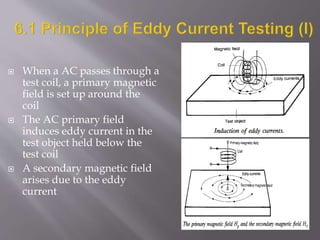

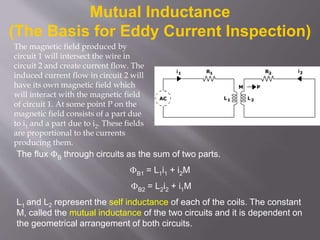

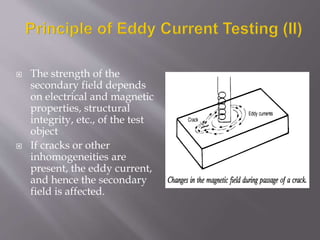

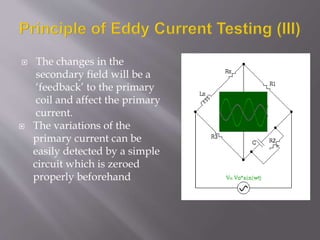

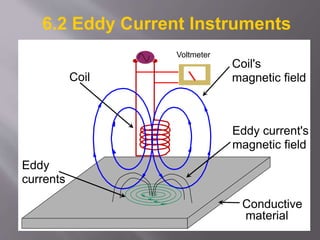

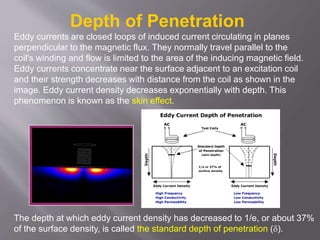

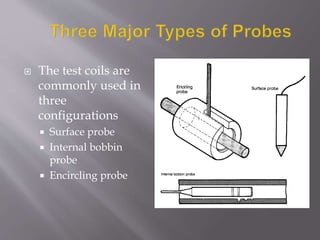

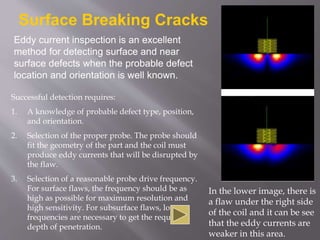

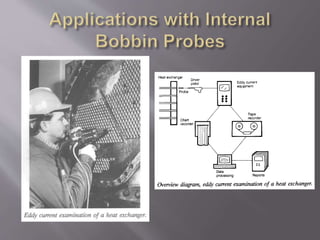

Eddy current testing uses a test coil to generate eddy currents in a conductive material. Interruptions in the eddy currents caused by defects can be detected. It can be used to detect cracks, measure material thickness or coating thickness, and identify materials. The test coil induces eddy currents which generate a secondary magnetic field. Changes in this field from defects provide feedback to the primary coil that can be measured. It is effective for surface and near surface flaws and has advantages of being portable, non-contact, and suitable for complex shapes. Limitations include being limited to conductive materials and limited penetration depth.