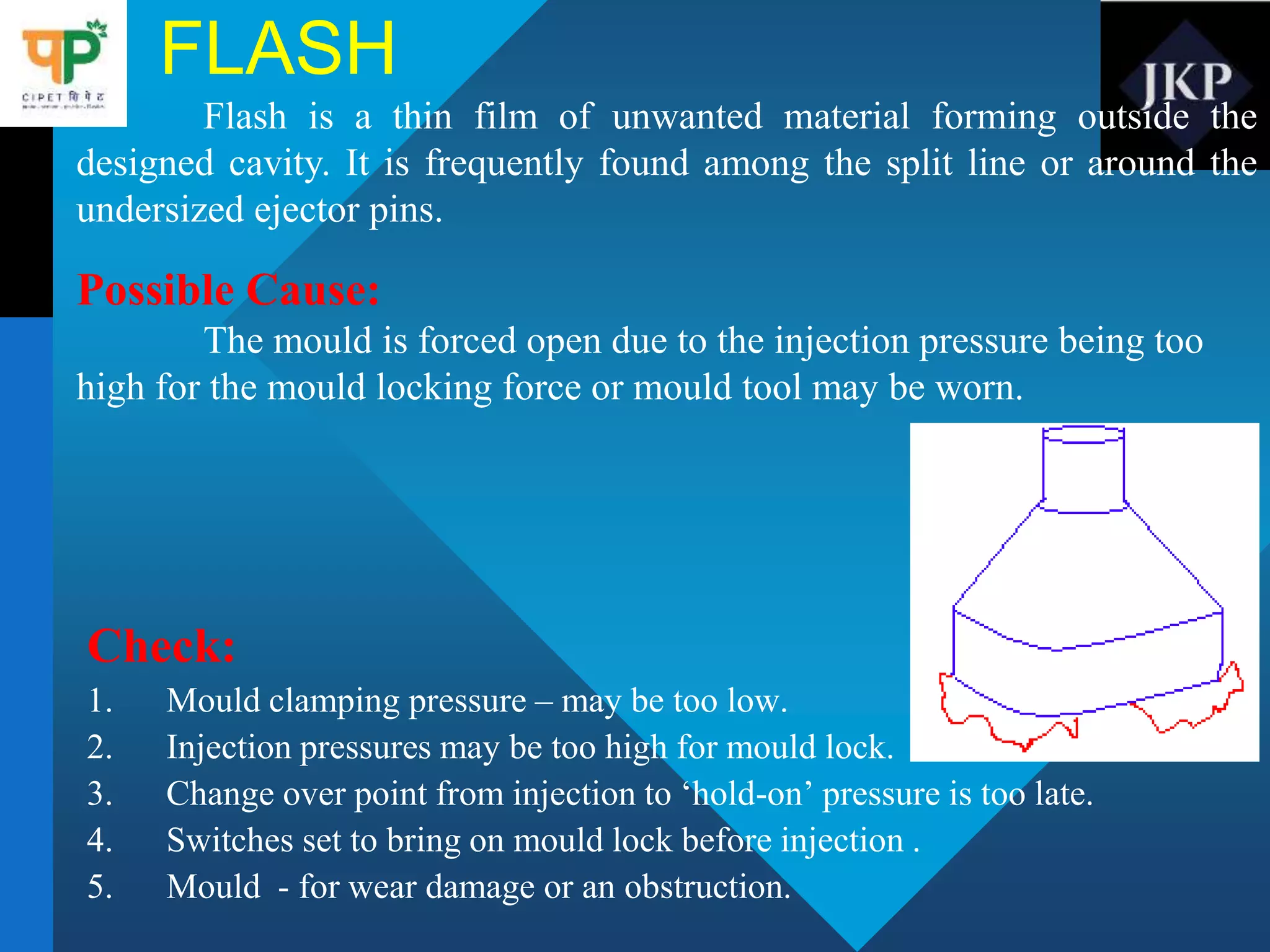

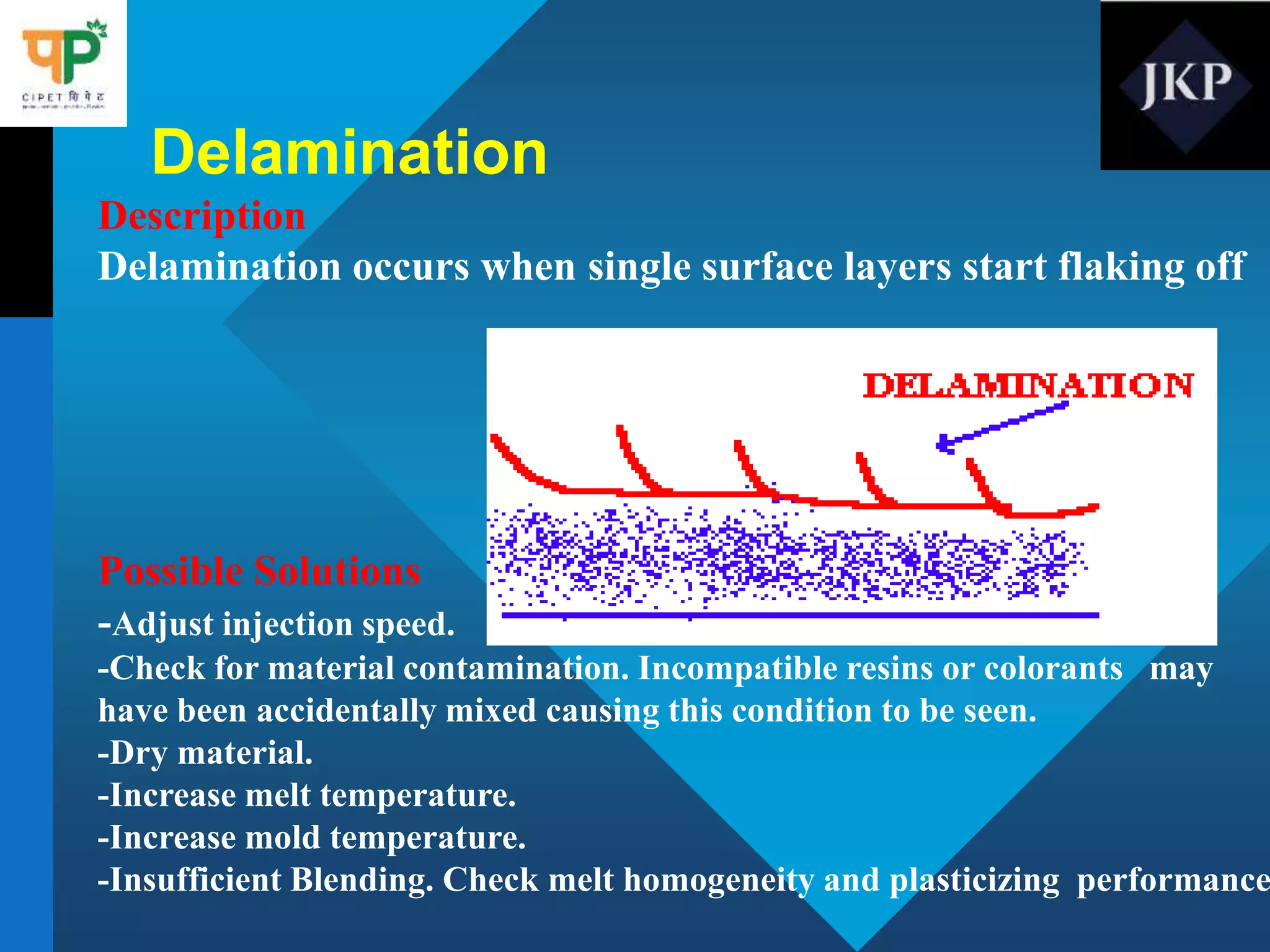

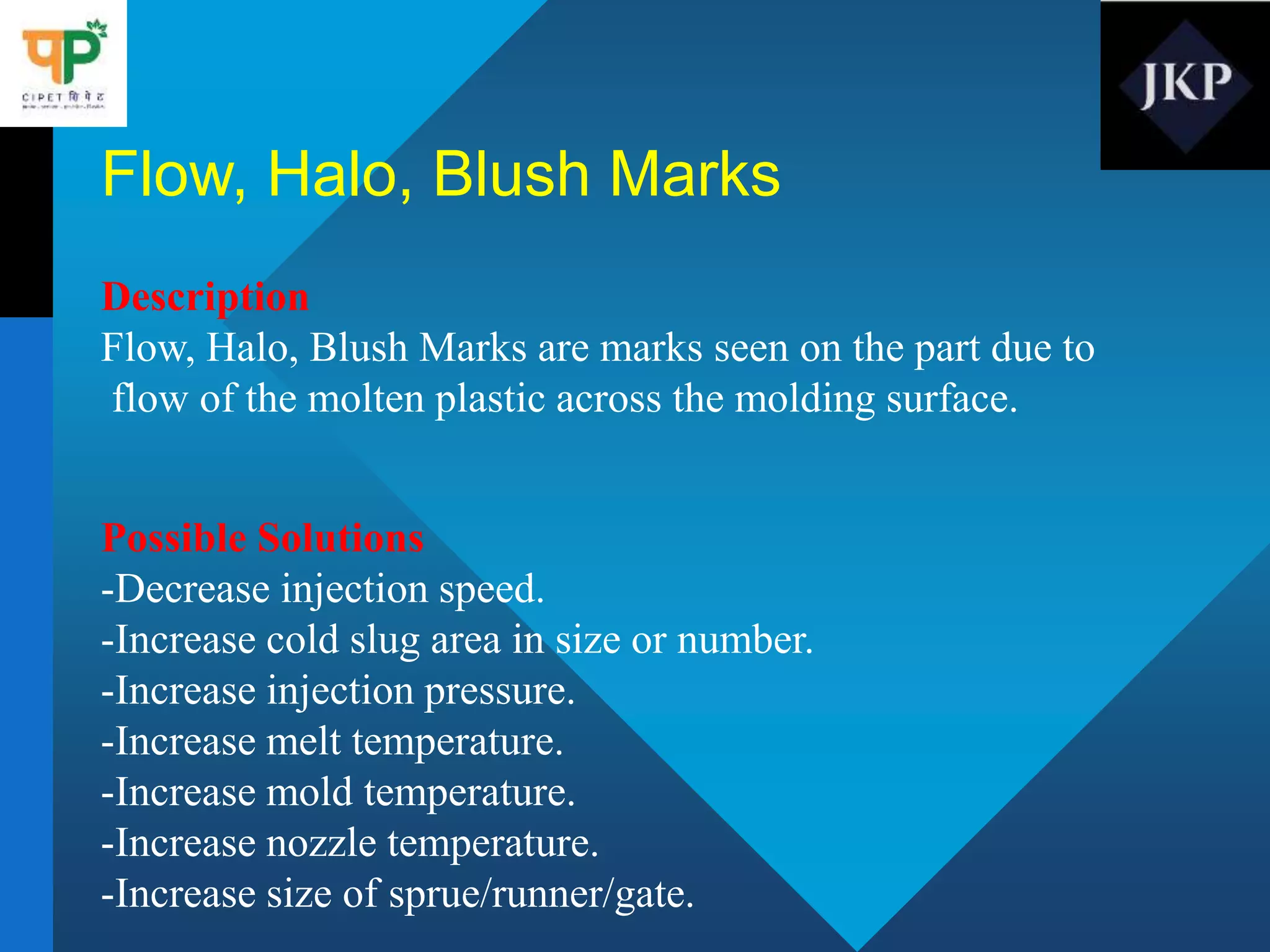

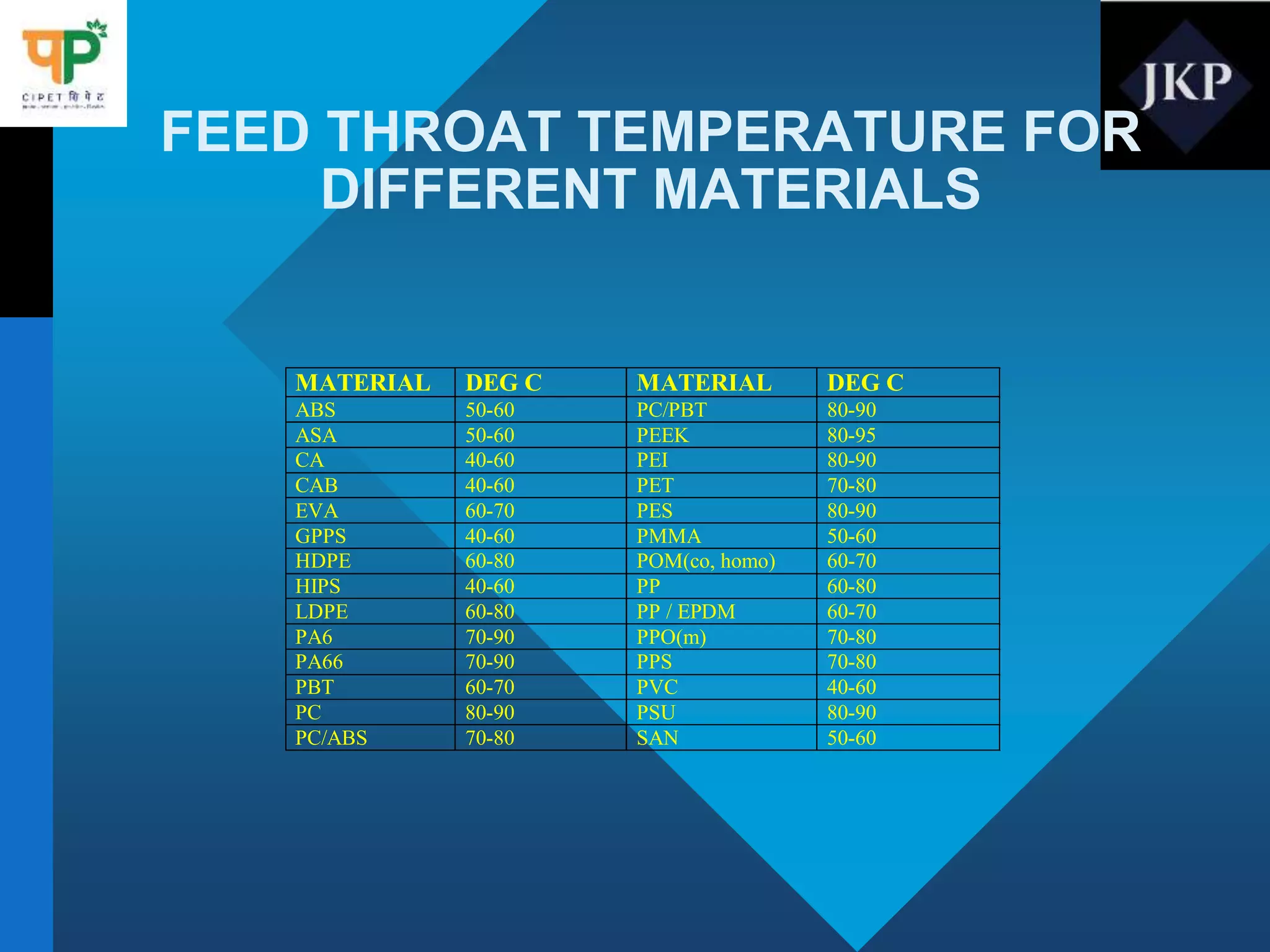

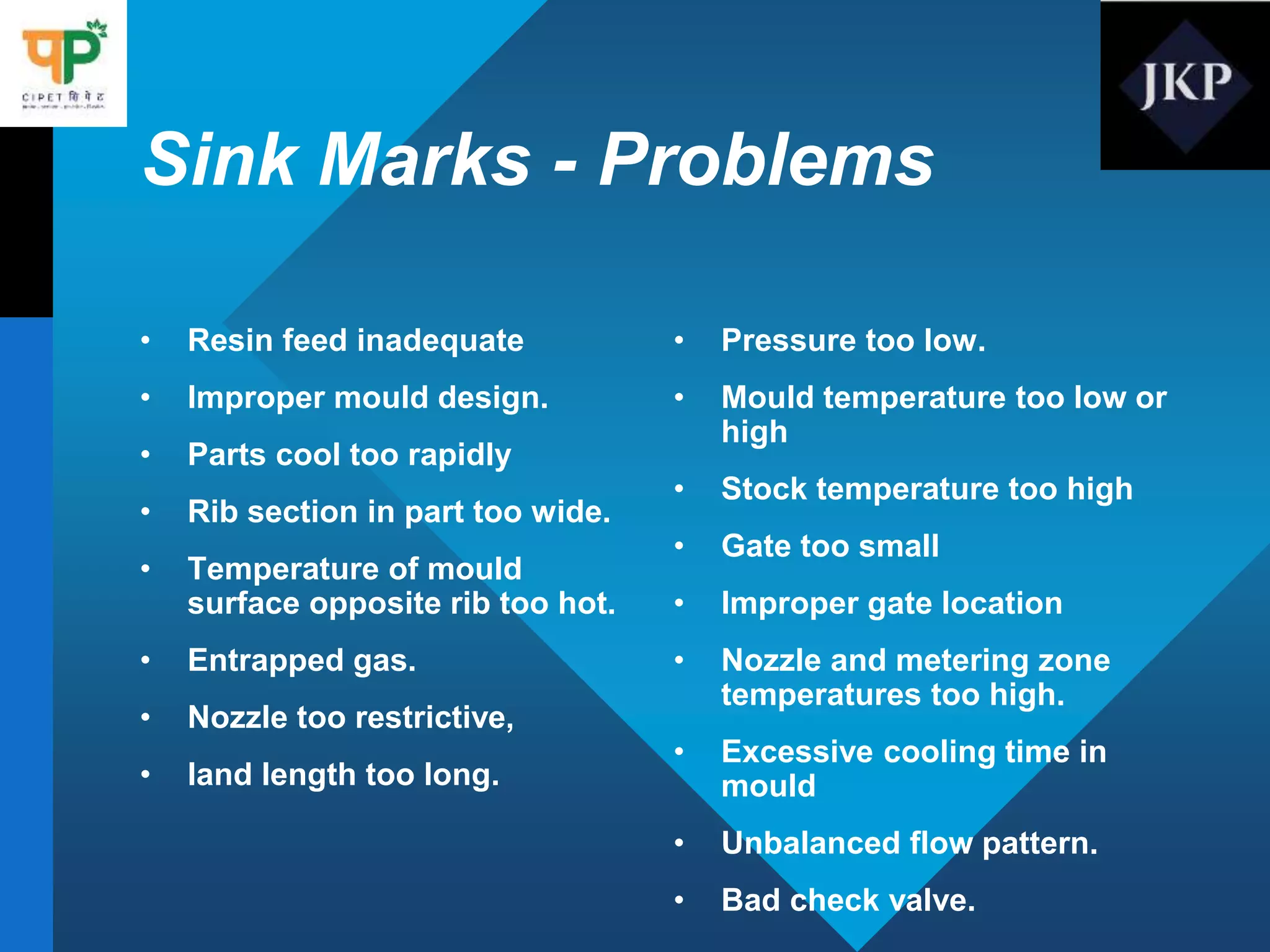

This document provides troubleshooting guidance for various defects that can occur in the injection moulding process. It describes defects such as short shots, flash, sink marks, jetting, blush marks, burn marks, and others. For each defect, it explains the possible causes and recommends checks or adjustments that can be made to the injection speed, temperatures, pressures, venting, gate size and location, and other processing parameters to address the defect. The overall goal is to identify the root cause of any issues rather than arbitrarily adjusting conditions.