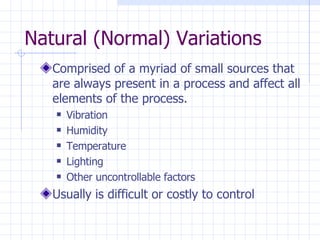

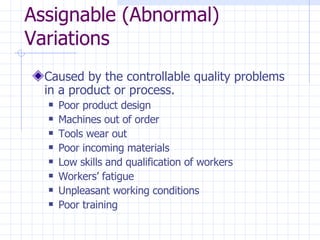

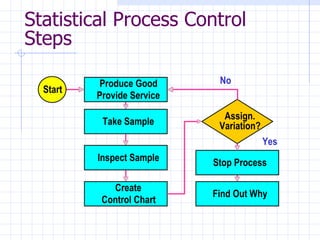

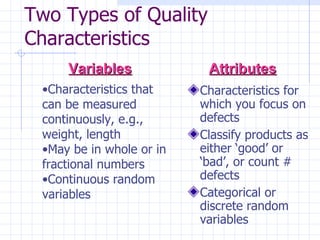

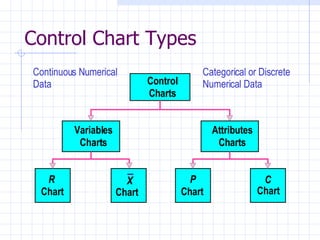

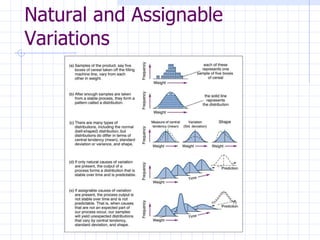

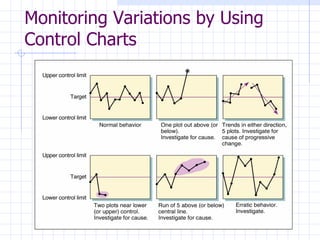

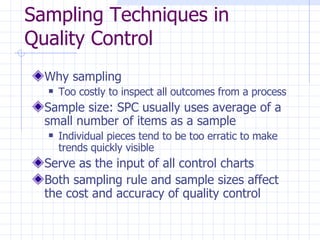

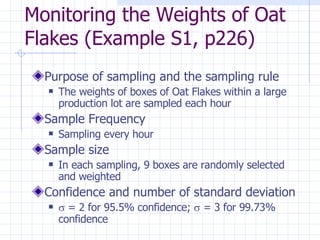

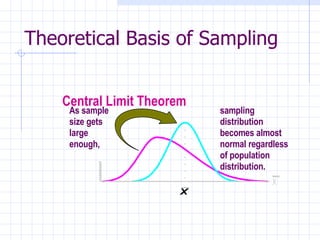

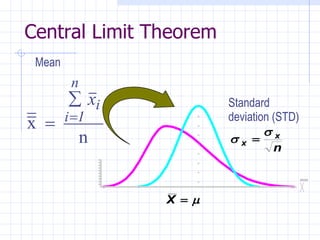

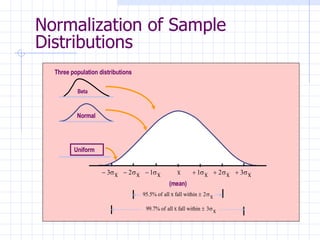

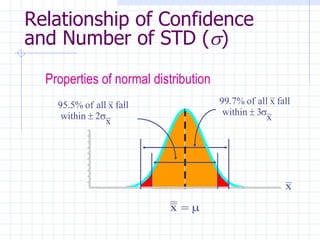

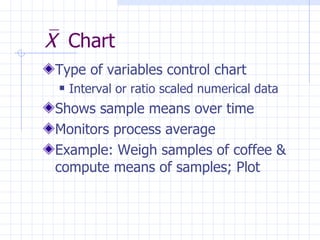

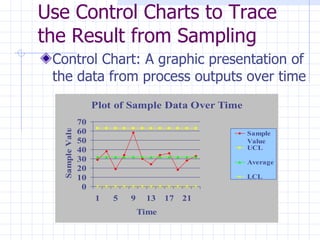

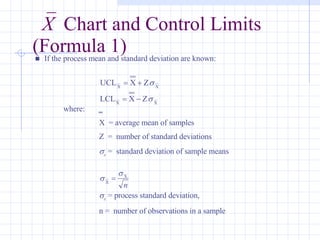

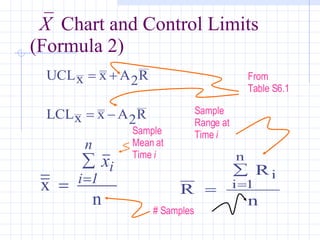

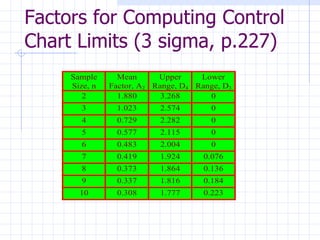

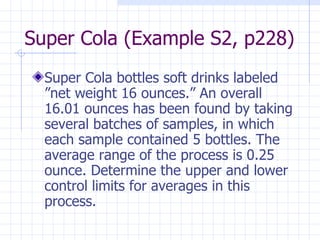

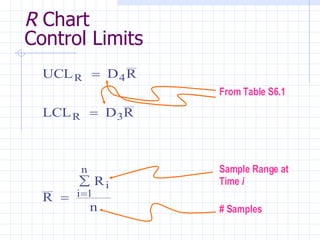

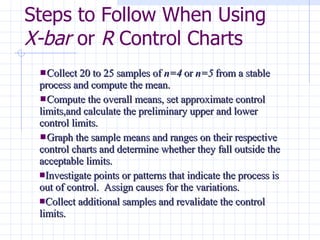

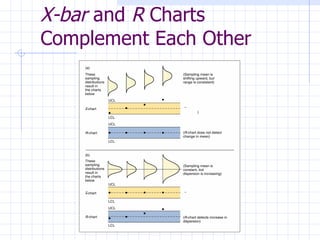

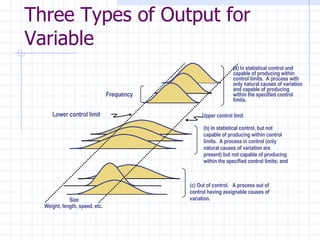

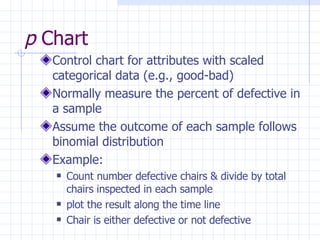

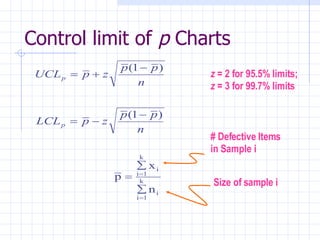

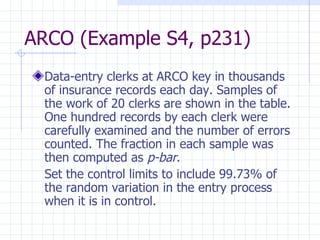

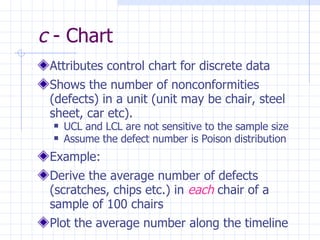

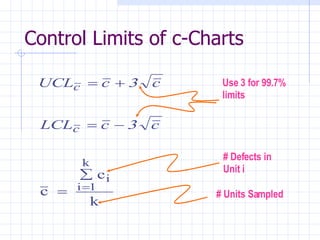

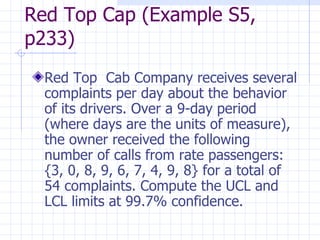

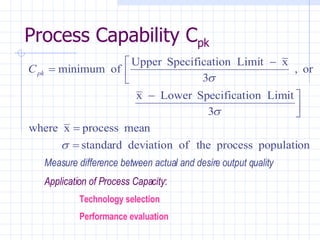

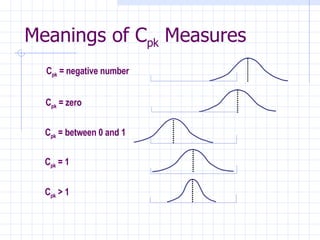

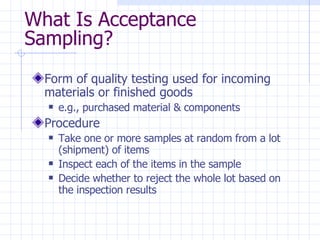

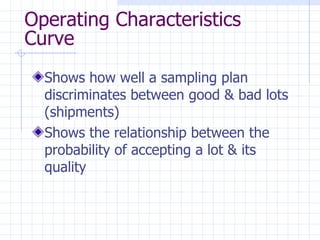

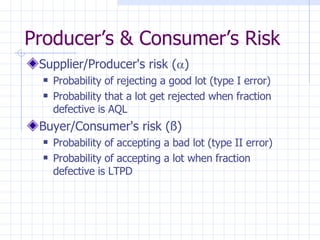

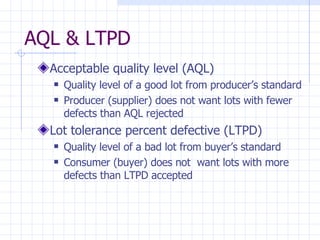

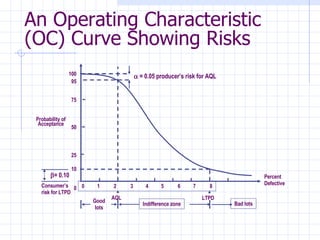

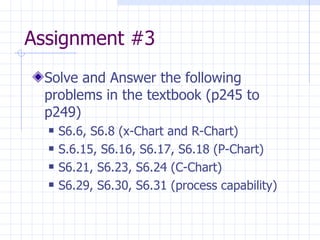

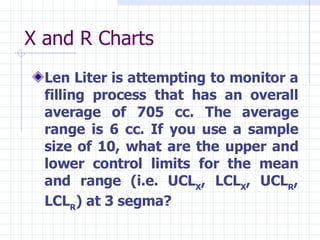

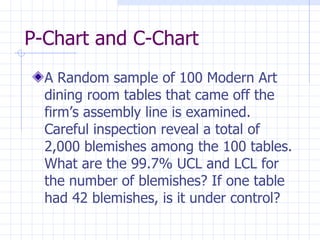

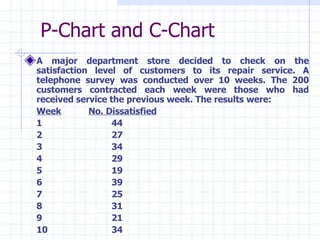

This document discusses statistical process control (SPC) techniques for quality management, including control charts for variables and attributes, sampling methods, process capability analysis, and acceptance sampling. It outlines how to select appropriate control charts, set control limits, identify assignable and natural causes of variation, and use control charts to monitor processes over time for process improvement.