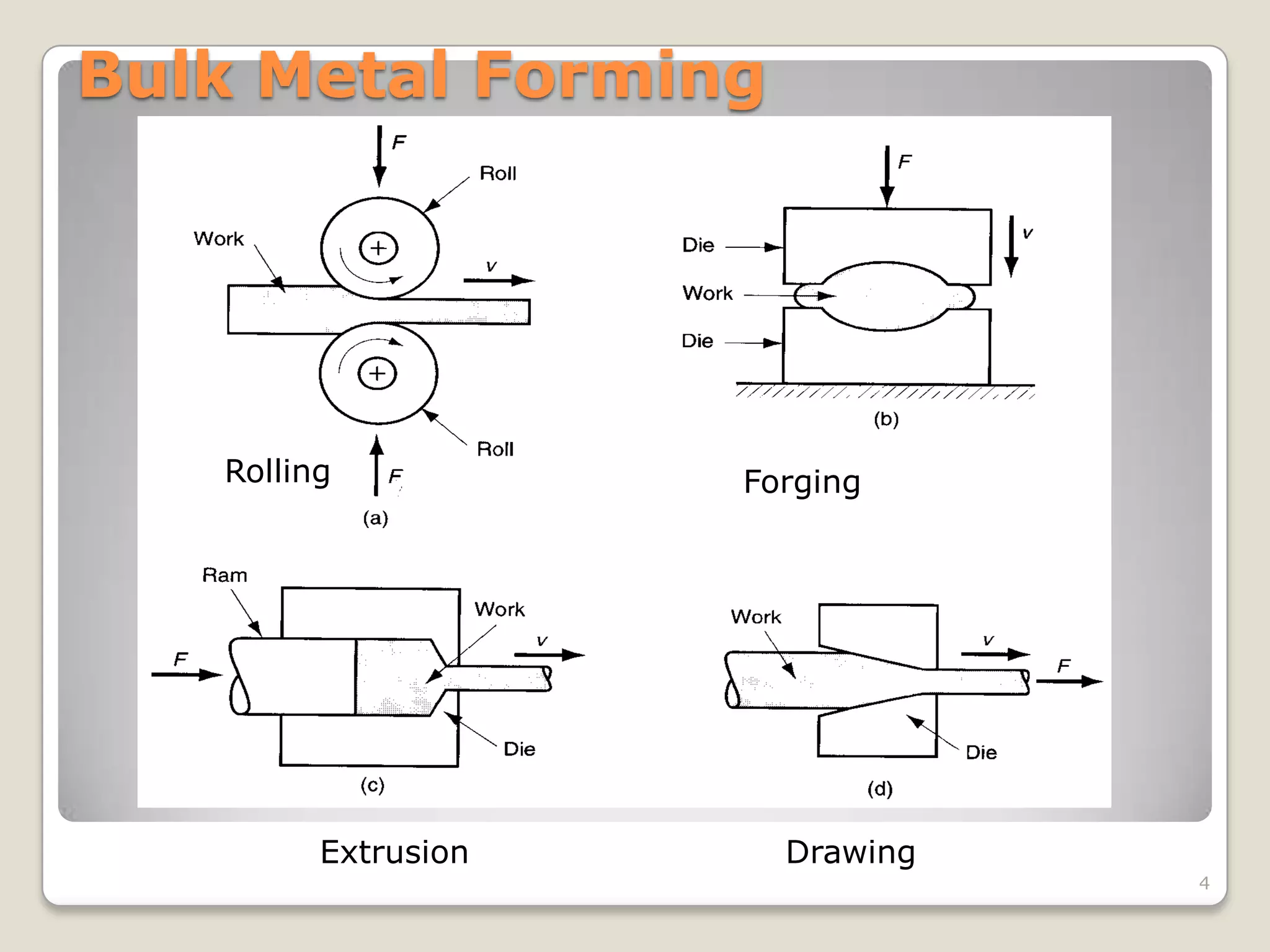

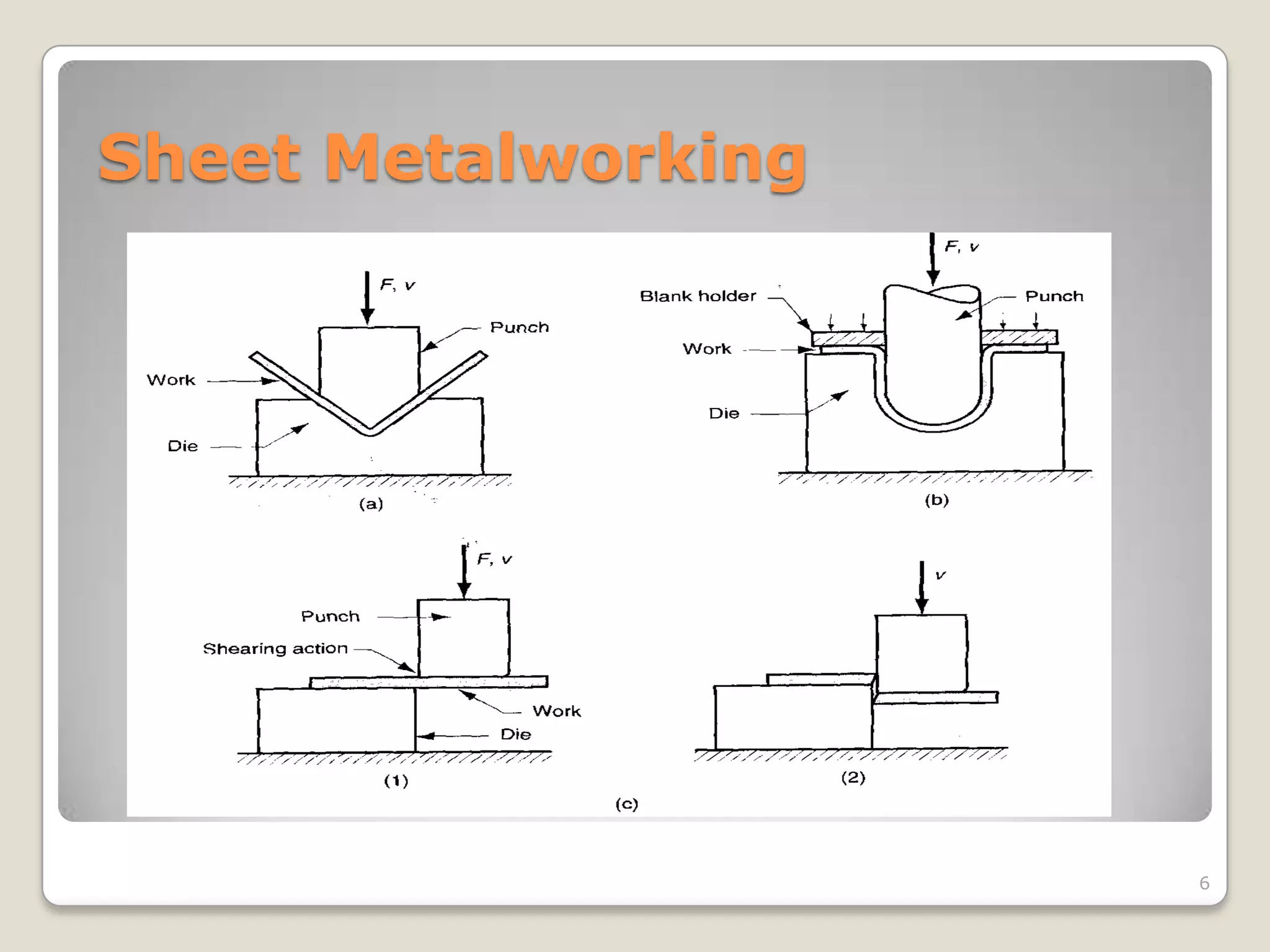

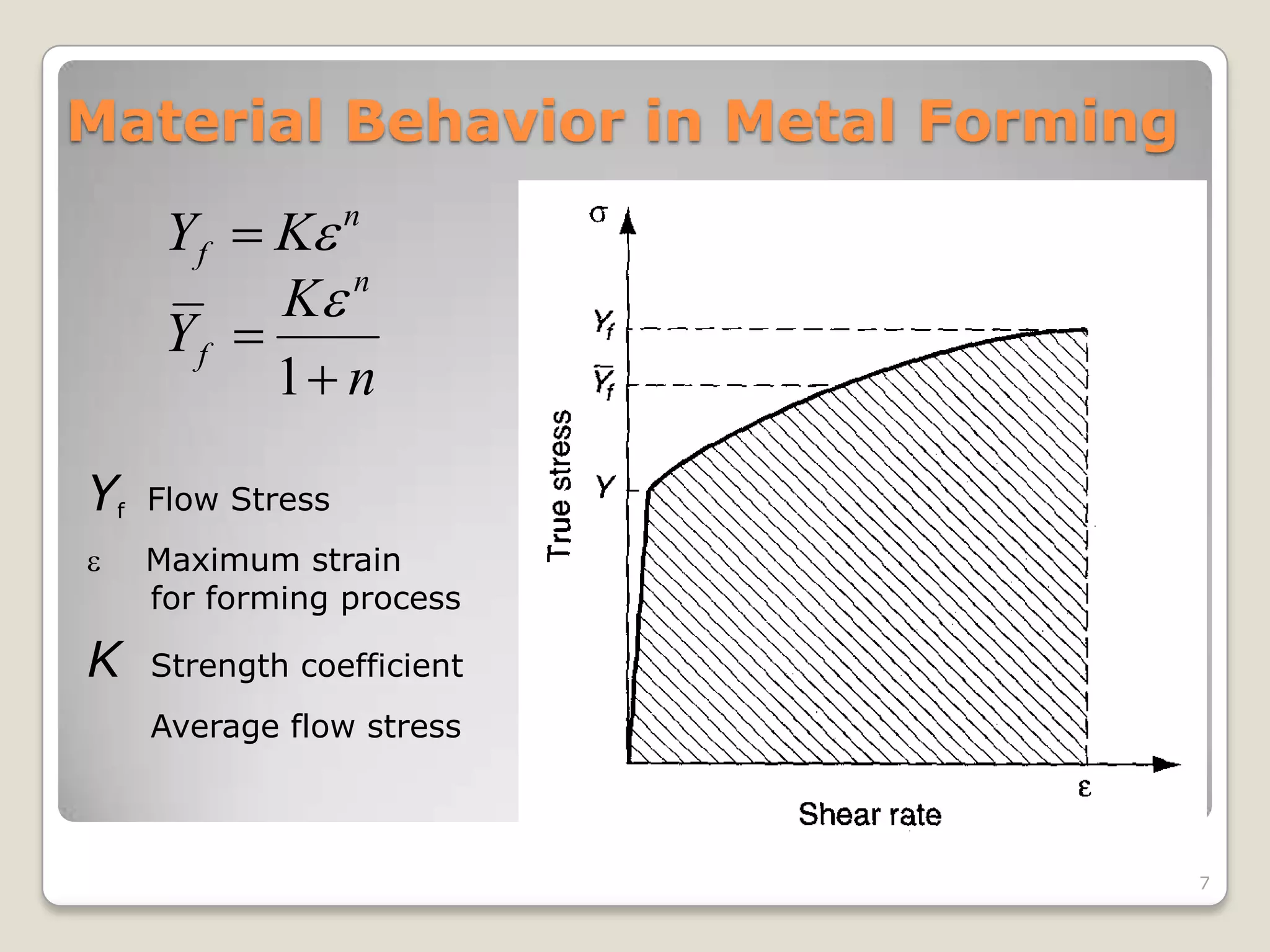

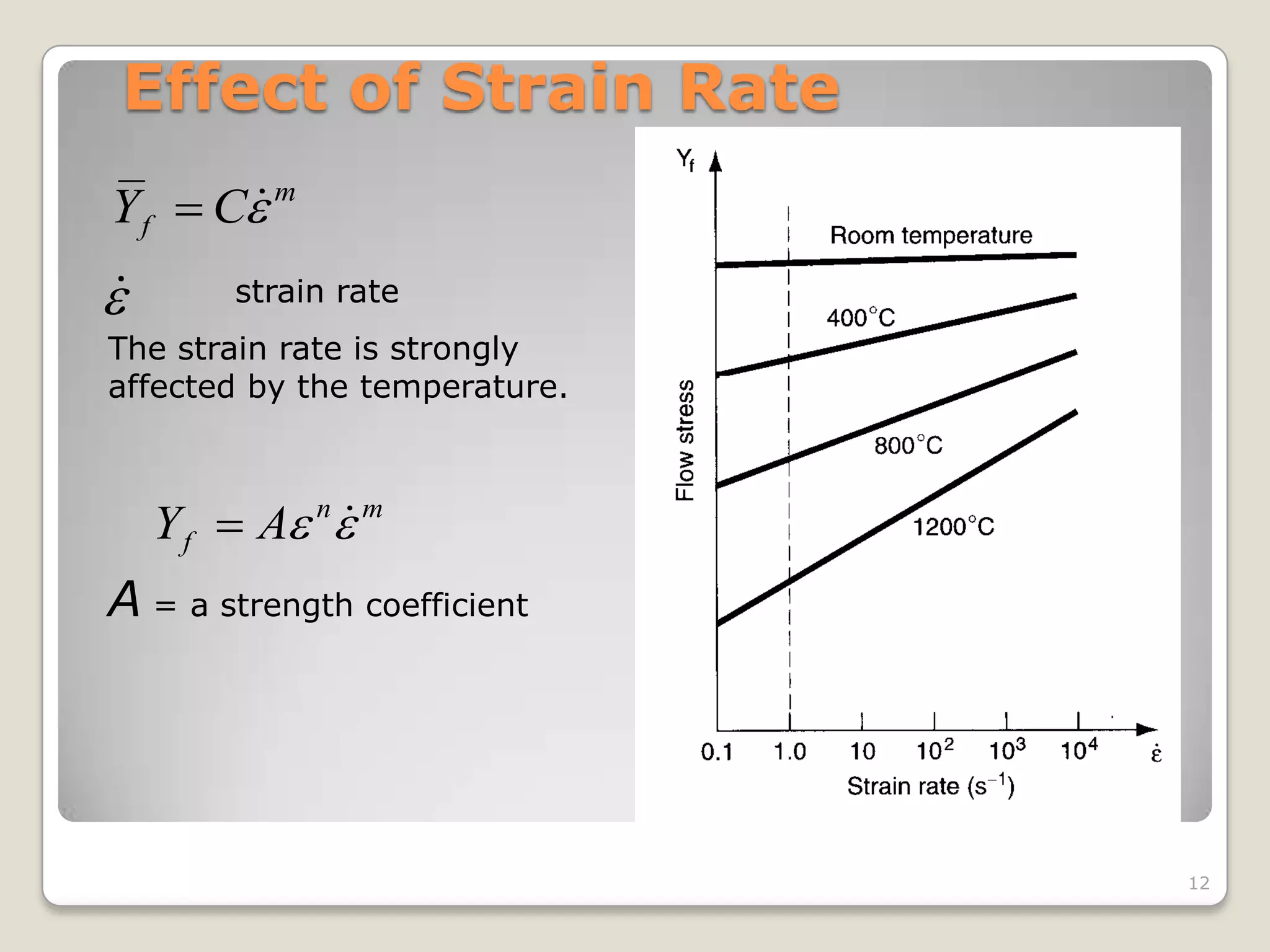

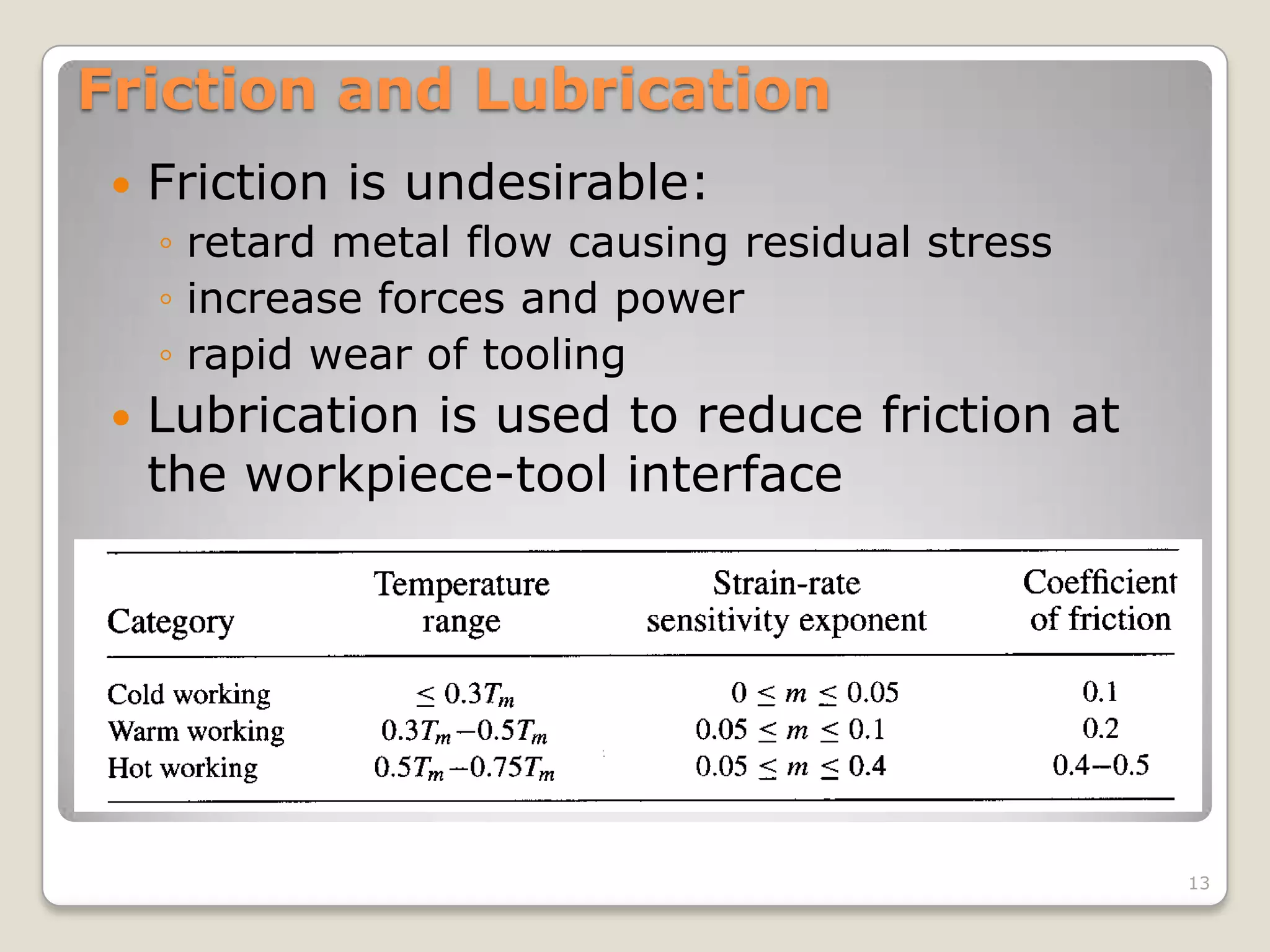

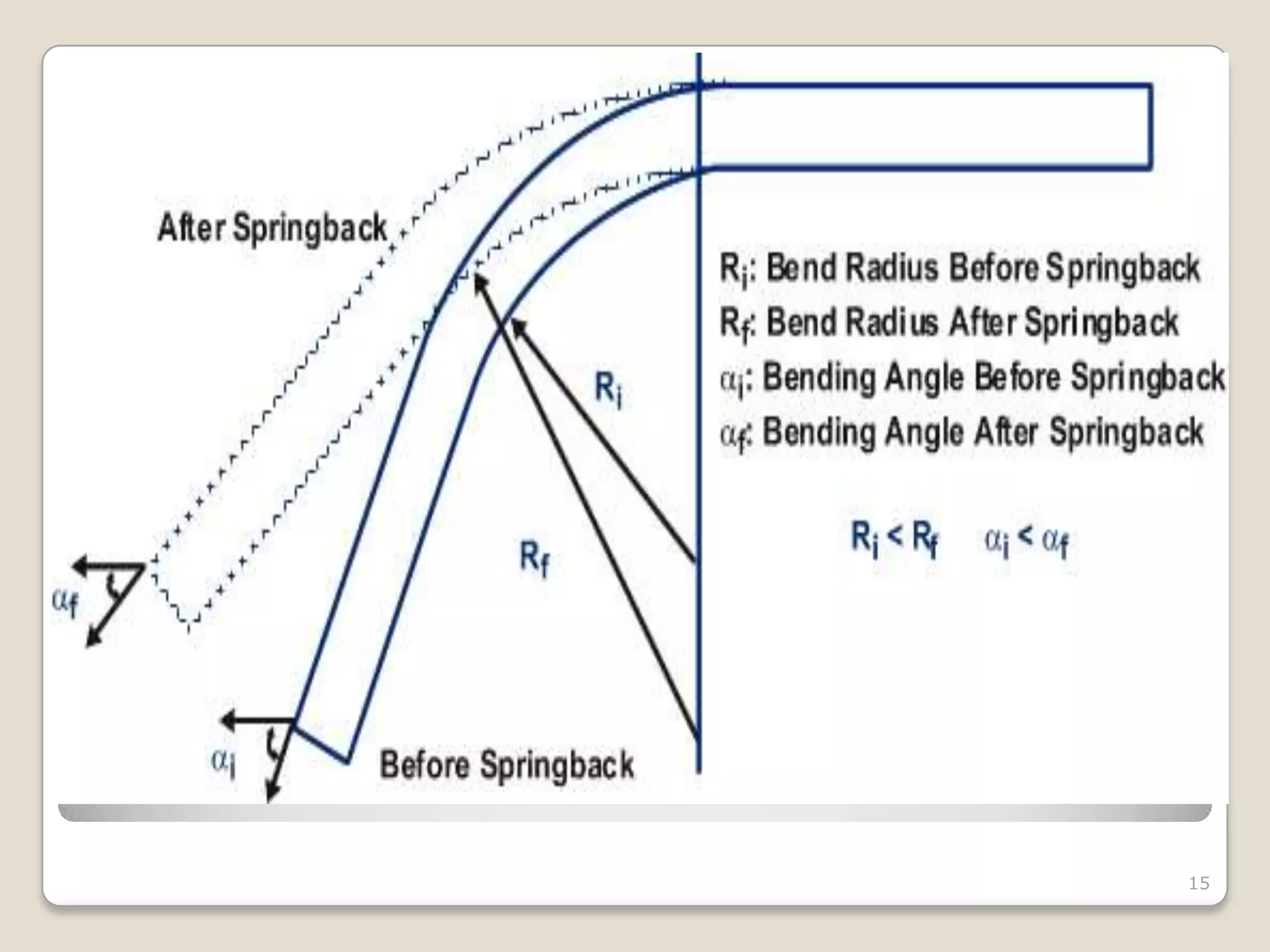

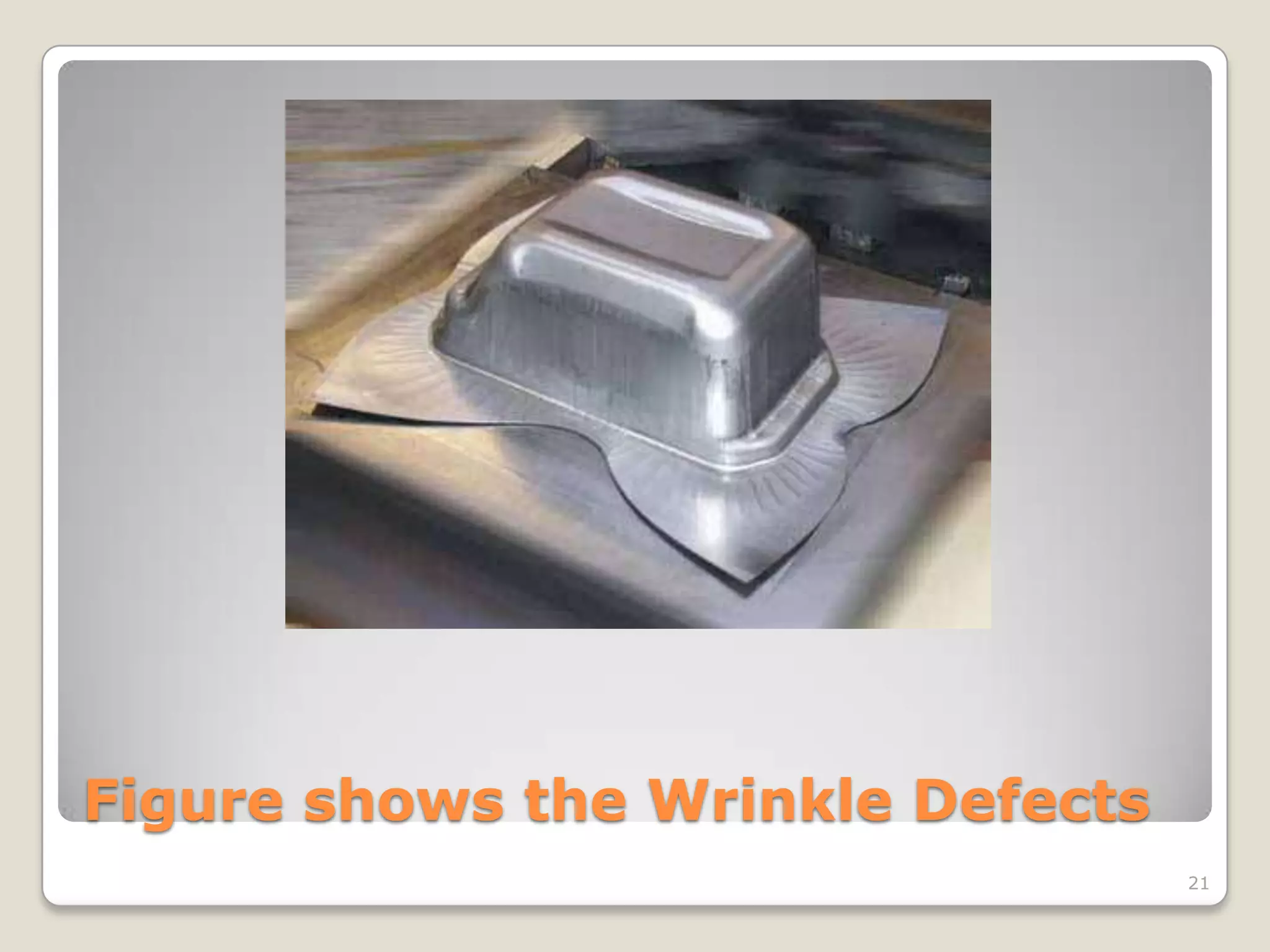

The document discusses various defects that can occur in metal forming processes. It describes the different types of bulk metal forming processes like rolling, forging, extrusion, and drawing. It also covers sheet metalworking processes like bending, drawing, and shearing. The document discusses factors that influence metal forming like material behavior, temperature, strain rate, friction, and lubrication. It explains defects like springback, wrinkles, and provides methods to minimize them.