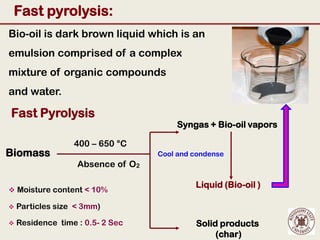

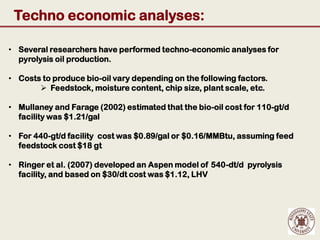

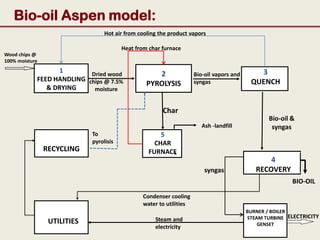

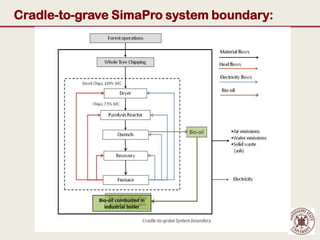

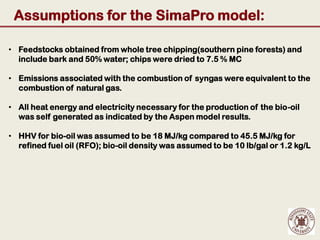

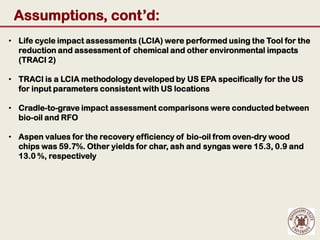

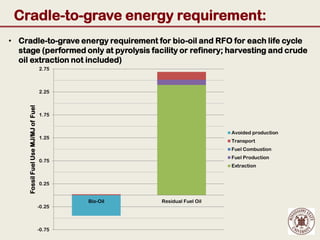

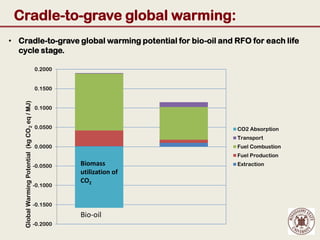

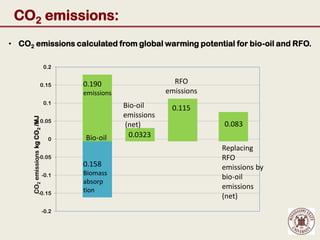

This document describes a study that used Aspen and SimaPro software to analyze the life cycle of producing liquid biofuel from fast pyrolysis of woody biomass. The study adapted an existing Aspen model of a 2000 tonne/day pyrolysis facility to develop a life cycle inventory. The SimaPro analysis found biofuel from pine chips had significantly lower greenhouse gas emissions than refined fuel oil. It also showed biofuel production was near carbon neutral and could reduce CO2 emissions by substituting for refined oil. Energy required for biofuel production was mostly self-generated.