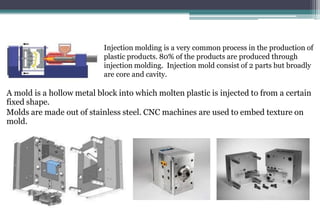

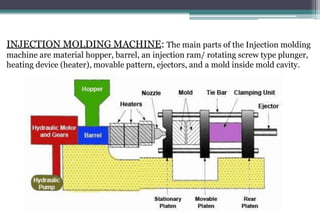

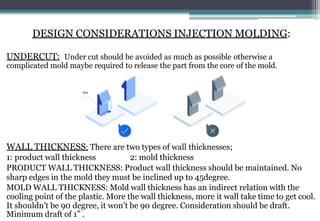

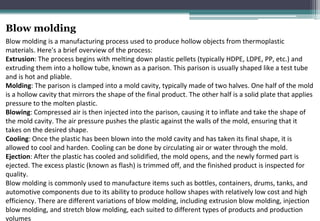

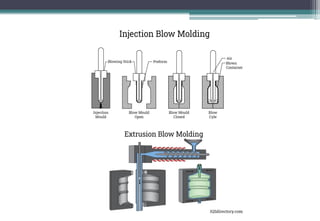

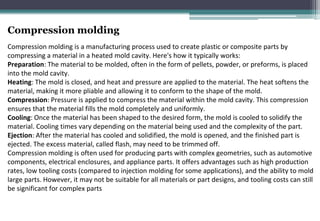

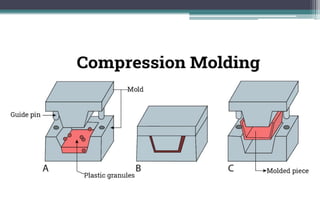

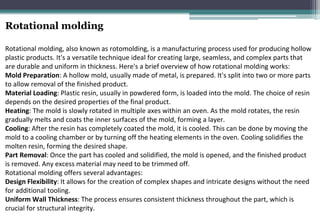

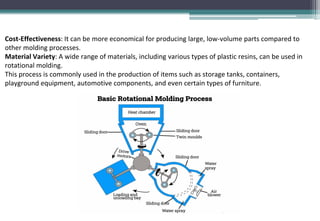

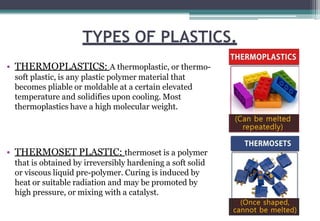

The document is a final report on plastic materials, detailing their properties, manufacturing processes, including injection molding, blow molding, compression molding, thermoforming, and rotational molding. It covers types of plastics, their applications, and advantages of different molding techniques. The report also highlights various plastics such as thermoplastics, thermoset plastics, and specific materials like acrylic, polystyrene, and fiberglass.