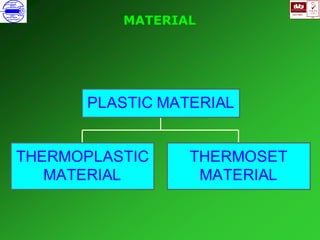

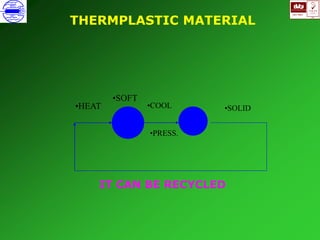

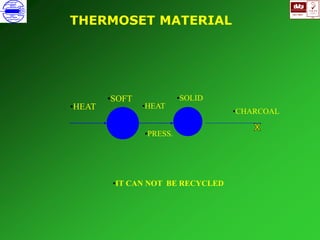

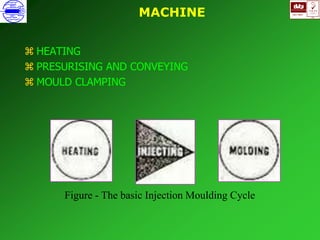

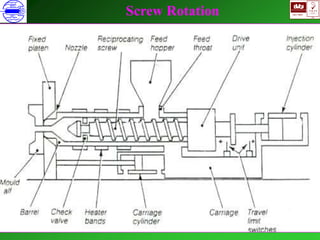

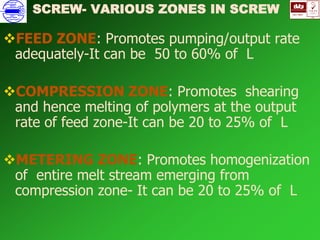

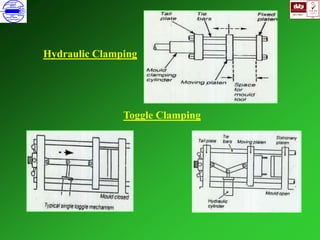

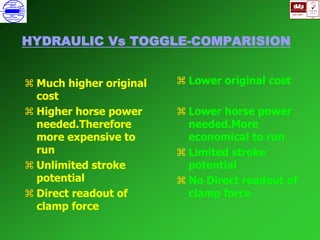

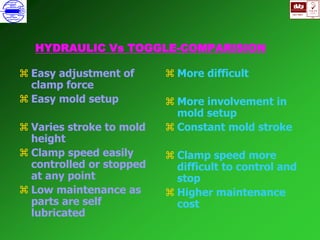

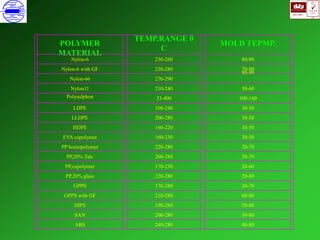

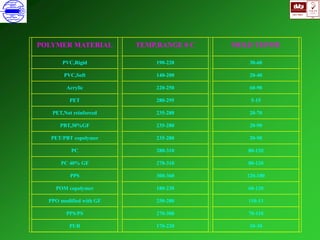

The document discusses the injection moulding process. It describes the key resources needed which include material, machines, moulds, and manpower. It explains the differences between thermoplastic and thermoset materials. The document outlines the injection moulding cycle and provides examples of common products made through this process. It also discusses important considerations for material, machines, moulds, and temperature ranges.