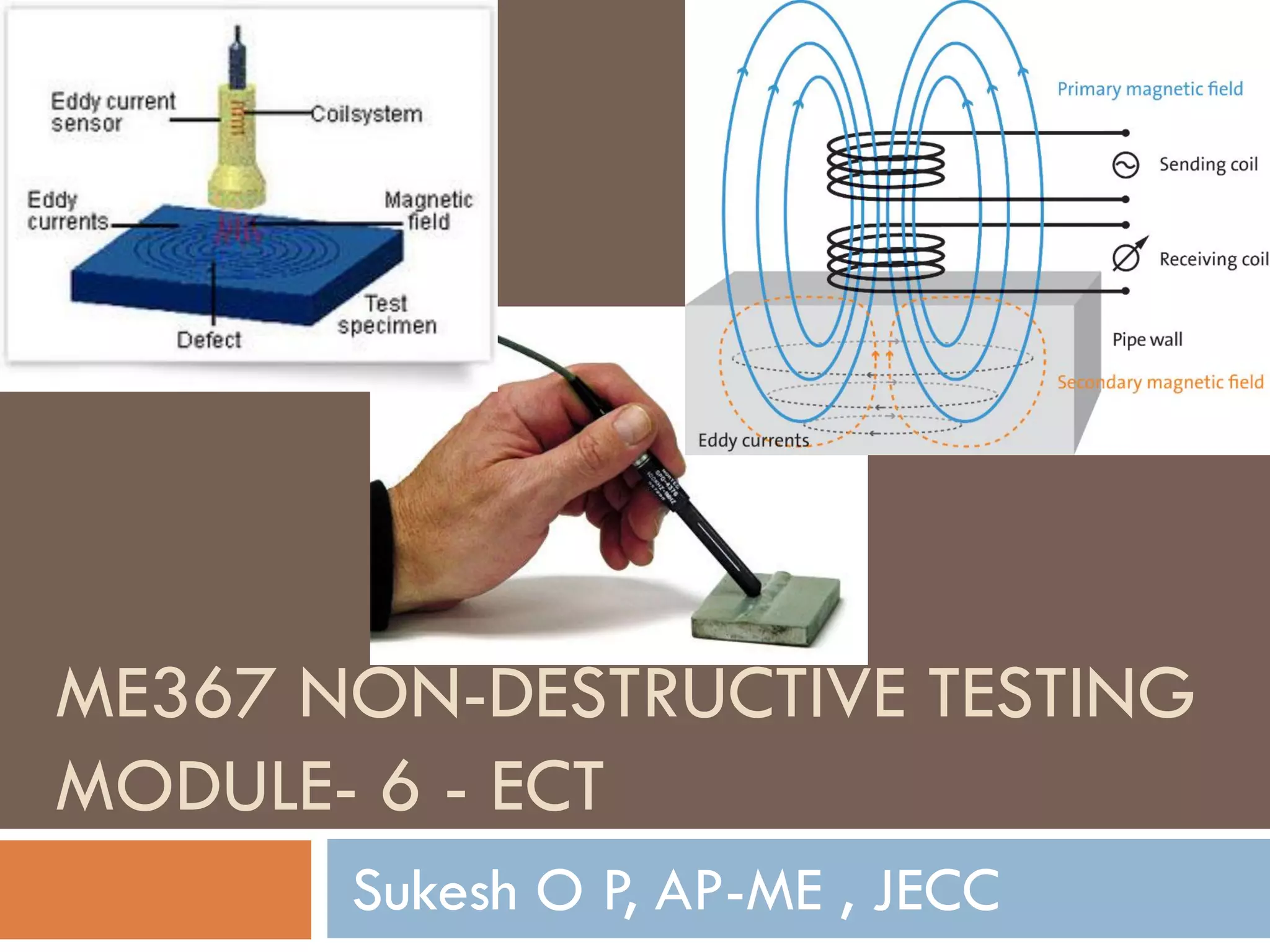

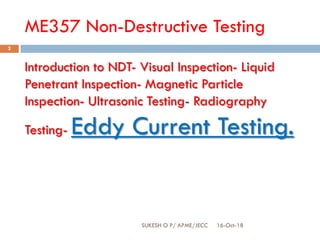

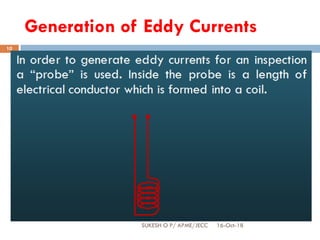

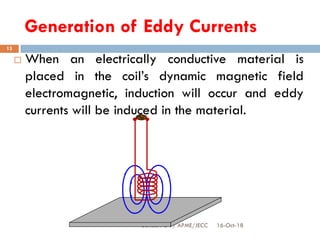

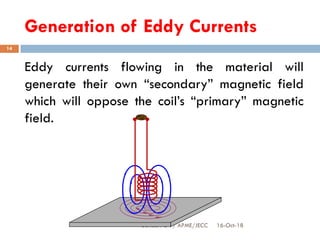

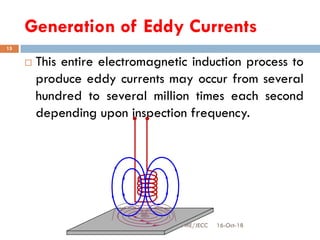

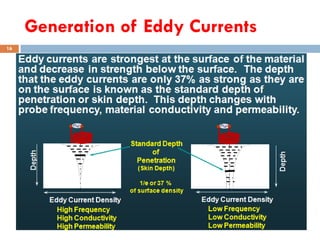

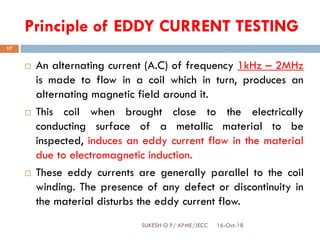

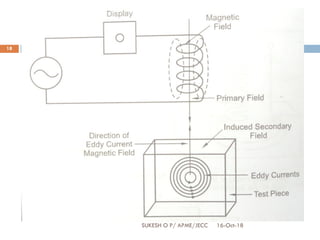

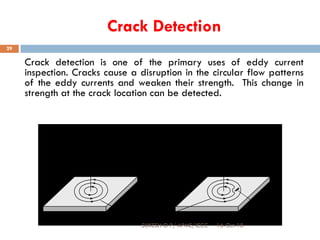

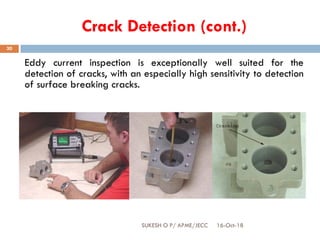

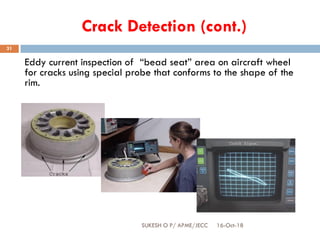

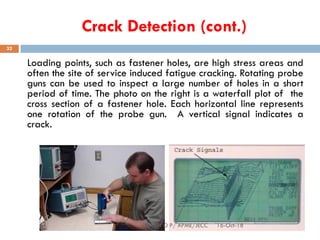

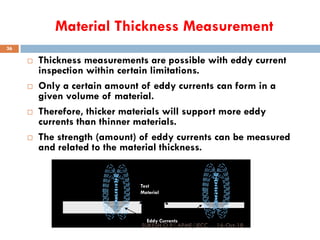

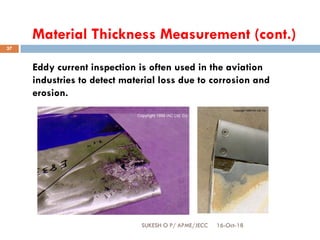

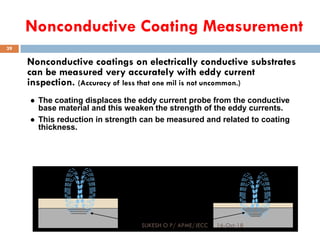

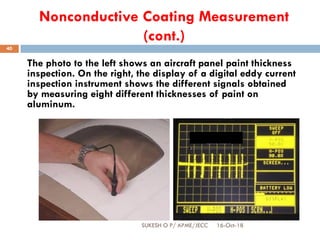

Eddy current testing (ECT) uses electromagnetic induction to detect flaws in conductive materials. It works by inducing eddy currents in a test material using a coil producing an alternating magnetic field. Any discontinuities in the material like cracks will disrupt the eddy current flow and can be detected. ECT is used for applications like conducting inspections of heat exchanger tubes and aircraft components to detect cracks, measuring material thickness, and identifying material properties. It offers benefits like being able to inspect complex shapes and detect surface-breaking flaws with portable equipment and minimal part preparation.