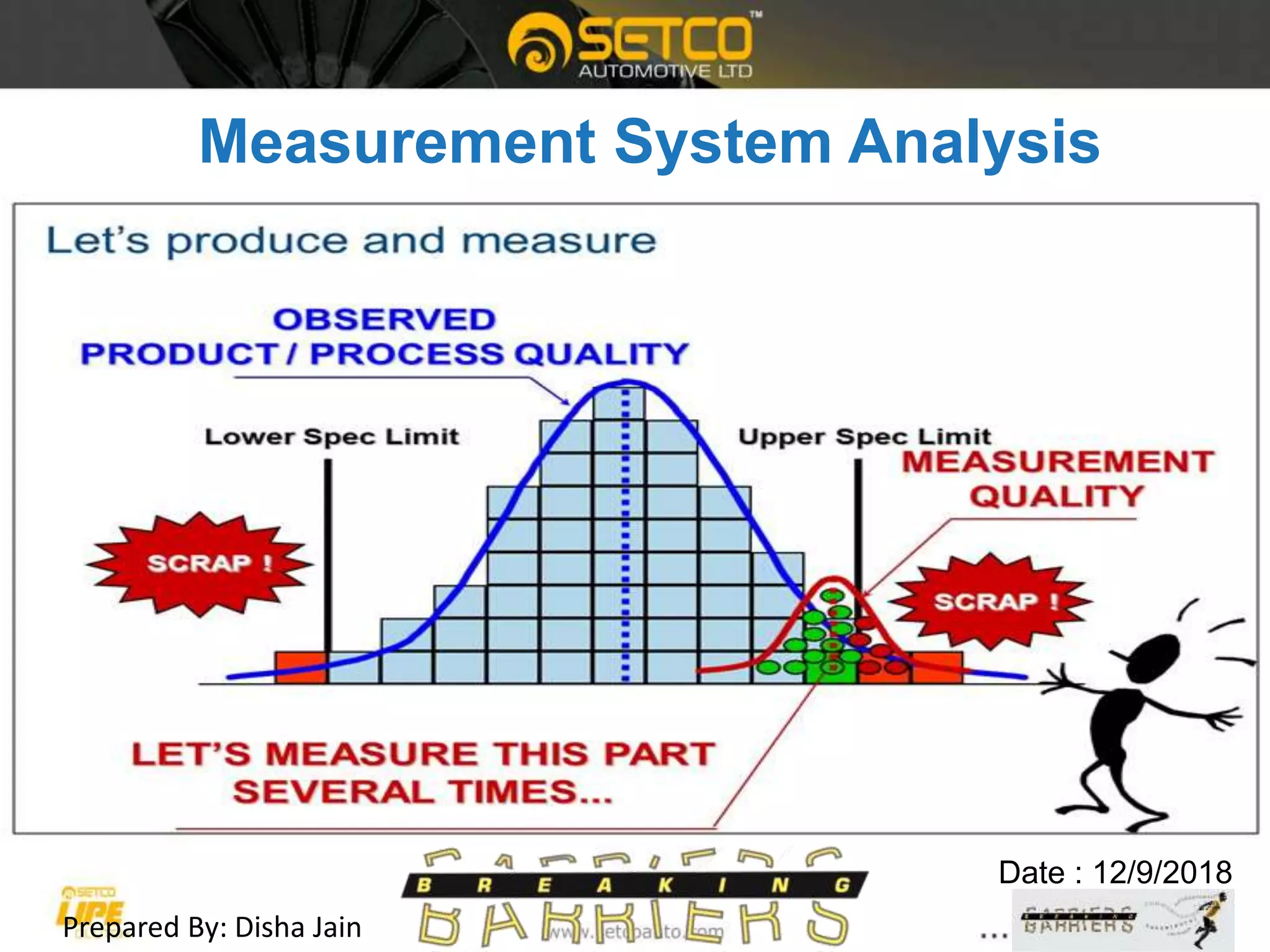

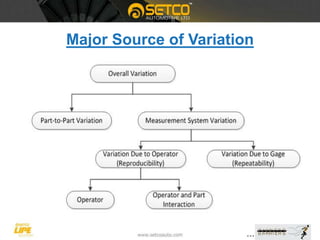

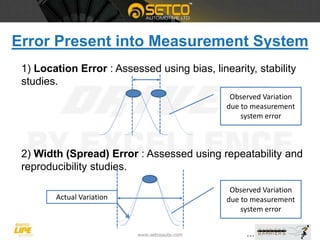

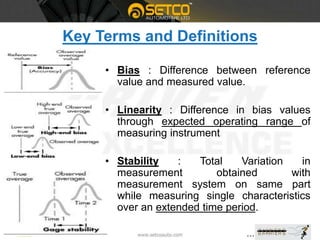

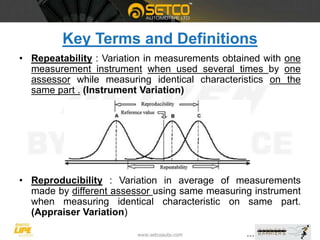

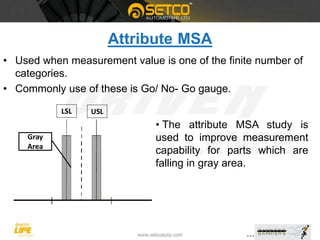

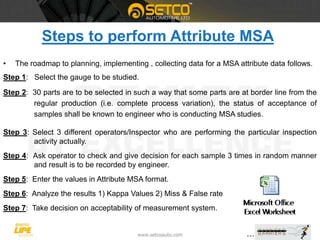

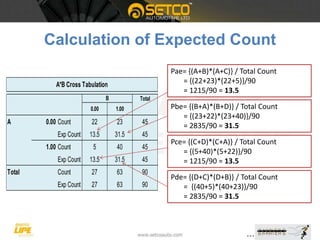

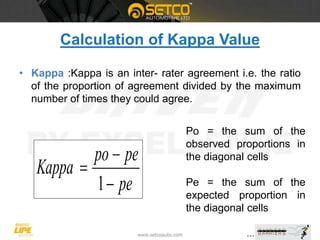

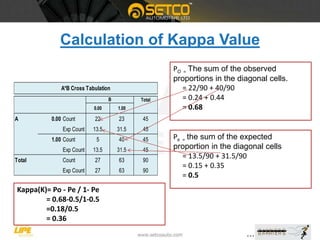

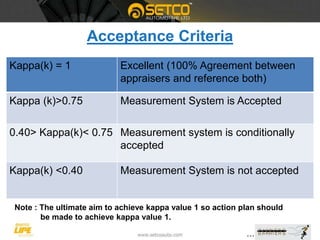

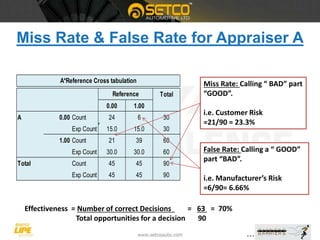

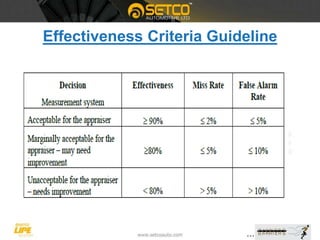

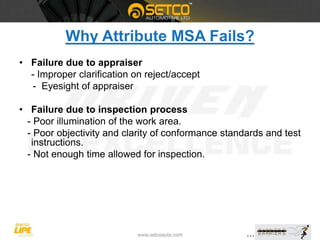

This document discusses measurement system analysis (MSA), including attribute MSA. It defines key MSA terms and describes the importance, types, and steps of attribute MSA. The document provides examples of calculating kappa value, miss rate, and false rate from attribute MSA data to evaluate measurement system capability. Reasons for attribute MSA failure include issues with appraisers or inspection processes.