Embed presentation

Downloaded 86 times

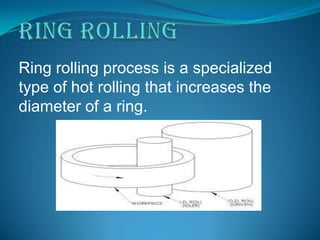

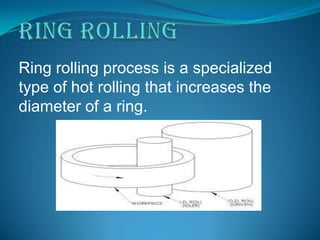

Rolling is a bulk deformation process that involves passing metal between two rollers to reduce the thickness of the metal. There are different types of rolling processes, including hot rolling where metal is heated and rolled to form thinner cross sections, cold rolling which increases hardness and strength but decreases ductility, and ring rolling which is a specialized hot rolling process that increases the diameter of rings.