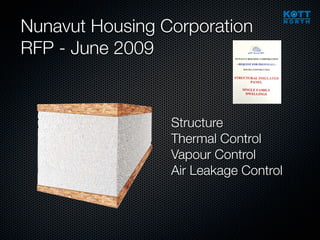

This document discusses social housing needs in Nunavut, Canada. It notes that Nunavut has over 30,000 people spread across 26 remote communities with no road connections and housing is a major challenge. Nearly half of the approximately 8,500 dwellings do not meet Canadian standards and there is currently a shortage of 3,000 units. A structural insulated panel system was proposed that provides high insulation values of R-40 walls and R-50 floors and roofs, while allowing for extremely tight construction with negligible air leakage. Modeling showed this solution could reduce annual heating costs by over 40% compared to the existing construction method.