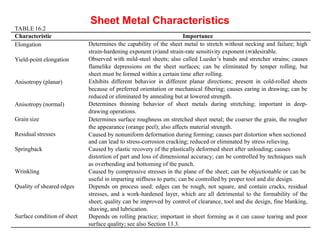

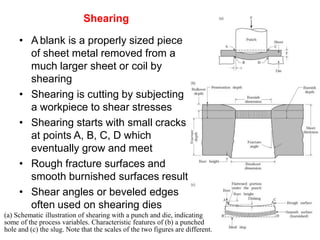

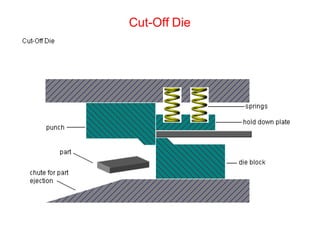

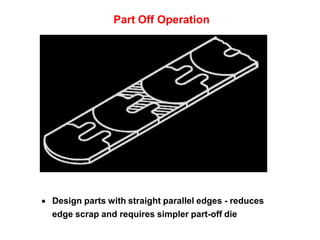

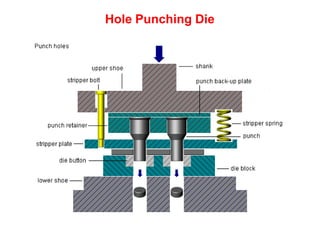

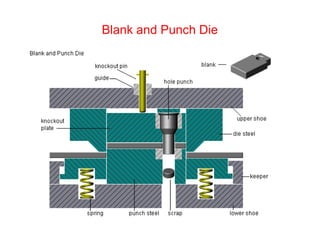

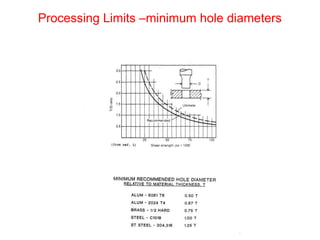

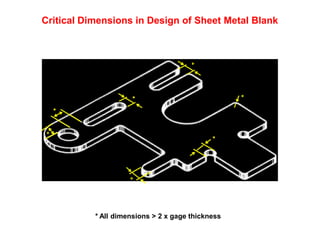

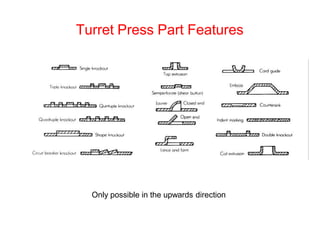

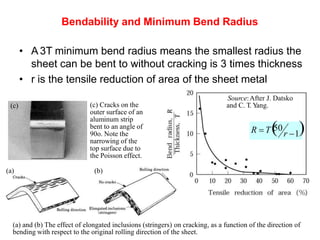

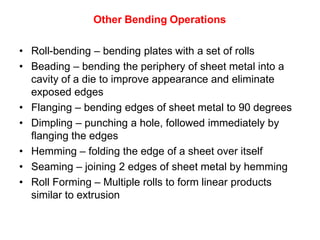

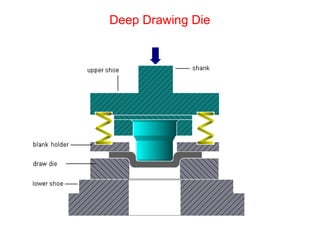

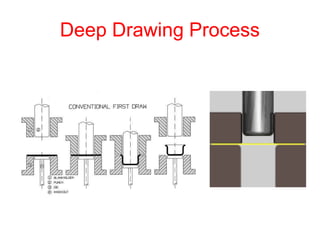

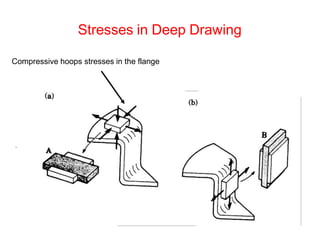

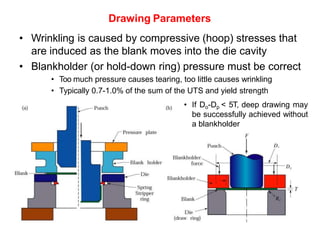

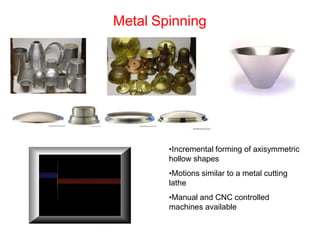

This document provides an overview of sheet metal forming processes. It begins by describing common applications of sheet metal forming such as metal desks, appliances, and car bodies. It then discusses various sheet metal forming operations like punching, blanking, bending, and deep drawing. The document discusses important sheet metal characteristics like formability, anisotropy, and springback that influence formability. It also summarizes various techniques for cutting, bending, and shaping sheet metal, as well as methods for minimizing scrap.