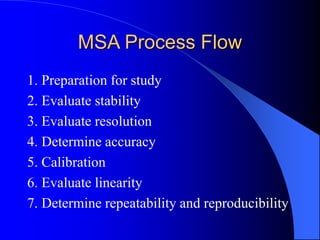

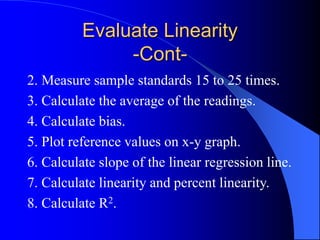

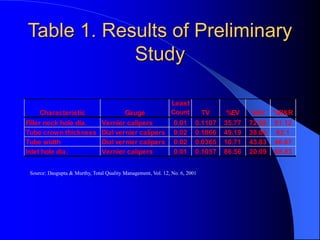

Measurement System Analysis (MSA) evaluates the statistical properties of measurement systems to ensure accuracy and precision, essential for maintaining product quality and minimizing defects. MSA is a mandatory requirement for QS 9000 certification and involves processes like stability evaluation, accuracy determination, and calibration. A case study illustrates that addressing measurement system issues can significantly reduce variation and improve manufacturing outcomes.