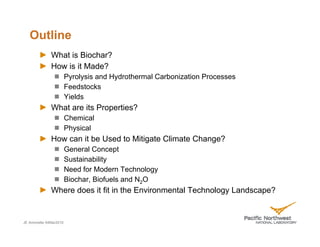

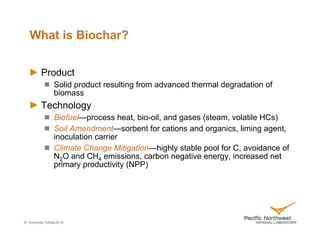

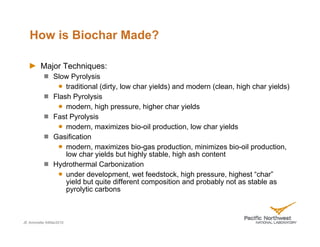

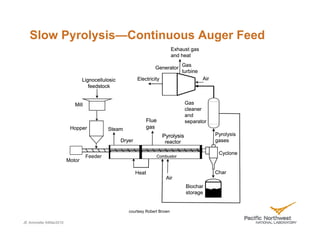

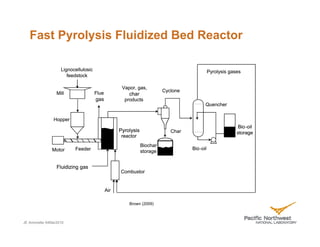

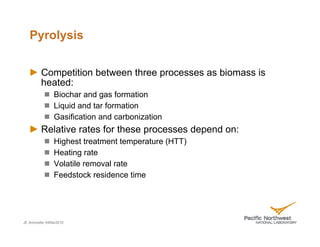

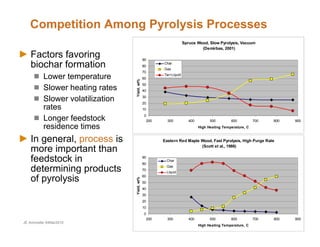

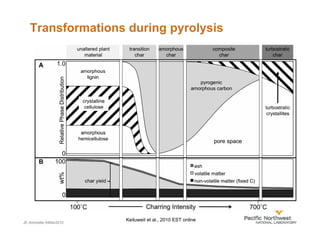

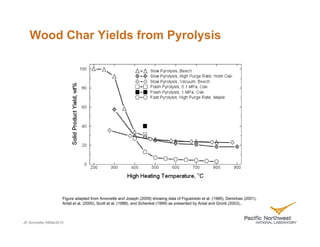

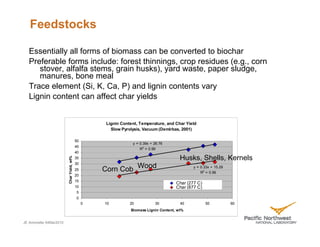

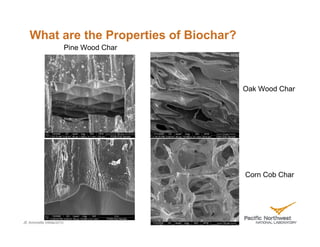

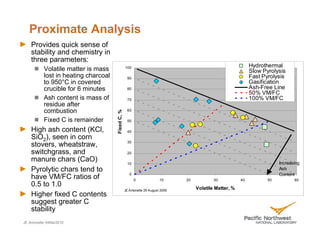

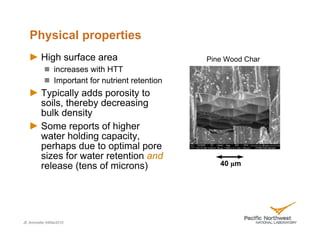

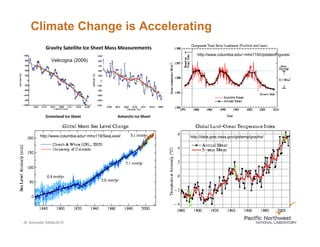

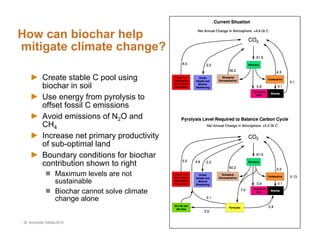

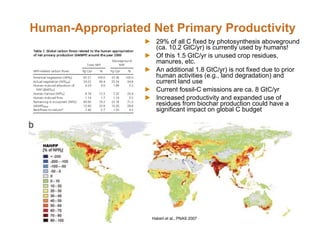

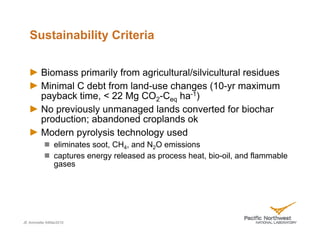

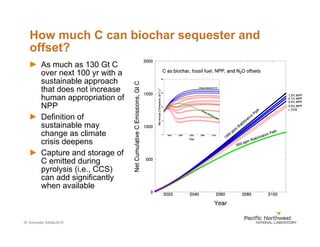

This document provides an overview of biochar, a solid product derived from the thermal degradation of biomass, detailing its production methods, properties, and potential uses in climate change mitigation. Key production techniques include slow pyrolysis, fast pyrolysis, gasification, and hydrothermal carbonization, each affecting yield and stability differently. The document emphasizes biochar's role in enhancing soil fertility, reducing greenhouse gas emissions, and improving nutrient retention, while also outlining sustainability criteria for its production.