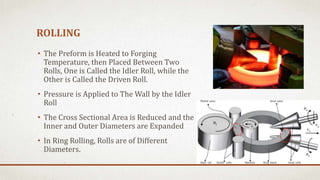

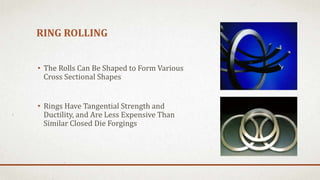

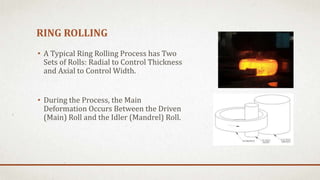

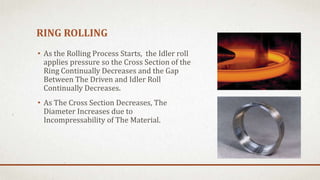

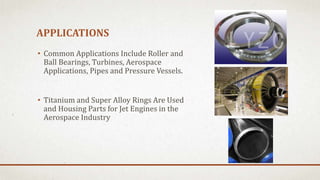

This document describes the process of manufacturing large diameter rings through forging and rolling operations. It discusses how the stock material is first upset forged and punched to create a preform, which is then heated and placed between rolls to be ring rolled. Ring rolling reduces the cross-sectional area and expands the inner and outer diameters to form the finished ring. Applications include bearings, turbines, and pipes. The advantages are uniform quality, smooth surface, and close tolerances, while disadvantages can include poor roll cavity filling and need for post-machining. A case study on high speed slewing rings for wind turbines is also presented.