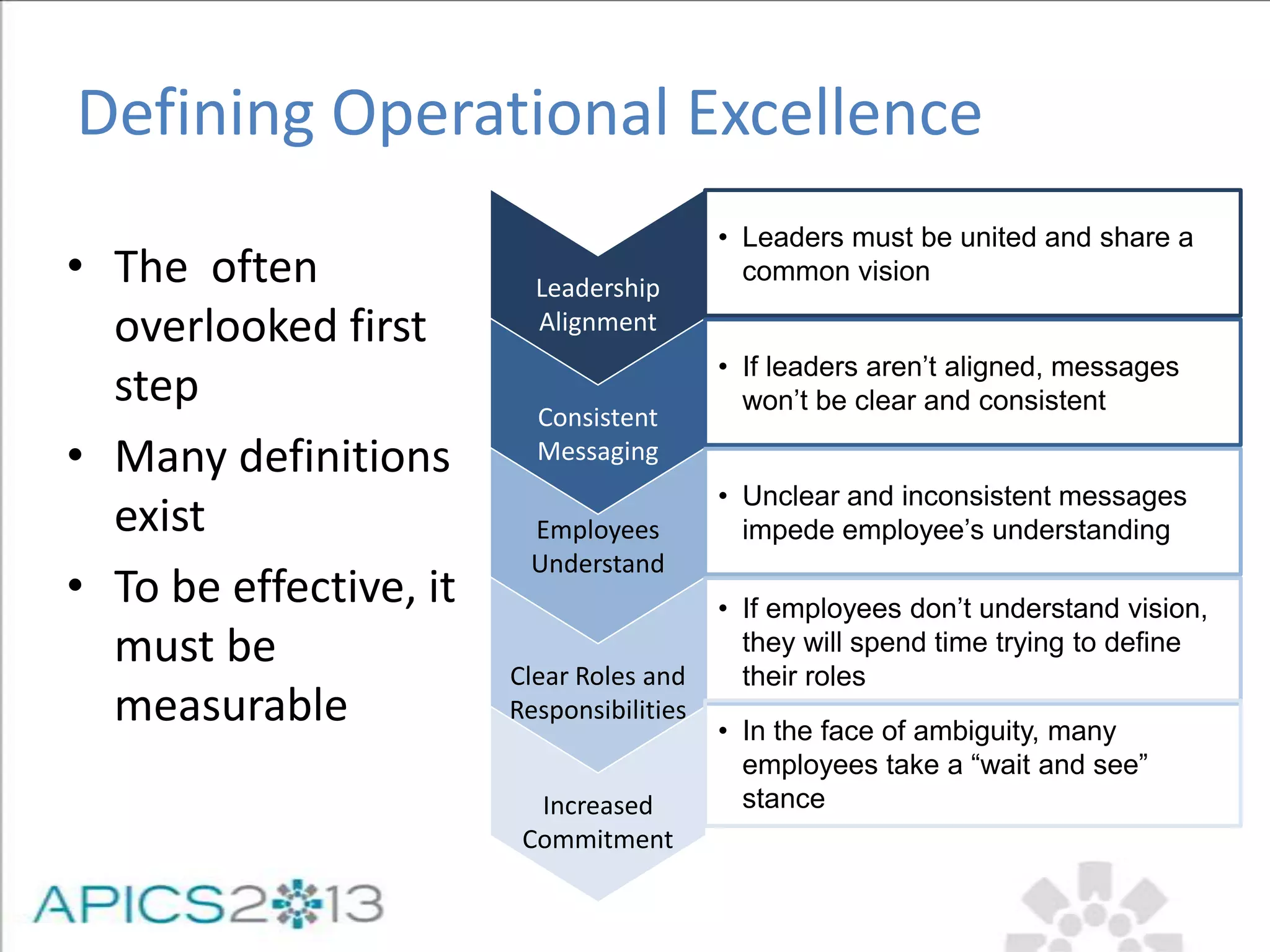

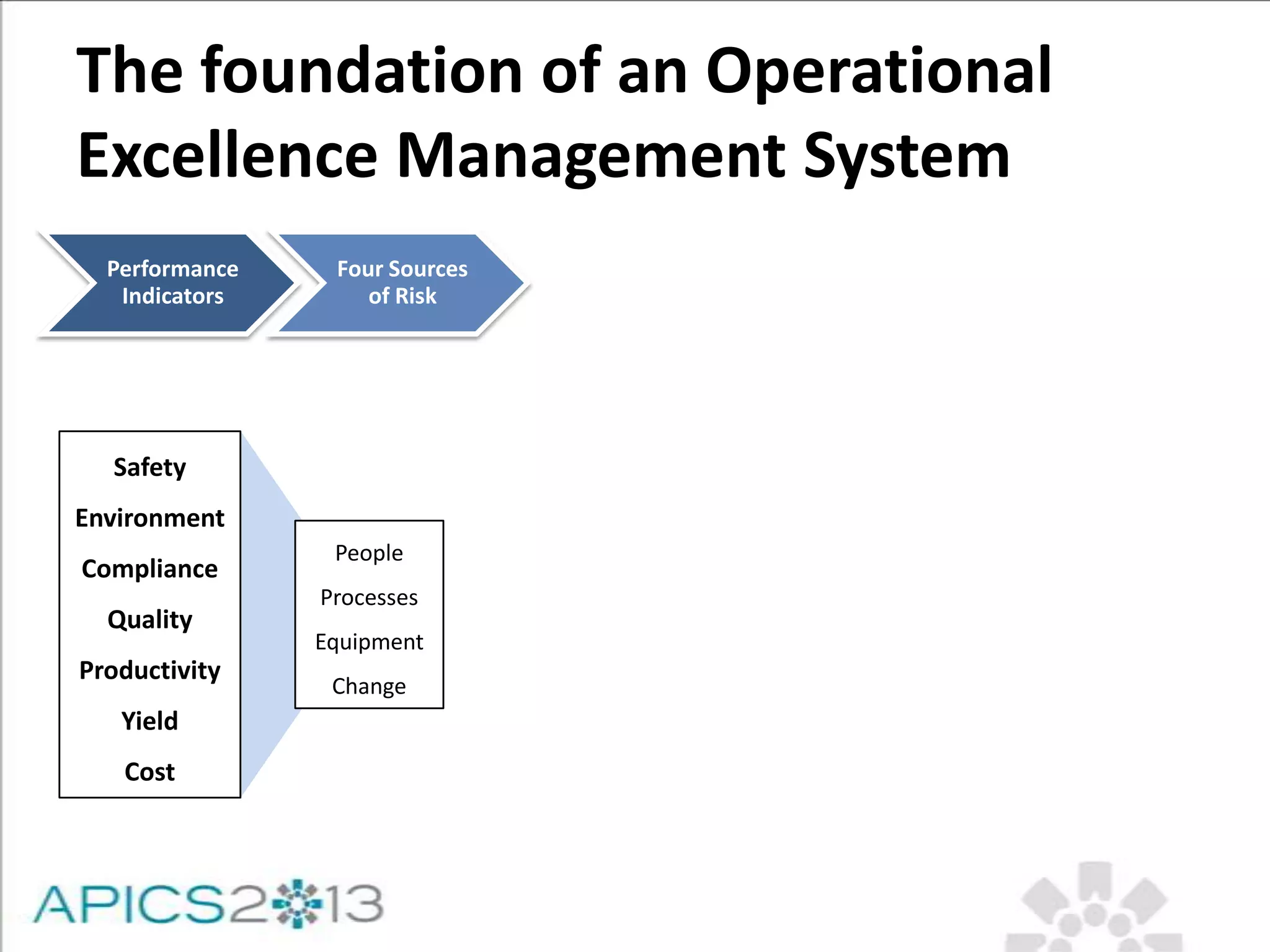

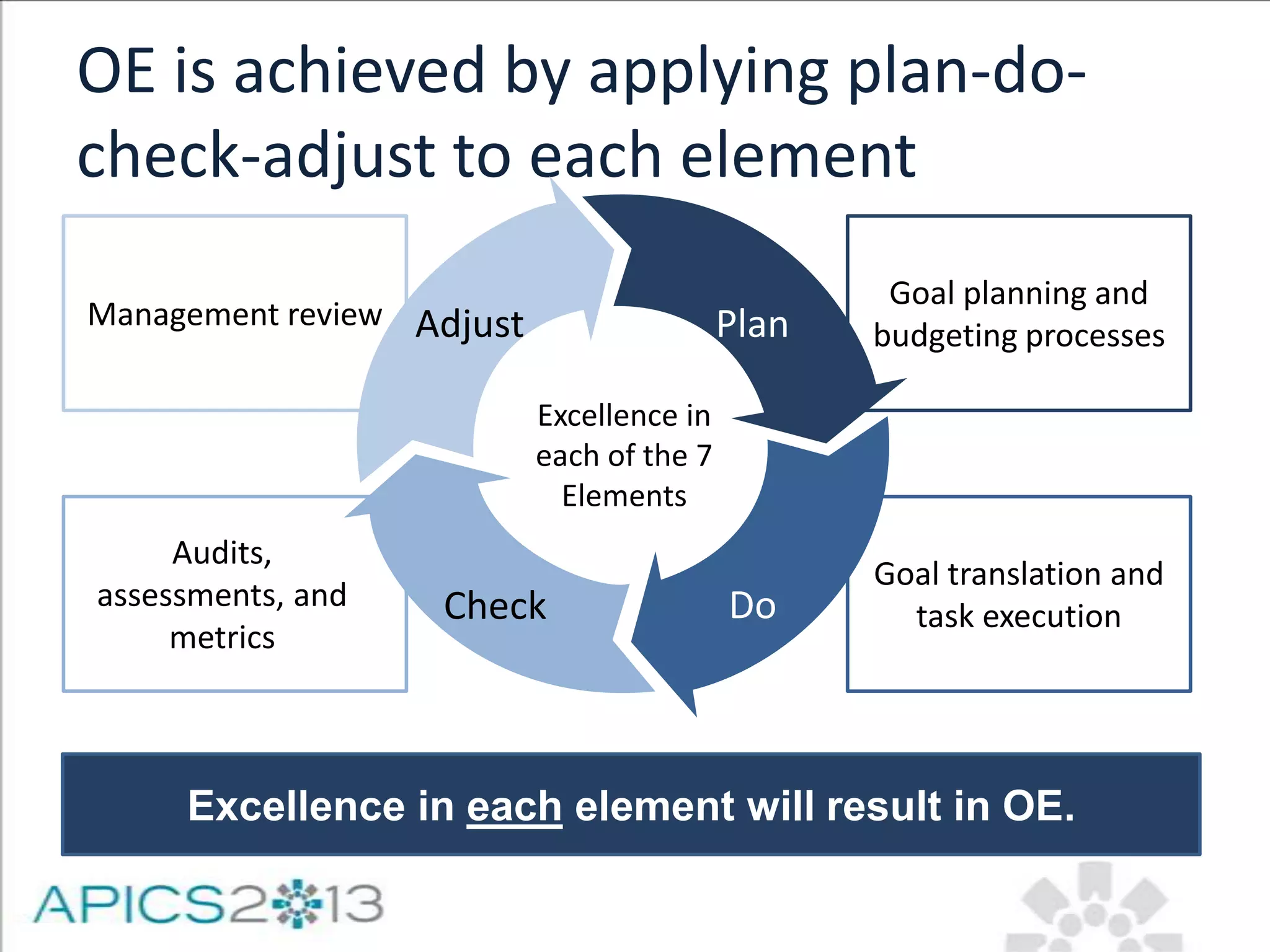

The document outlines a new approach to operational excellence (OE) that addresses the complexity of modern business environments, emphasizing the need for a measurable definition of OE and effective leadership alignment. It introduces an Operational Excellence Management System (OEMS) that focuses on understanding and managing sources of risk to enhance performance and combat the 'vicious complexity cycle'. Implementing this system involves applying a structured plan-do-check-adjust methodology across seven key elements, prioritizing leadership commitment and employee accountability.