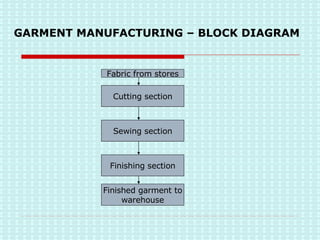

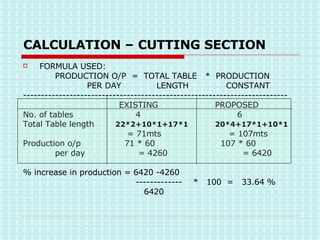

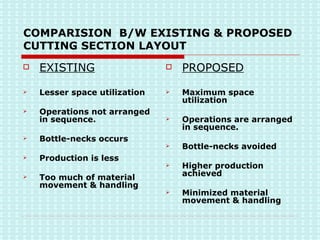

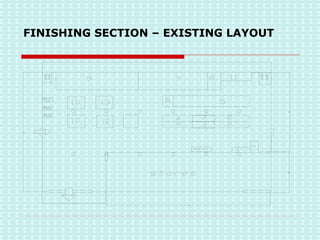

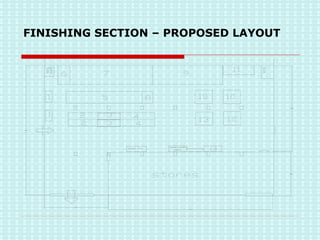

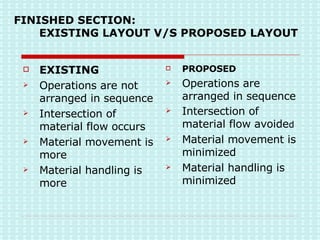

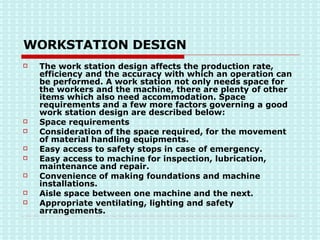

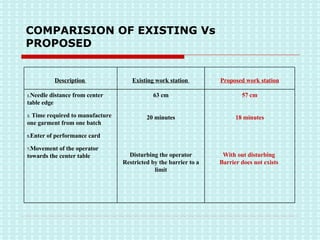

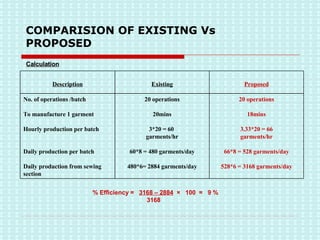

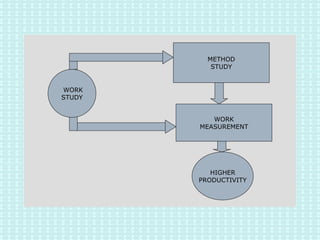

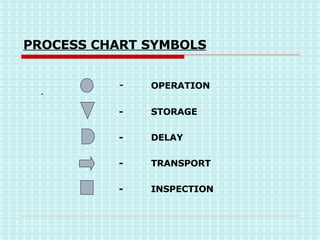

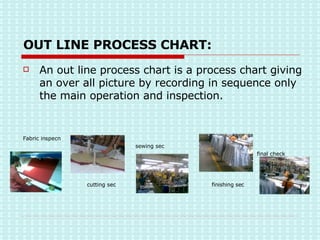

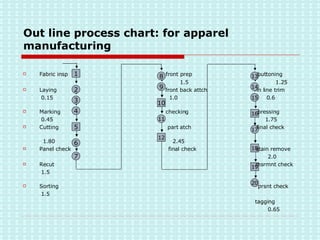

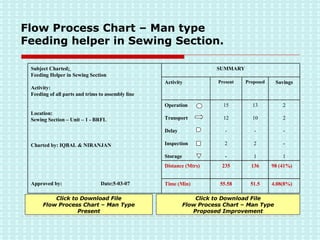

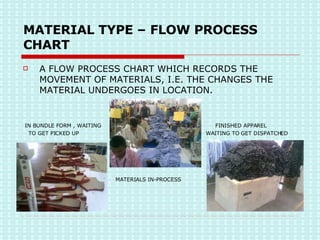

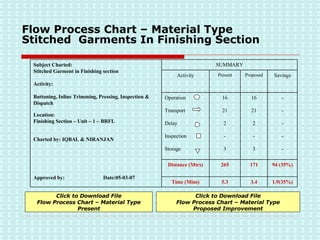

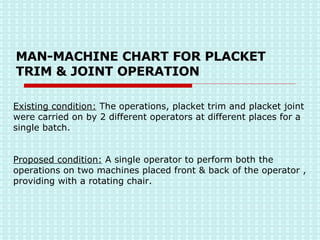

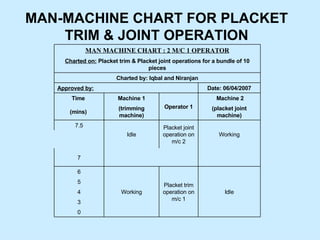

The document discusses the application of work study concepts in apparel manufacturing at Bombay Rayon Fashions Limited. It aims to optimize workplace utilization and productivity through analyzing existing plant layouts and workflows using process charts. Specific areas covered include redesigning the cutting, sewing and finishing sections layouts which improved space utilization and increased production output. Workstation designs and implementation of work study charts helped enhance efficiency.