The document summarizes research on co-feeding fibrous biomass and coal into entrained flow gasifiers. It discusses the challenges of biomass as a fuel source and describes how torrefaction can be used as a pre-treatment step to improve biomass properties for gasification. It then outlines the Energy research Centre of the Netherlands' work in developing torrefaction technology, modeling slagging and fouling behavior, and testing biomass and coal mixtures using a lab-scale combustion simulator.

![Modelling slagging and fouling behaviour

Slagging behavior as function ofelements in biomass for fluxed clean wood fuel

wt% ash mixing slag as f(T) and coal

wt% ash elements in slag as f(T) for fluxed clean wood fuel

100

100

90

slag as wt% of fuel ash (incl. flux)

90

slag as wt% of fuel ash (incl. flux)

Original clean wood

80

80

70

70 Silica/fuel ash=0.25 kg/kg

60

60

50

Silica/fuel ash=0.75 kg/kg

50 40

40 30 Silica/fuel ash=1.25 kg/kg

30 20

20 10 Silica/alumina/fuel

10 0 ash=0.5/0.45 kg/kg

0 800 1000 1200 1400 1600 18

800 1000 1200 1400 1600 1800 T [°C]

T [°C]

17 GAP & Coal Chemicals Conference 8-9 June 2011 - Beijing](https://image.slidesharecdn.com/2011beijingcofiringbiomassandcoalineggasifiers-13308590116413-phpapp02-120304050636-phpapp02/85/Cofiring-biomass-amp-coal-17-320.jpg)

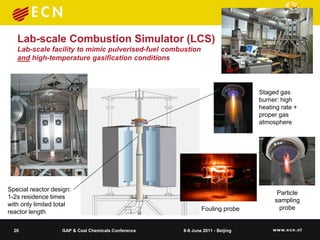

![Labscale Combustion & gasification simulator (LCS)

Residence time/temperature profile (example)

LCS PF facility (controlled conditions, 5 ms up

to 2500ms, 600-1550°C, gas composition)

Temperature [°C]

1000 1200 1400 1600

0 20

90

0,1

0,2 Burner Area

0,3 210

Residence time [ms]

Distance [m] 0,4

0,5

0,6

0,7

1300

0,8

0,9

Furnace Exit

1

18 GAP & Coal Chemicals Conference 8-9 June 2011 - Beijing](https://image.slidesharecdn.com/2011beijingcofiringbiomassandcoalineggasifiers-13308590116413-phpapp02-120304050636-phpapp02/85/Cofiring-biomass-amp-coal-18-320.jpg)

![Labscale Combustion &

gasification simulator (LCS)

Particle sampling

Fractionated samples (lab- & full-scale)

obtained with cascade impactors (CI):

Study release inorganics and

aerosol formation

Provides composition and

morphology of each size 70

fraction 60

plate

stage 1

stage 2

In short: particle sampling

stage 3

weight fraction [% w/w]

50 stage 4

stage 5

allows investigation of 40 stage 6

stage 7

stage 8

all inorganic particles that 30 stage 9

stage 10

enter syngas cooler 20

10

0

25 GAP & Coal Chemicals Conference 8-9 June 2011 - Fe

S Beijing

Na Mg Al Si P Cl K Ca](https://image.slidesharecdn.com/2011beijingcofiringbiomassandcoalineggasifiers-13308590116413-phpapp02-120304050636-phpapp02/85/Cofiring-biomass-amp-coal-25-320.jpg)