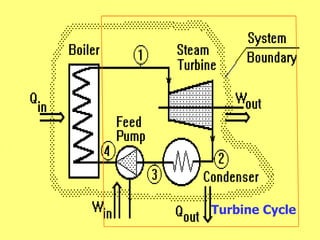

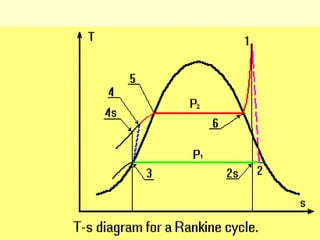

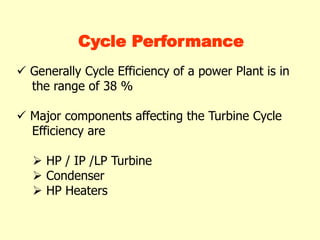

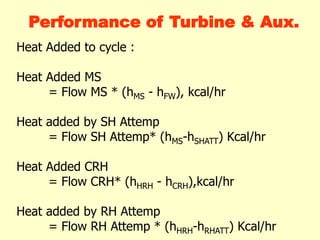

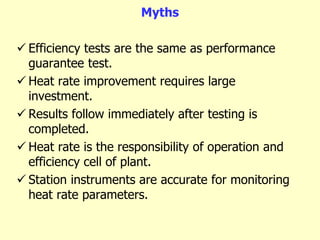

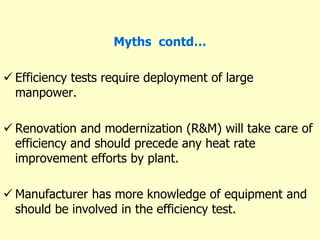

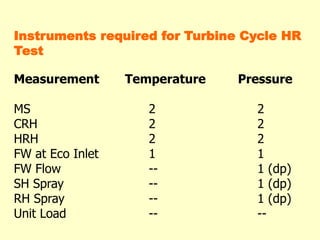

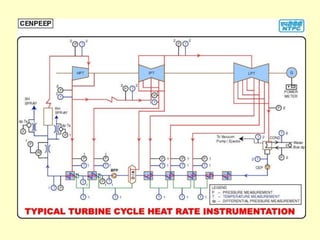

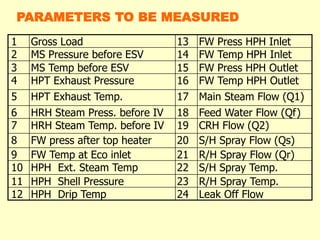

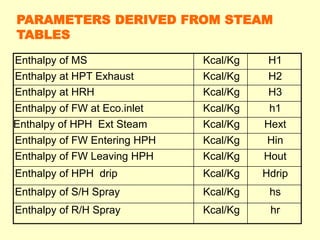

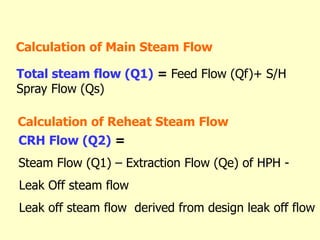

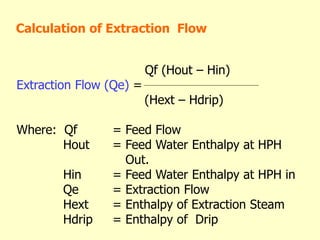

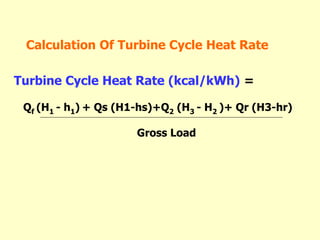

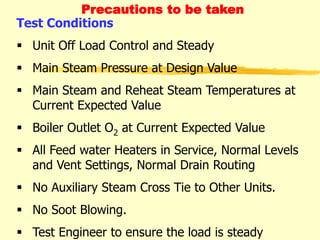

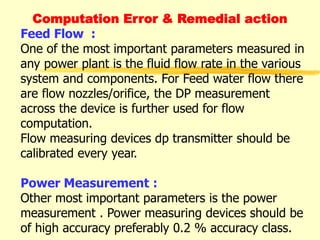

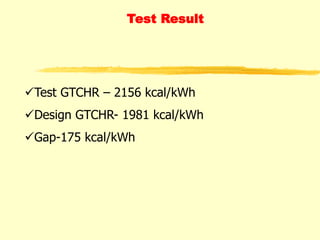

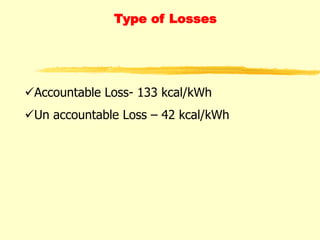

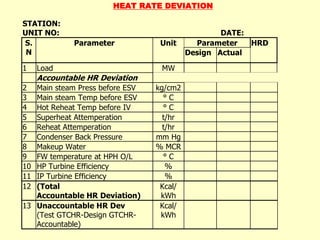

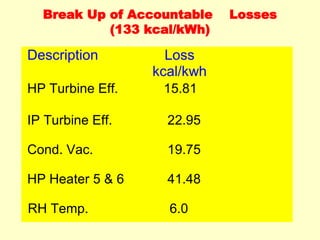

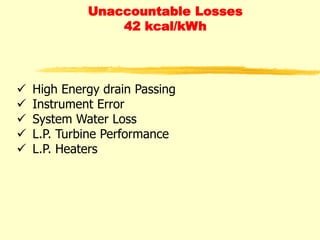

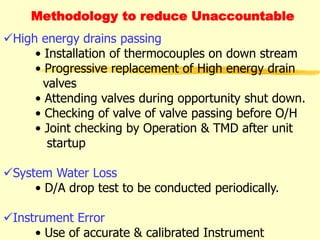

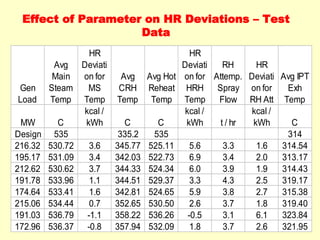

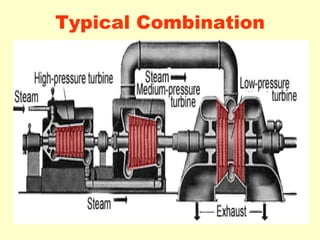

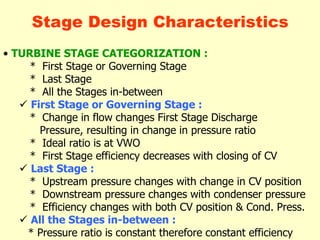

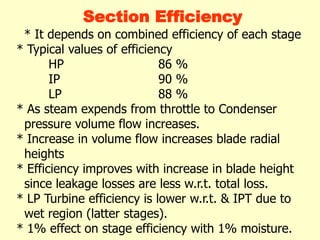

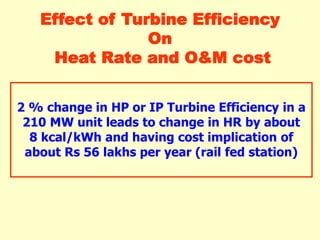

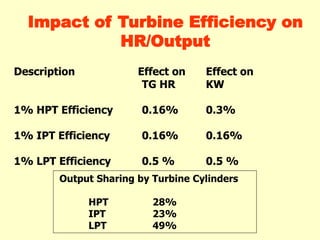

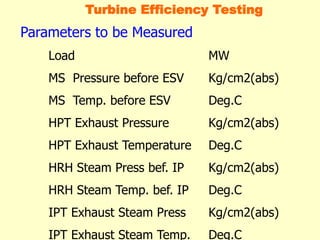

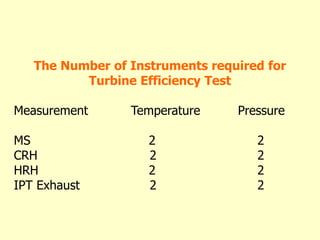

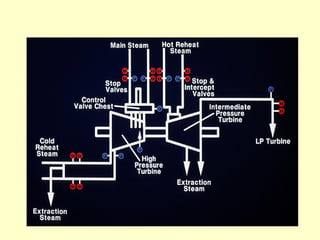

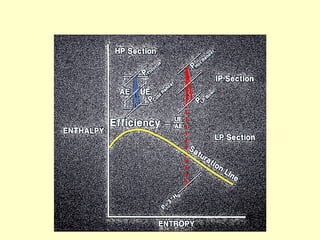

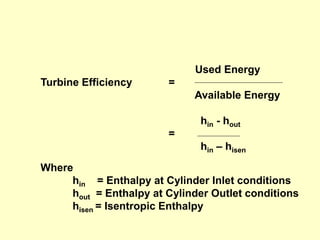

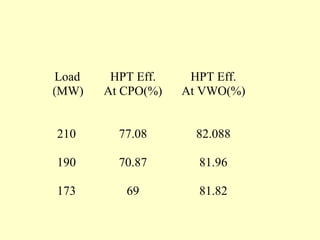

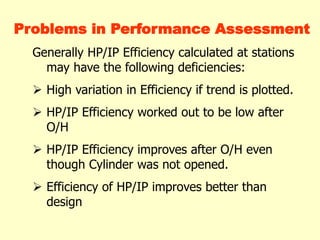

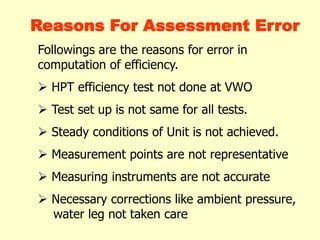

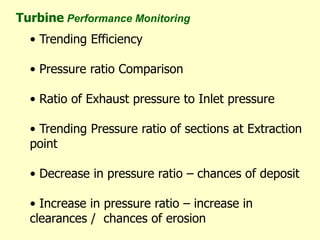

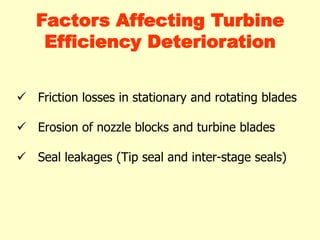

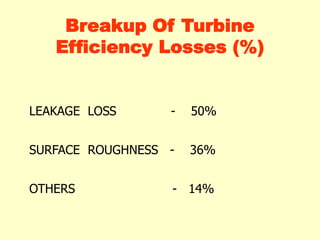

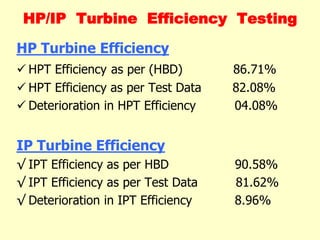

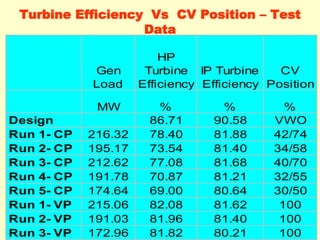

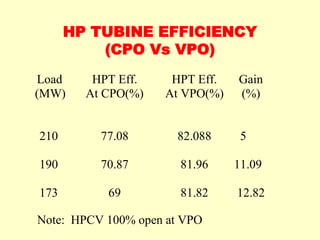

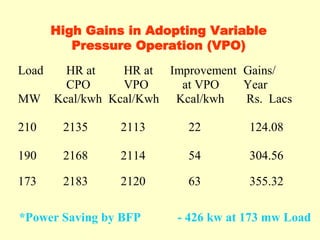

The document discusses turbine performance and efficiency in power plants, focusing on cycle efficiency and heat rate calculations. It details the main components that affect turbine cycle efficiency and addresses common myths related to efficiency testing. Additionally, it outlines the methodology for measuring turbine parameters and highlights the impact of turbine efficiency on heat rates and operating costs.