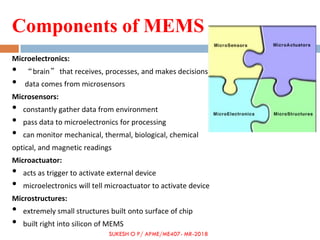

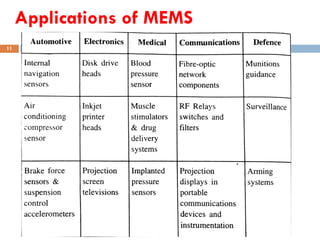

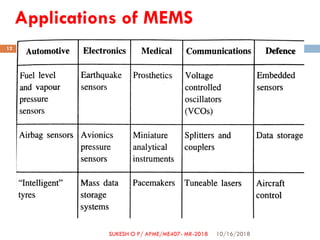

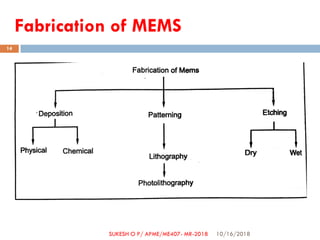

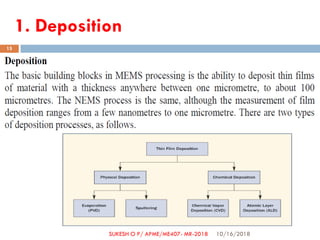

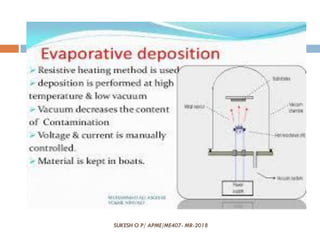

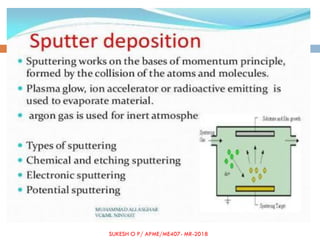

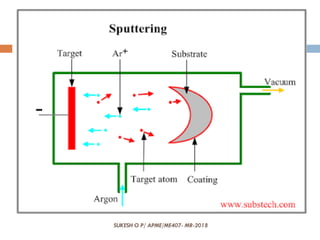

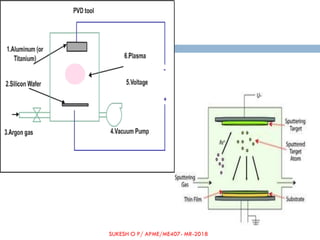

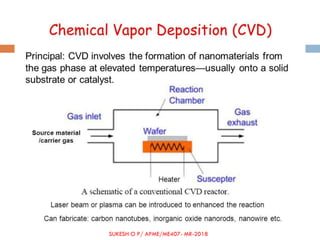

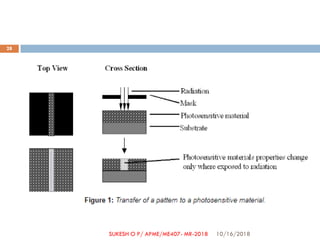

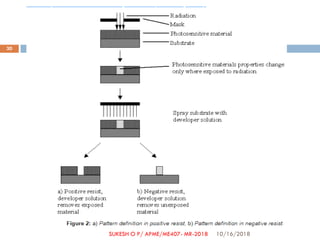

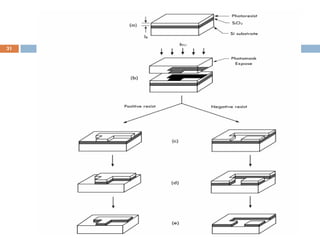

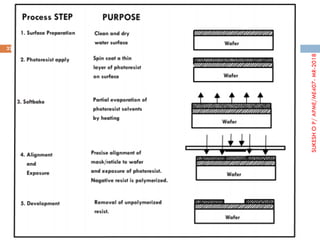

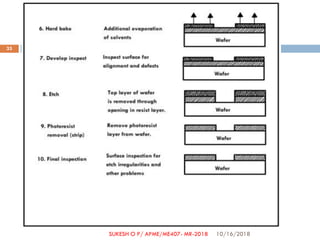

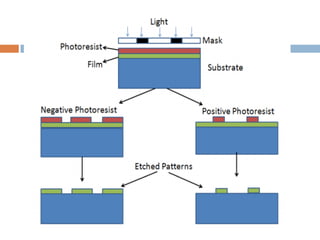

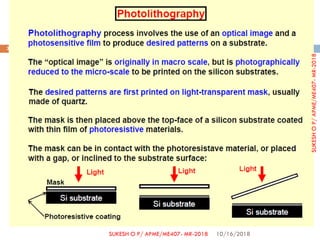

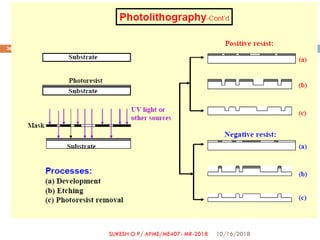

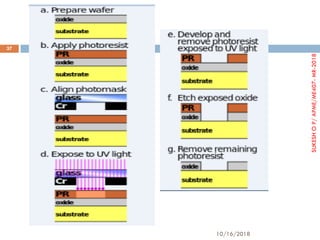

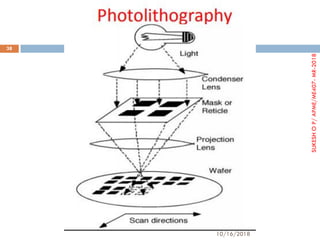

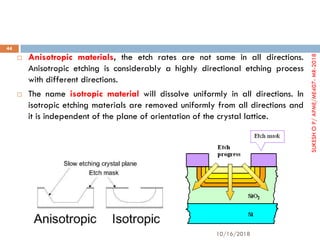

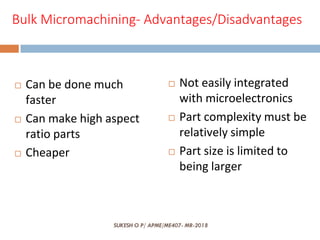

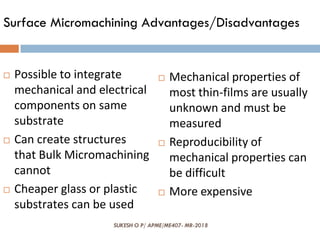

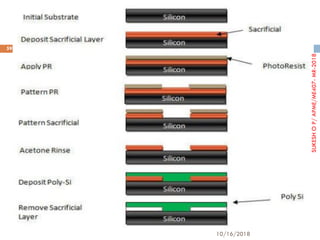

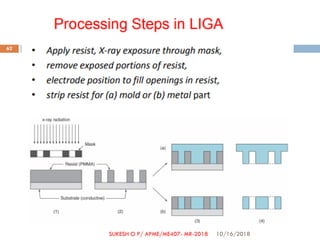

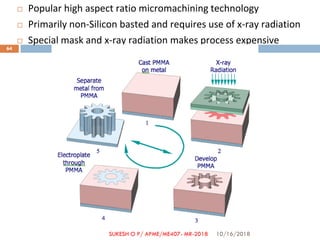

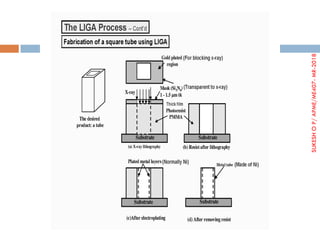

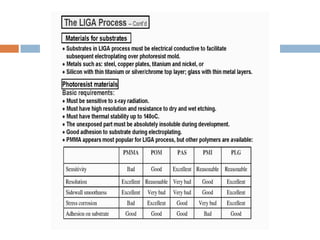

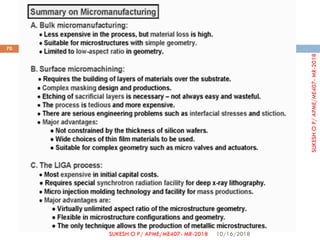

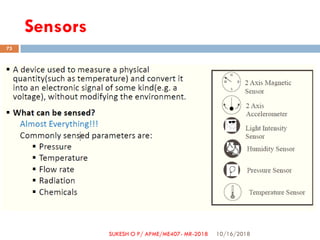

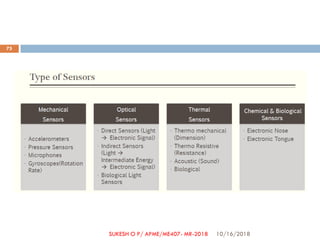

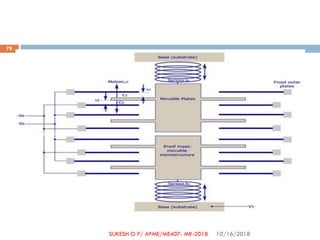

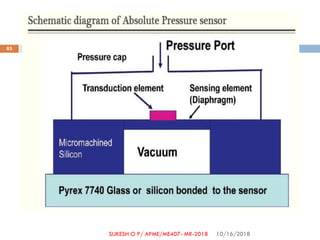

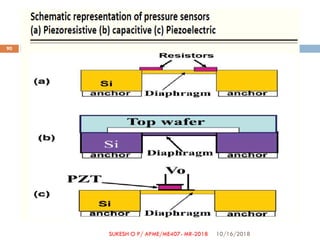

This document discusses the course ME407 Mechatronics. The course objectives are to introduce various sensors used in machines and robots, study MEMS pressure and inertial sensors, and develop hydraulic/pneumatic circuits and PLC programs. The expected outcomes are for students to understand mechanical systems in mechatronics and integrate mechanical, electronic, control and computer engineering in design. The syllabus covers introduction to mechatronics, sensors, actuators, MEMS, and case studies. Fabrication of MEMS is also discussed, including deposition, patterning using photolithography, and etching processes.