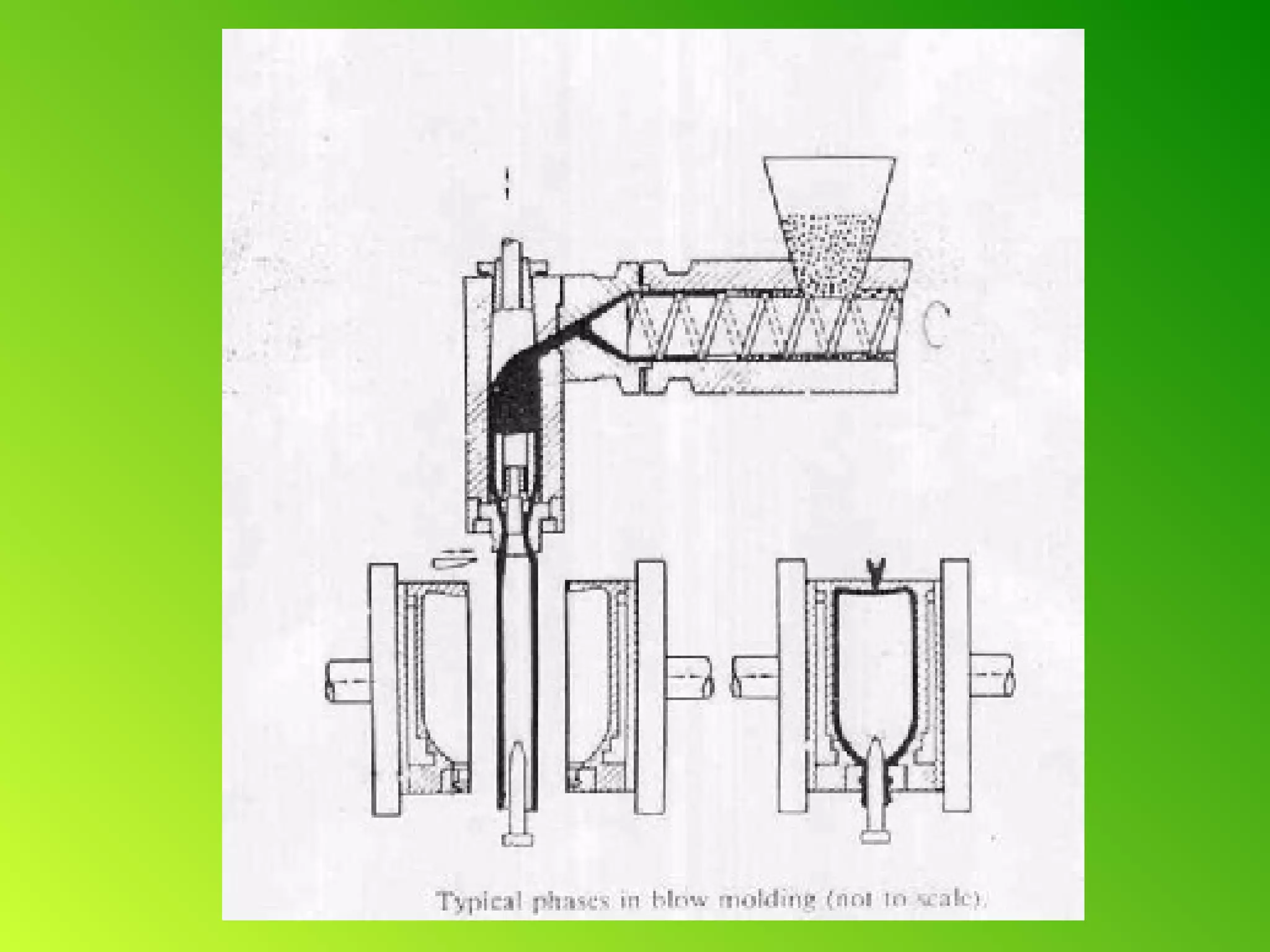

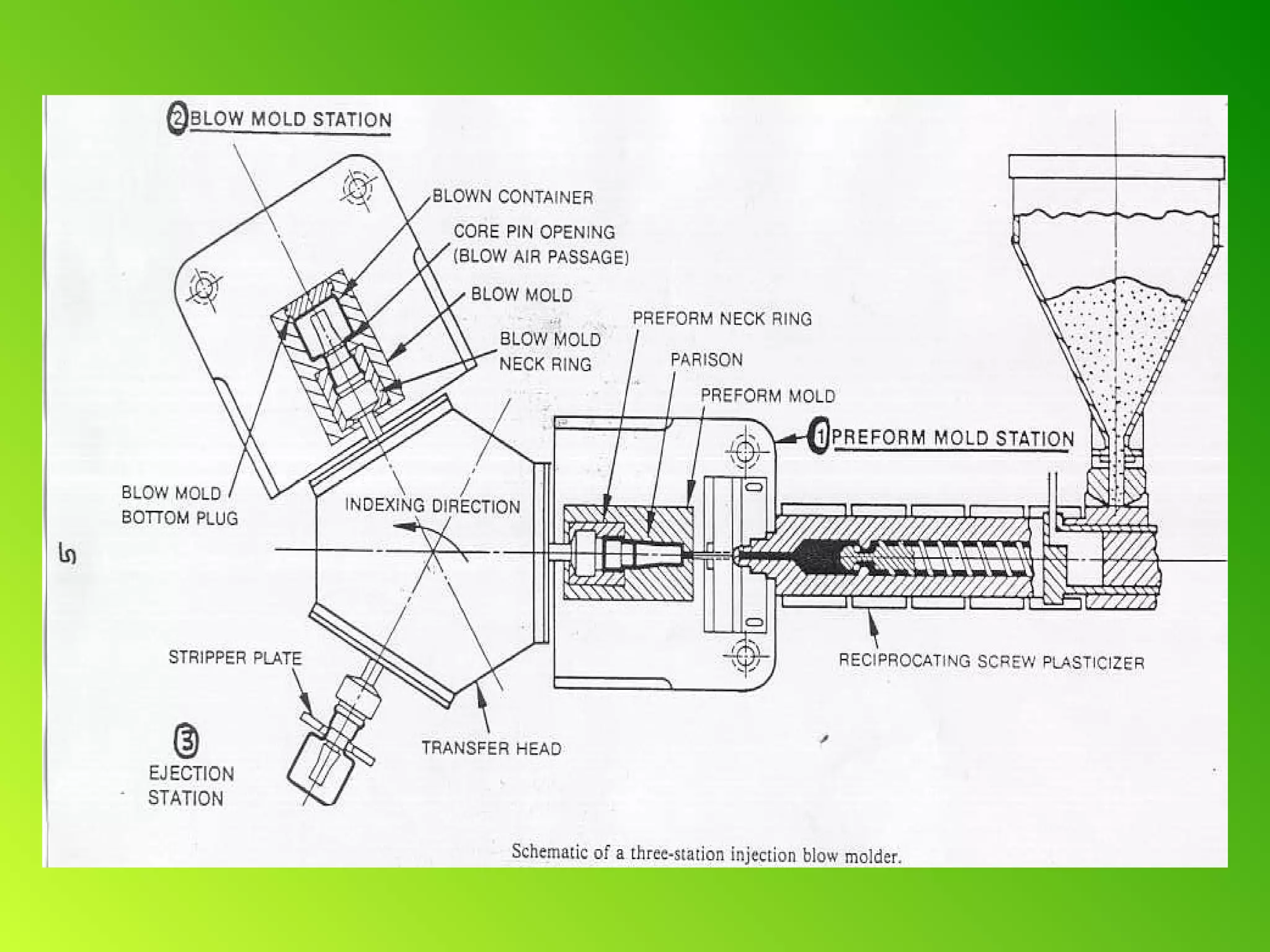

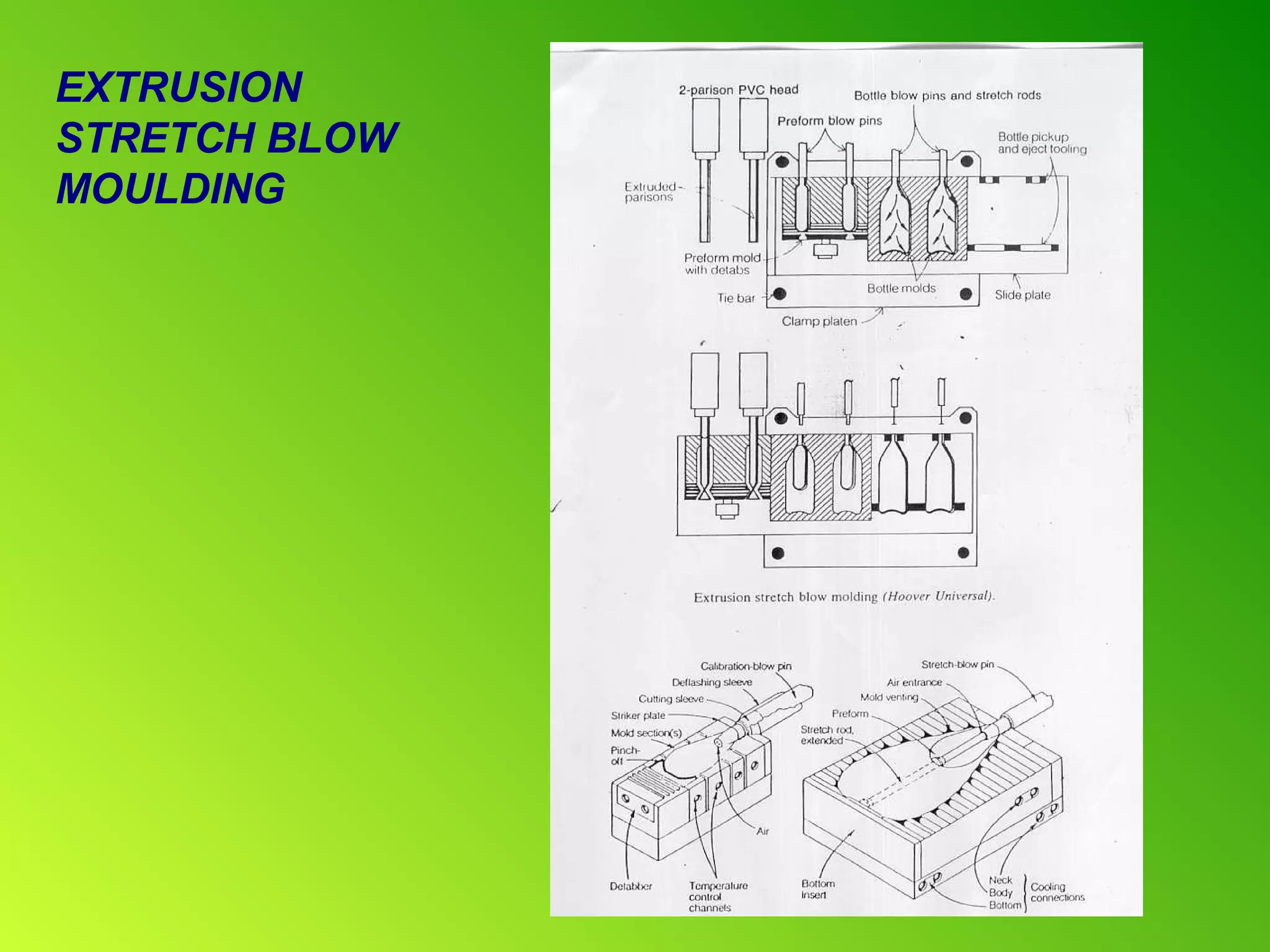

This document discusses blow moulding, which uses compressed air to form hollow plastic products like bottles from thermoplastics. It describes the advantages of blow moulding over injection moulding, including its ability to produce irregular shapes with variable wall thickness at lower pressures. Extrusion blow moulding and injection blow moulding are the main types discussed, along with stretch blow moulding. The extrusion process and machinery are explained in detail. Common plastic materials used are also listed for small and large products.