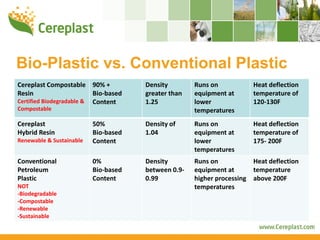

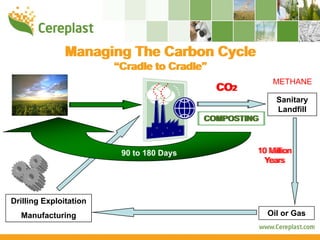

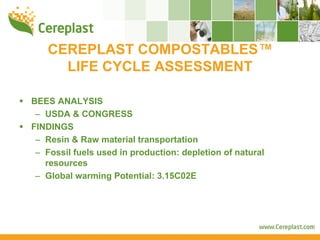

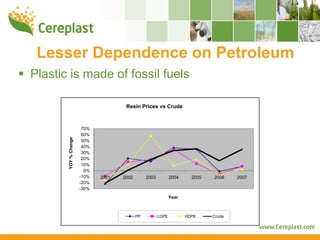

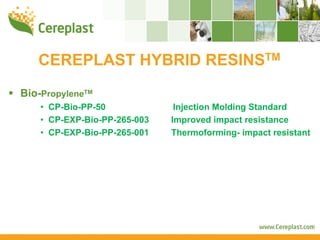

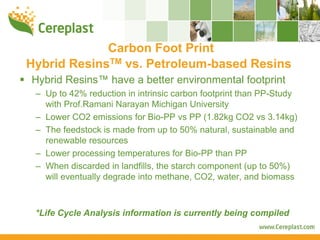

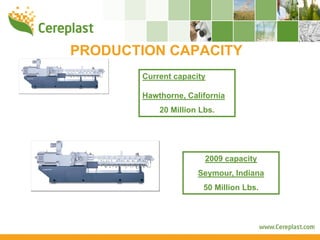

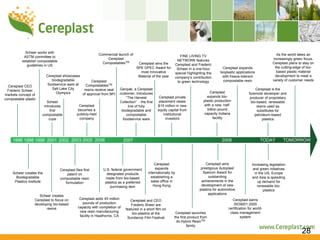

Cereplast is a leading manufacturer of bio-resins that are more sustainable alternatives to petroleum-based plastics. They have developed two families of bio-resins - compostable resins for single-use items and hybrid resins for durable applications. Cereplast aims to reduce dependence on fossil fuels and promote sustainability through bio-based and renewable resins.