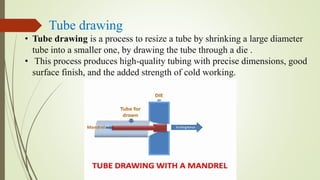

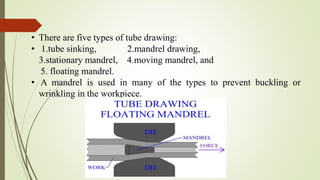

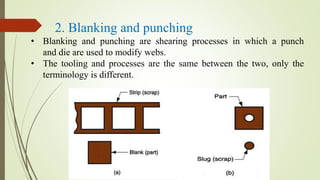

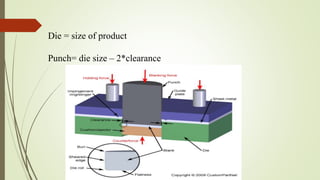

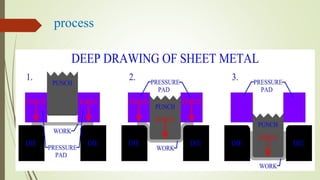

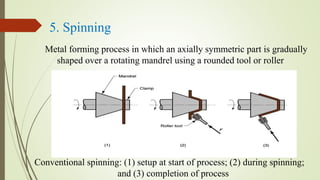

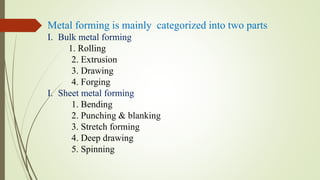

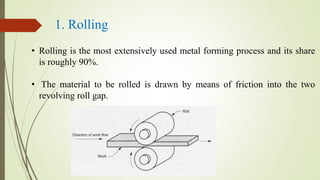

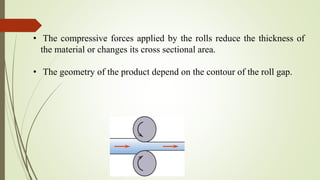

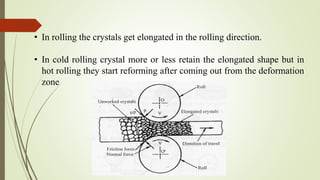

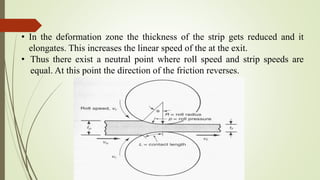

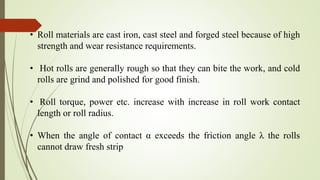

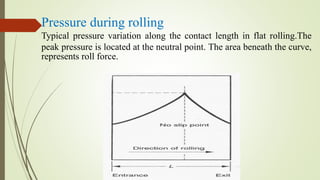

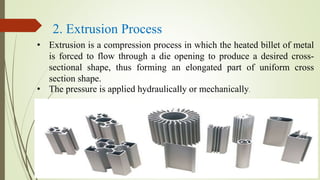

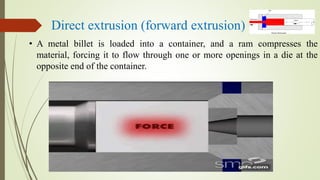

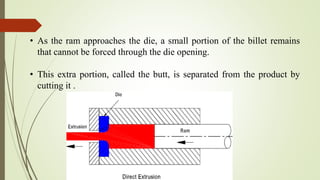

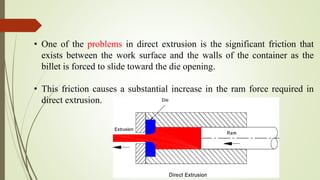

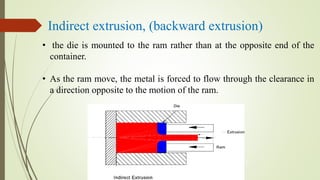

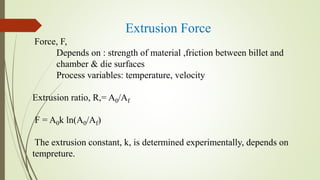

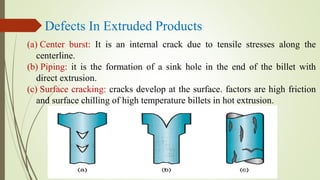

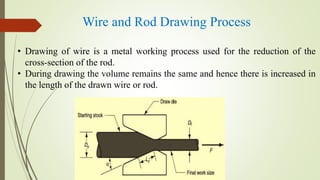

This document provides an overview of various metal forming processes including rolling, extrusion, drawing, forging, bending, punching, blanking, deep drawing, and stretch forming. It discusses the basic mechanisms, types, defects, and forces involved in each process. Key points covered include how rolling reduces thickness through plastic deformation between rolls, the differences between direct and indirect extrusion, how drawing reduces cross-sectional area by pulling metal through a die, and common defects that can occur in deep drawing like wrinkling, tearing, and earing.

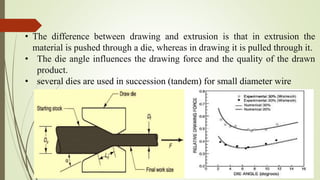

![Drawing Force

Frictionless

F = YavgAf ln(Ao/Af )

Friction & Redundant Work

F = YavgAf [(1+μ/α)ln(Ao/Af )+2α/3]

α is die angle in radians is die angle,

Yavg is yield strength of the material.](https://image.slidesharecdn.com/designformetalforming1-171113095153/85/Design-for-metal-forming-42-320.jpg)