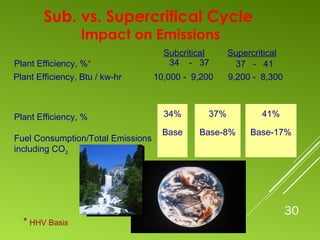

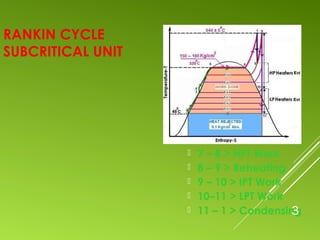

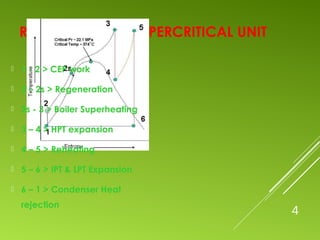

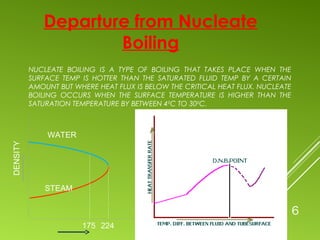

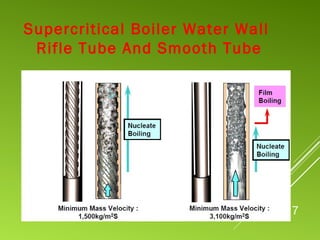

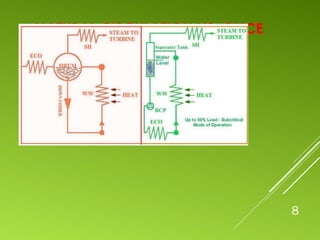

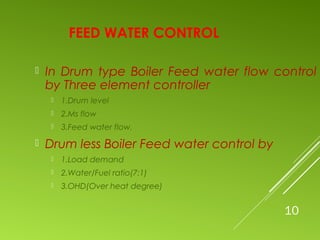

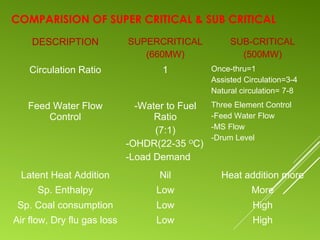

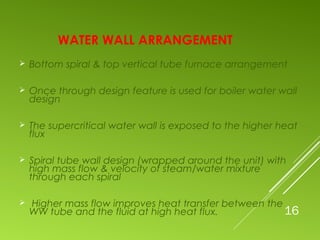

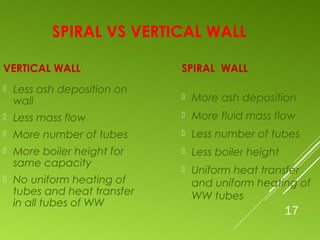

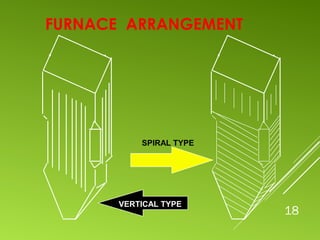

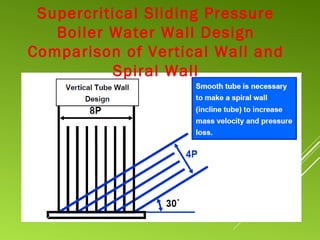

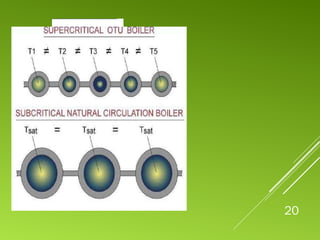

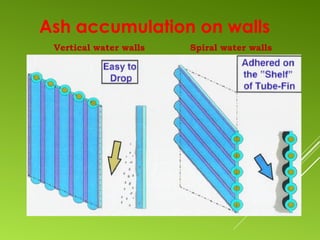

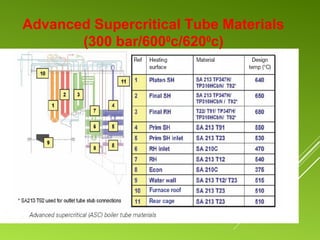

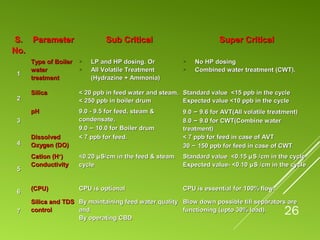

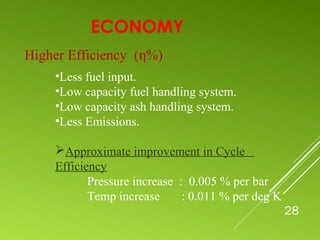

The document discusses the principles and advantages of supercritical boiler technology, highlighting its operational efficiency, lower fuel consumption, and reduced emissions compared to subcritical systems. Key differences between supercritical and subcritical cycles, such as water circulation, material requirements, and heat transfer mechanisms are outlined. Additionally, it addresses challenges in supercritical technology, such as stringent water chemistry control and maintenance difficulties.

![29

INCREASE OF CYCLE EFFICIENCY DUE TO

STEAM PARAMETERS

300

241

175 538 / 538

538 / 566

566 / 566

580 / 600

600 / 620

6,77

5,79

3,74

5,74

4,81

2,76

4,26

3,44

1,47

3,37

2,64

0,75

2,42

1,78

0

0

1

2

3

4

5

6

7

8

9

10

HP / RH outlet temperature [deg. C]Pressure [bar]

Increase of efficiency [%]](https://image.slidesharecdn.com/super-criticalboiler-160309140412/85/Super-critical-boiler-29-320.jpg)