory -- Measurement Systems slide 4 Re-test Hidden Factory Waste OK NOT OK Sample Lab Work Inputs Inspect Production Time, cost, people •What Comprises the Hidden Factory in a Laboratory Setting? •Incapable Measurement Systems -- purchased, but are unusable due to high repeatability variation and poor discrimination •Repetitive Analysis -- Test that runs with repeats to improve known variation or to unsuccessfully deal with overwhelming sampling issues •Laboratory “Noise” Issues -- Lab Tech to Lab Tech Variation, Shift to Shift Variation, Machine to Machine Variation, Lab to Lab Variation

- 5. The Hidden Factory Linkage Production Environments generally rely upon in-process sampling for adjustment As Processes attain Six Sigma performance they begin to rely less on sampling and more upon leveraging the few influential X variables The few influential X variables are determined largely through multi-vari studies and Design of Experimentation (DOE) Good multi-vari and DOE results are based upon acceptable measurement analysis slide 5

- 6. Objectives The Hidden Factory Concept What is a Hidden Factory? What is a Measurement System’s Role in the Hidden slide 6 Factory? Review Key Measurement System metrics including %GR&R and P/T ratio Case Study at W. R. GRACE Measurement Study Set-up and Minitab Analysis Linkage to Process Benefits of an Improved Measurement System How to Improve Measurement Systems in an Organization

- 7. Possible Sources of Process Variation Measurement Variation Variation due to gage 2 Pr Pr 2 Re Re We will look at “repeatability” and “reproducibility” as primary contributors to measurement error slide 7 Stability Linearity Long-term Process Variation Short-term Process Variation Variation w/i sample Actual Process Variation Repeatability Calibration Variation due to operators Observed Process Variation Measuremen t System 2 Actua l ocess 2 Observed ocess producibility 2 peatability 2 Measuremen t System

- 8. How Does Measurement Error Appear? slide 8 30 40 50 60 70 80 90 100 110 15 10 5 0 Observ ed Frequency LSL USL Actual process variation - No measurement error Observed process variation - With measurement error 30 40 50 60 70 80 90 100 110 15 10 5 0 Process Frequency LSL USL

- 9. Measurement System Terminology Discrimination - Smallest detectable increment between two measured values slide 9 Accuracy related terms True value - Theoretically correct value Bias - Difference between the average value of all measurements of a sample and the true value for that sample Precision related terms Repeatability - Variability inherent in the measurement system under constant conditions Reproducibility - Variability among measurements made under different conditions (e.g. different operators, measuring devices, etc.) Stability - distribution of measurements that remains constant and predictable over time for both the mean and standard deviation Linearity - A measure of any change in accuracy or precision over the range of instrument capability

- 10. Measurement Capability Index - P/T Precision to Tolerance Ratio . * MS / Addresses what percent of the tolerance is taken up by slide 10 measurement error Includes both repeatability and reproducibility Operator x Unit x Trial experiment Best case: 10% Acceptable: 30% Usually expressed as percent P T Tolerance 515 Note: 5.15 standard deviations accounts for 99% of Measurement System (MS) variation. The use of 5.15 is an industry standard.

- 11. Measurement Capability Index - % GR&R MS Addresses what percent of the Observed Process Variation is taken up by measurement error %R&R is the best estimate of the effect of measurement systems on the validity of process improvement studies (DOE) Includes both repeatability and reproducibility As a target, look for %R&R < 30% slide 11 Usually expressed as percent R R x 100 Observed Pr ocess Variation % &

- 12. Objectives The Hidden Factory Concept What is a Hidden Factory? What is a Measurement System’s Role in the Hidden slide 12 Factory? Review Key Measurement System metrics including %GR&R and P/T ratio Case Study at W. R. GRACE Measurement Study Set-up and Minitab Analysis Linkage to Process Benefits of an Improved Measurement System How to Improve Measurement Systems in an Organization

- 13. Case Study Background Internal Raw Material, A1, is necessary for Final Product production Expensive Raw Material to produce – produced at 4 locations Worldwide Cost savings can be derived directly from improved product quality, CpKs Internal specifications indirectly linked to financial targets for production costs are used to slide 13 calculate CpKs If CTQ1 of A1 is too low, then more A1 material is added to achieve overall quality – higher quality means less quantity is needed – this is the project objective High Impact Six Sigma project was chartered to improve an important quality variable, CTQ1 The measurement of CTQ1 was originally not questioned, but the team decided to study the effectiveness of this measurement The %GR&R, P/T ratio, and Bias were studied Each of the Worldwide locations were involved in the study Initial project improvements have somewhat equalized performance across sites. Small level improvements are masked by the measurement effectiveness of CTQ1

- 14. CTQ1 MSA Study Design (Crossed) slide 14 Site 1 Lab 6 analyses/site/sample 2 samples taken from each site 2*4 Samples should be representative Each site analyzes other site’s sample. Each plant does 48 analyses 6*8*4=196 analyses Site 1 Sample 1 Site 1 Sample 2 Op 1 Op 2 Op 3 T1 T2 Site 2 Lab Site 3 Lab Site 4 Lab Site 2 Sample 1…..

- 15. CTQ1 MSA Study Results (Minitab Output) UCL=52.45 UCL=851.5 slide 15 Gage name: Date of study: Reported by: Tolerance: Misc: Z-14 MSA JULY 2002 All Labs 110 Surface Area 120 100 80 60 40 20 100 CB1 CB2 CB3 LC1 LC2 LC3 V1 V2 V3 W1 W2 W3 50 900 CB1 CB2 CB3 LC1 LC2 LC3 V1 V2 V3 W1 W2 W3 0 850 800 750 Xbar Chart by Operator Sample Mean Mean=821.3 LCL=791.1 0 0 R Chart by Operator Sample Range R=16.05 LCL=0 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 890 840 790 890 840 790 900 850 800 Sample Operator Operator*Sample Interaction Average CB1 CB2 CB3 LC1 LC2 LC3 V1 V2 V3 W1 W2 CB1 CB2 CB3 LC1 LC2 LC3 V1 V2 V3 W1 W2 W3 740 Oper Response By Operator 740 Sample Response By Sample %Contribution %Study Var %Tolerance Gage R&R Repeat Reprod Part-to-Part 0 Components of Variation Percent

- 16. CTQ1 MSA Study Results (Minitab Session) Source DF SS MS F P Sample 7 14221 2031.62 5.0079 0.00010 Operator 11 53474 4861.27 11.9829 0.00000 Operator*Sample 77 31238 405.68 1.4907 0.03177 Repeatability 96 26125 272.14 slide 16 Total 191 125058 %Contribution Source VarComp (of VarComp) Total Gage R&R 617.39 90.11 Repeatability 272.14 39.72 Reproducibility 345.25 50.39 Operator 278.47 40.65 Operator*Sample 66.77 9.75 Part-To-Part 67.75 9.89 Sample, Operator, & Interaction are Significant

- 17. CTQ1 MSA Study Results slide 17 Site %GRR P/T Ratio R-bar Equal Variances within Groups Mean Differences (Tukey Comp.) All 94.3 (78.6 – 100)* 116 16.05 No (0.004) Only 1,2 No Diff. Site 1 38.9 (30.0 – 47.6) 29 7.22 Yes (0.739) All Pairs No Diff. Site 2 91.0 (70.7 – 100) 96 17.92 Yes (0.735) Only 1,2 Diff. Site 3 80.0 (60.8 – 94.8) 79 20.37 Yes (0.158) All Pairs No Diff. Site 4 98.0 (64.8 – 100) 120 18.67 Yes (0.346) Only 2,3 No Diff. *Conf Int not calculated with Minitab, Based upon R&R Std Dev

- 18. CTQ1 MSA Study Results (Minitab Output) Dotplot of All Samples over All Sites slide 18 WO SA VF SA LC SA CB SA 890 840 790 740 C17 C16 Dotplots of C16 by C17 (group means are indicated by lines) Site 1 Site 2 Site 3 Site 4

- 19. CTQ1 MSA Study Results (Minitab Session) slide 19 Analysis of Variance for Site Source DF SS MS F P Site 3 37514 12505 26.86 0.000 Error 188 87518 466 Total 191 125032 Individual 95% CIs For Mean Based on Pooled StDev Level N Mean StDev -+---------+---------+---------+----- Site 1 48 824.57 15.38 (---*---) Site 2 48 819.42 22.11 (---*---) Site 3 48 800.98 20.75 (---*---) Site 4 48 840.13 26.58 (---*---) -+---------+---------+---------+----- Pooled StDev = 21.58 795 810 825 840 Site and Operator are closely related

- 20. 790 60 40 20 CTQ1 MSA Study Results (Minitab Output) X-bar R of All Samples for All Sites 100 CB1 CB2 CB3 LC1 LC2 LC3 V1 V2 V3 W1 W2 W3 50 900 CB1 CB2 CB3 LC1 LC2 LC3 V1 V2 V3 W1 W2 W3 slide 20 0 850 800 750 Xbar Chart by Operator Sample Mean UCL=52.45 UCL=851.5 Mean=821.3 LCL=791.1 0 0 R Chart by Operator Sample Range R=16.05 LCL=0 1 2 740 Sample 890 Discrimination Index 840 is “0”, however can 790 probably see differences of 5 900 850 1 800 Sample Operator*Average CB1 CB2 CB3 740 Oper Gage R&R Repeat Reprod Part-to-Part 0 Percent Most of the samples are seen as “noise”

- 21. 50 CTQ1 MSA Study Results (Minitab Output) 70 W1 W2 W3 60 50 40 30 20 10 900 W1 W2 W3 •Mean differences are seen in X-bar area •Most of the samples are seen as “noise” slide 21 0 850 800 Xbar Chart by WO OP Sample Mean UCL=60.99 UCL=875.2 Mean=840.1 LCL=805.0 0 0 R Chart by WO OP Sample Range R=18.67 LCL=0 Gage R&R Repeat Reprod Part-to-Part 0 Percent X-bar R of All Samples for Site 4

- 22. 810 CTQ1 MSA Study Results – Process Linkage Site 2 Example 860 LC1 LC2 LC3 2 6662 2 22 2 slide 22 0 850 840 830 820 810 800 790 780 Xbar Chart by LC OP Sample Mean UCL=853.1 Mean=819.4 LCL=785.7 0 0 Sample R=17.92 LCL=0 LC OP*Sample 850 840 Average 830 820 810 800 MSA Study Results with Mean = 819.4 1 2 3 790 Sample LC1 760 LC OP 1000 900 800 700 Individual Value 1 1 6 1 6 1 4 222 4 6 1 1 2 1 5 1 1 6 1 1 66 222 2 55 Subgroup 0 100 200 300 400 UCL=899.2 Mean=832.5 LCL=765.8 150 100 50 Moving Range 1 1 1 1 11 1 1 1 1 1 1 1 UCL=81.95 I and MR Chart for TSA (t) 2002 Historical Process Results with Mean = 832.5 Selected Samples are Representative

- 23. CTQ1 MSA Study Results 810 – Process Linkage Site 2 Example 2 6662 2 22 UCL=58.54 UCL=853.1 2 66 222 slide 23 50 1000 1 1 1 1 1 1 1 1 100 LC1 LC2 LC3 900 800 50 700 6 6 4 222 4 6 1 2 5 6 1 1 860 LC1 LC2 LC3 0 850 840 830 820 810 800 790 780 Xbar Chart by LC OP Individual Value Sample Mean Mean=819.4 LCL=785.7 0 0 R Chart by LC OP Sample Range R=17.92 LCL=0 1 2 3 4 5 6 7 8 UCL=899.2 MSA Study Results with Range = 17.92, Calc for Subgroup UCL=81.95 1 2 3 4 5 6 7 8 55 860 810 850 840 830 820 810 800 790 Sample LC OP LC OP*Sample Interaction 2 Average LC1 LC2 LC3 LC1 LC2 LC3 760 LC OP By LC OP 760 Sample %Tolerance Gage R&R Repeat Reprod Part-to-Part 0 Percent 1 Subgroup 0 100 200 300 400 Mean=832.5 LCL=765.8 150 100 50 0 Moving Range 1 22 1 2 222 2 1 1 11 1 1 1 1 1 2 2 1 2 2 R=25.08 LCL=0 I and MR Chart for TSA (t) 2002 Historical Process Results with Range = 25.08 Calc for pt to pt When comparing the MSA with process operation, a large percentage of pt-to-pt variation is MS error (70%) --- a back check of proper test sample selection

- 24. CTQ1 MSA Study Results – Process Linkage Site 2 Example Key issue for Process Improvement Efforts is “When will we see change?” Initial Improvements to A1 process were made Control Plan Improvements to A1 process were initiated Site 2 Baseline Values were higher than other sites Small step changes in mean and reduction in variation will achieve goal How can Site 2 see small, real change with a Measurement System with Use Power and Sample Size Calculator with and without impact of MS variation. Lack of clarity in process improvement work, results in missed opportunity for improvement and continued use of non-optimal parameters slide 24 70+% GR&R?

- 25. CTQ1 MSA Study Results – Process Linkage Site 2 Example Simulated Reduction of Pt to Pt variation by 70% decreases time to observe savings by over 9X. slide 25 2-Sample t Test Alpha = 0.05 Sigma = 22.23 Sample Target Actual Difference Size Power Power 2 2117 0.9000 0.9000 4 530 0.9000 0.9002 6 236 0.9000 0.9002 8 133 0.9000 0.9001 10 86 0.9000 0.9020 12 60 0.9000 0.9023 14 44 0.9000 0.9007 16 34 0.9000 0.9018 18 27 0.9000 0.9017 20 22 0.9000 0.9016 2-Sample t Test Alpha = 0.05 Sigma = 6.67 Sample Target Actual Difference Size Power Power 2 192 0.9000 0.9011 4 49 0.9000 0.9036 6 22 0.9000 0.9015 8 13 0.9000 0.9074 10 9 0.9000 0.9188 12 7 0.9000 0.9361 14 5 0.9000 0.9156 16 4 0.9000 0.9091 18 4 0.9000 0.9555 20 3 0.9000 0.9095

- 26. CTQ1 MSA Study Results – Process Linkage Site 2 Example Benefits of An Improved MS Realized Savings for a Process Improvement Effort For A1, an increase of 1 number of CTQ1 is approximately $1 per ton Change of 10 numbers, 1000 Tons produced in 1 month (832 842) $1 * 10 * 1000 = $10,000 More trust in all laboratory numbers for CTQ1 Ability to make process changes earlier with R-bar at 6.67 Previously, it would be pointless to make any process changes within the 22 point range. Would you really see the change? As the Six Sigma team pushes the CTQ1 value higher, DOEs and other slide 26 tools will have greater benefit

- 27. Objectives The Hidden Factory Concept What is a Hidden Factory? What is a Measurement System’s Role in the Hidden slide 27 Factory? Review Key Measurement System metrics including %GR&R and P/T ratio Case Study at W. R. GRACE Measurement Study Set-up and Minitab Analysis Linkage to Process Benefits of an Improved Measurement System How to Improve Measurement Systems in an Organization

- 28. Measurement Improvement in the Organization Initial efforts for MS improvement are driven on a BB/GB project basis Six Sigma Black Belts and Green Belts Perform MSAs during Project Work Lab Managers and Technicians are Part of Six Sigma Teams Measurement Systems are Improved as Six Sigma Projects are Completed Intermediate efforts have general Operations training for lab personnel, mostly laboratory management Lab efficiency and machine set-up projects are started The %GR&R concept has not reached the technician level Current efforts enhance technician level knowledge and dramatically increase the number of MS projects MS Task Force initiated (3 BBs lead effort) Develop Six Sigma Analytical GB training All MS projects are chartered and reviewed; All students have a project Division-wide database of all MS results is implemented slide 28

- 29. Measurement Improvement in the Organization Develop common methodology for Analytical GB training Six Sigma Step Action Typical Six Sigma Tools Used Define Target measurement slide 29 system for study Identify KPOVs Project Charter Measure Identify KPIVs Evaluate KPOV performance “Soft” tools: Process Map, Cause & Effect Matrix, FMEA “Stat” tools: Minitab Graphics, SPC, Capability Analysis Analyze Measurement System Analysis Gage R&R, ANOVA, Variance Components, Regression, Graphical Interpretation Improve Reduce Reproducibility Reduce Repeatability Reduce Operator or Instrument Bias “Soft” tools: Fishbone Diagram, Focused FMEA “Stat” tools: D-Study, t-Tests and Regression, Design of Experiments Control Final Report Control Plan for KPIVs SPC, Reaction Plans, Control Plans, ISO synergy, Mistake Proofing

- 30. Final Thoughts The Hidden Factory is explored throughout all Six Sigma programs One area of the Hidden Factory in Production Environments is slide 30 Measurement Systems Simply utilizing Operations Black Belts and Green Belts to improve Measurement Systems on a project by project basis is not the long term answer The GRACE Six Sigma organization is driving Measurement System Improvement through: Tailored training to Analytical Resources Similar Six Sigma review and project protocol Communication to the entire organization regarding Measurement System performance As in the case study, attaching business/cost implications to poorly performing measurement systems