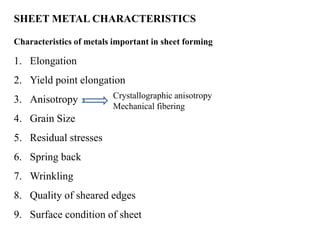

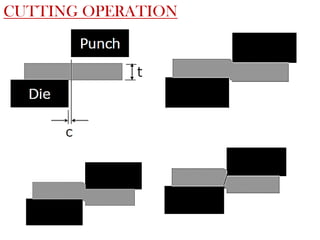

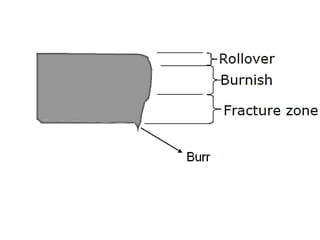

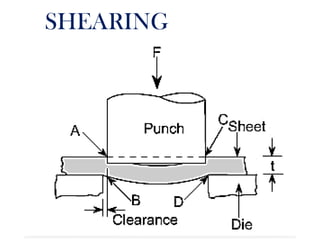

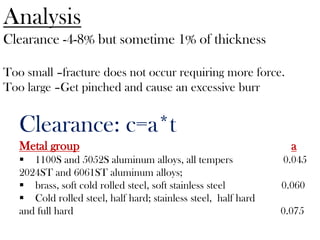

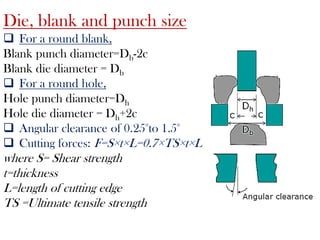

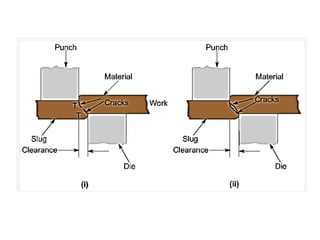

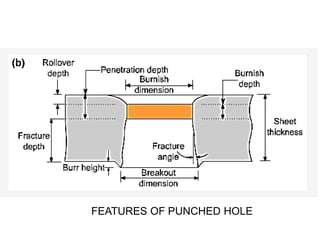

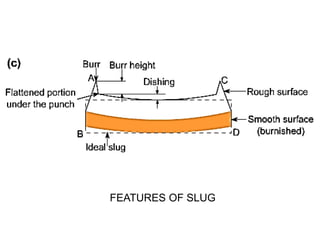

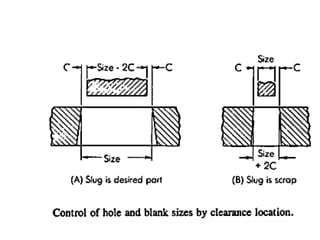

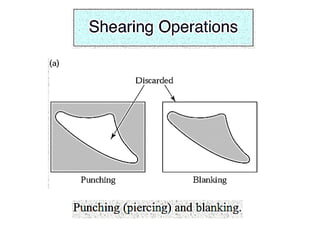

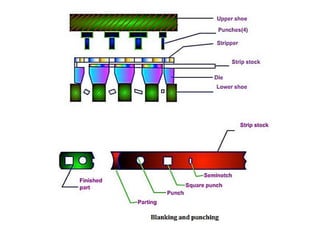

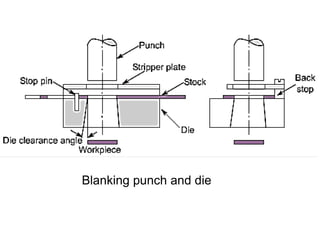

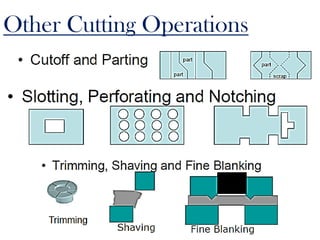

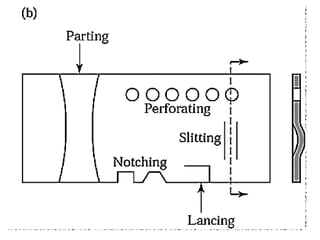

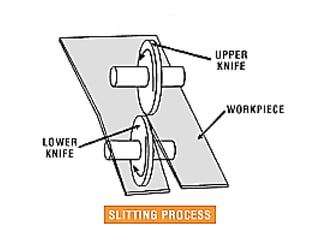

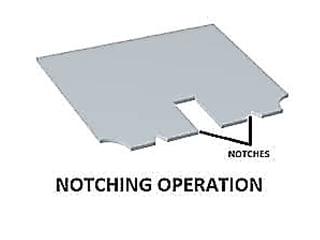

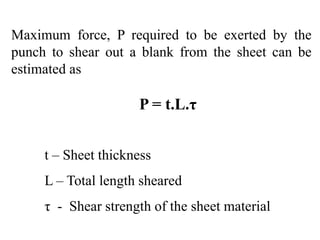

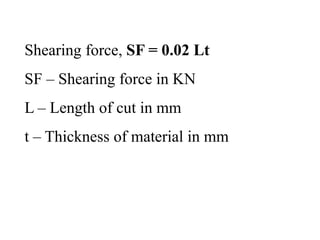

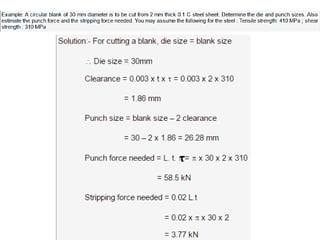

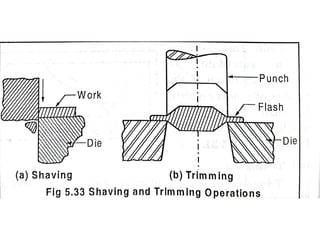

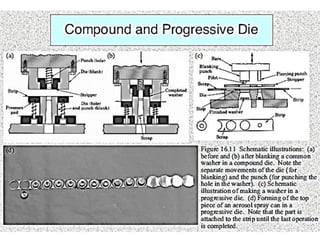

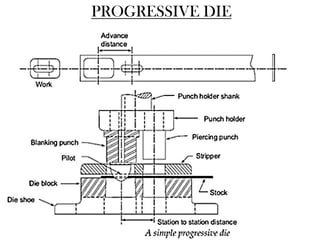

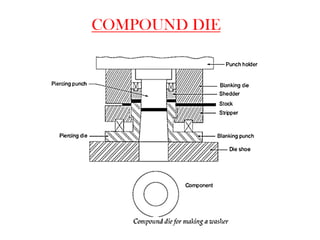

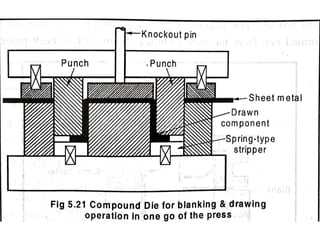

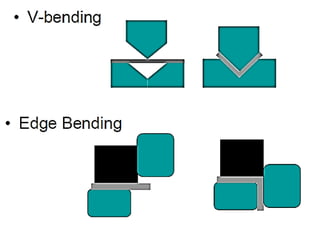

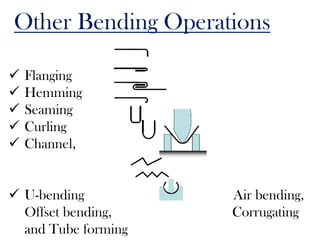

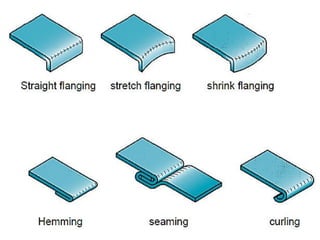

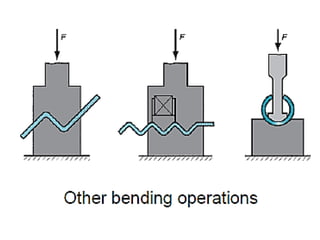

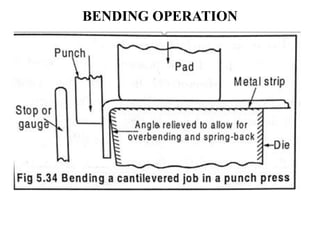

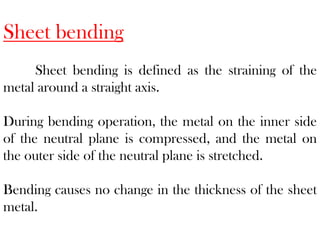

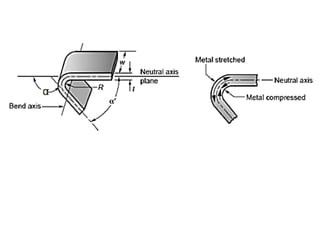

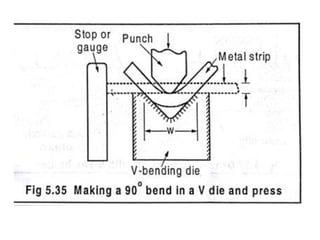

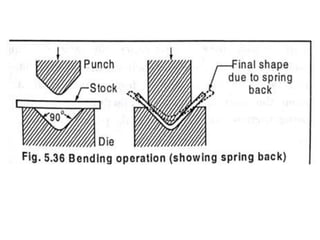

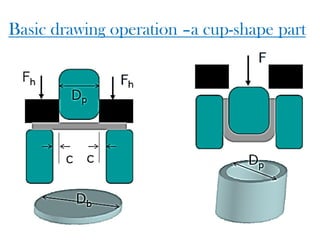

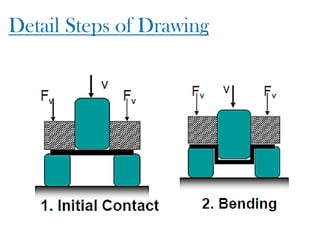

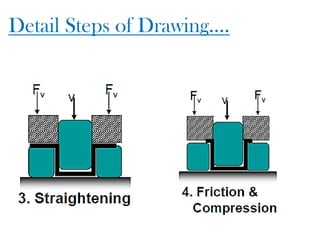

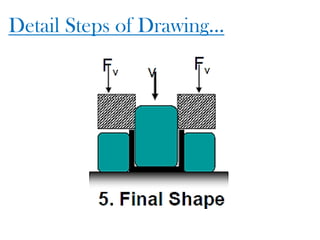

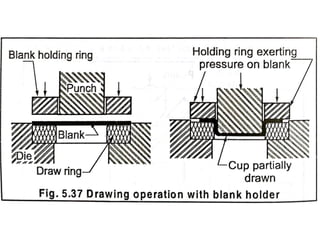

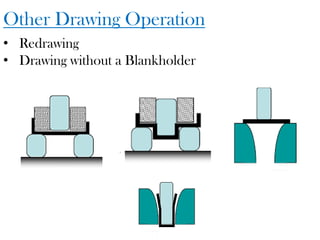

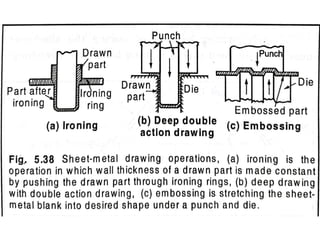

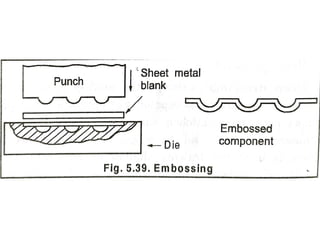

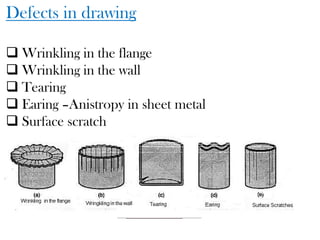

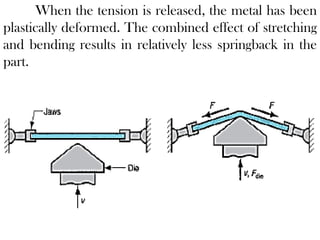

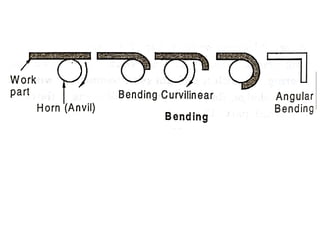

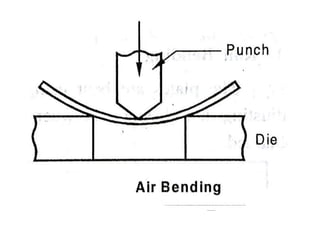

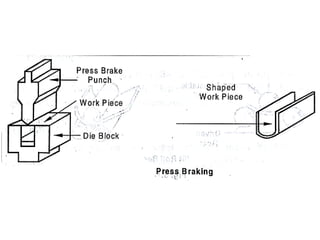

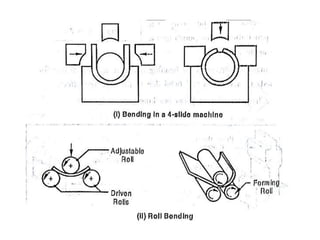

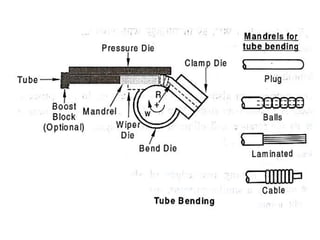

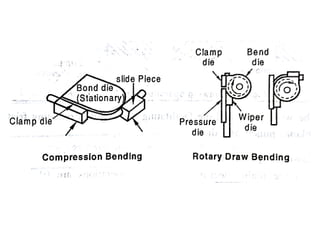

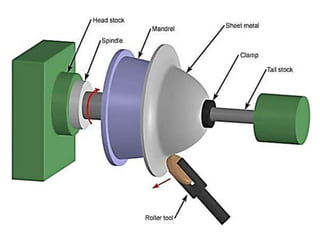

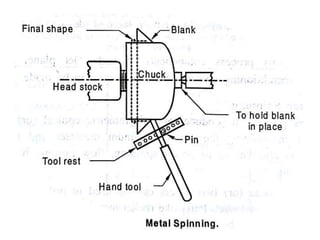

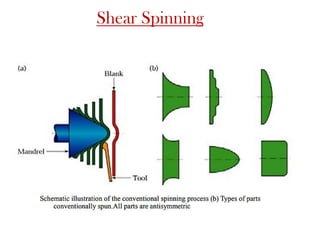

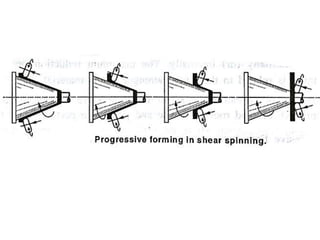

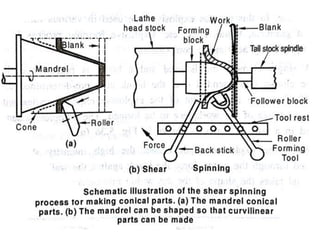

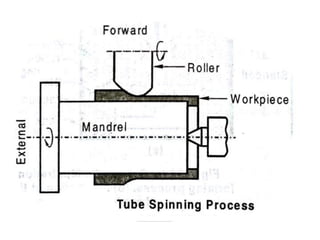

This document provides information on various sheet metal operations. It discusses cutting operations like shearing, blanking, and punching. Forming operations covered include bending, drawing, deep drawing, embossing, spinning, and roll forming. Common sheet metal parts include car bodies, aircraft fuselages, and cookware. Key terms defined are punch-and-die tooling, stamping presses, and stampings. Process steps and factors affecting operations like shearing, drawing, and bending are also outlined.