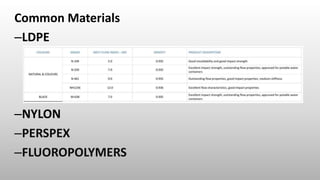

Rotational molding is a process used to create large, hollow plastic parts with uniform wall thickness. It is the only hollow parts process that can produce extremely large parts. The material is heated and rotated inside a mold to distribute it evenly. This allows for flexible designs by combining parts into one. Advantages include low-cost tooling, stress-free parts, and uniform thickness. However, cycles times are very long, ranging from 8-40 minutes. Also, only certain materials can be used and warping may occur without precise cooling. Competing processes like blow molding and injection molding have shorter cycles but cannot produce parts as large. Future developments include new materials, automation, and adding internal cooling.