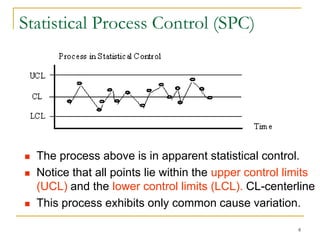

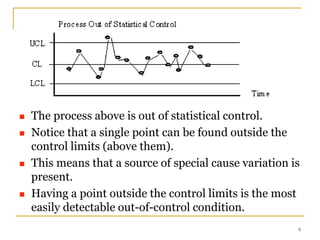

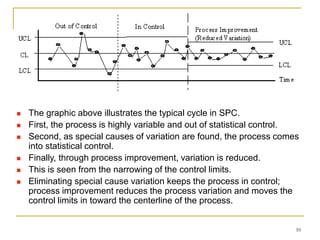

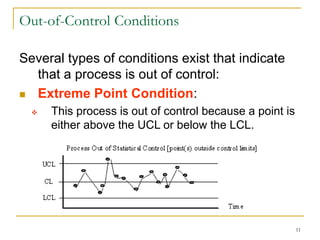

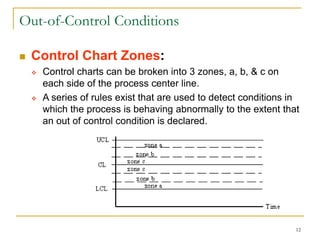

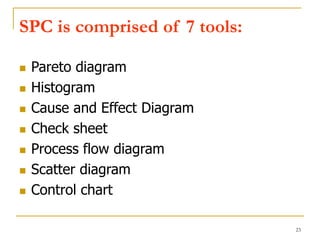

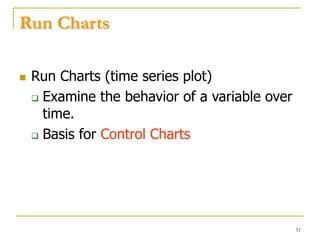

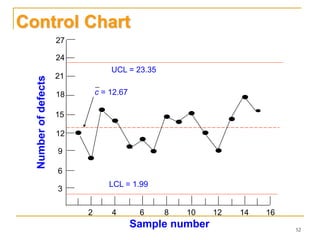

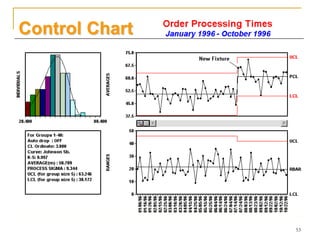

Statistical process control (SPC) uses statistical techniques to measure and analyze variation in processes, monitor product quality, and maintain processes within specified limits. A primary SPC tool is the control chart, which graphically displays descriptive statistics over time and detects unusual variation that could indicate a process problem. Control charts provide surveillance, signal when issues occur, and help reduce variation and improve process quality.