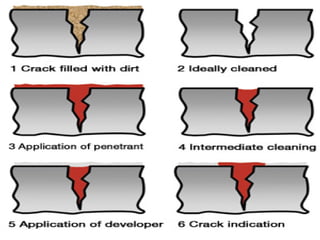

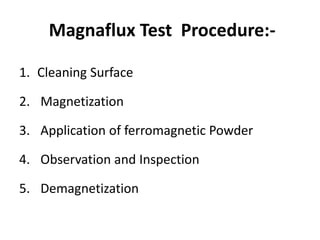

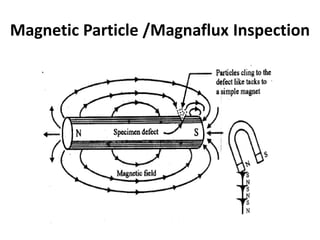

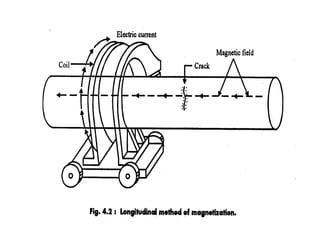

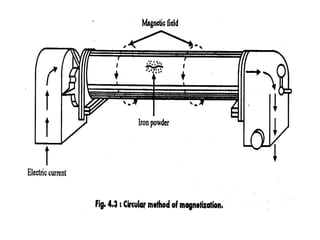

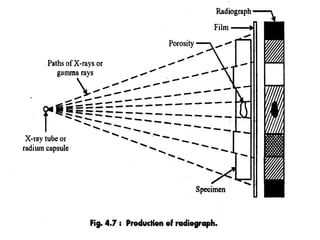

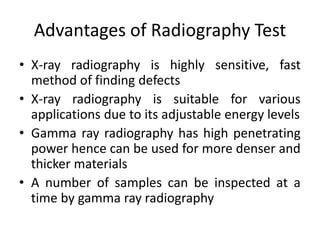

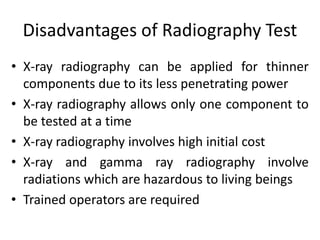

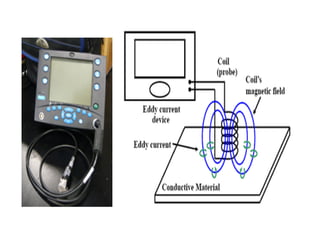

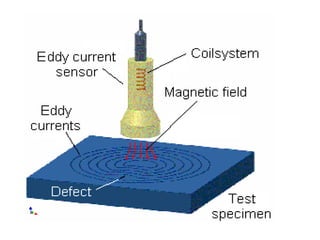

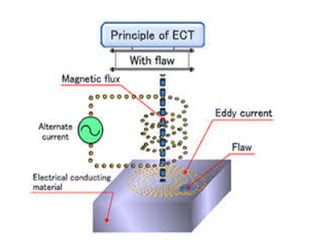

Nondestructive testing (NDT) is a group of analysis techniques that evaluate materials without causing damage, saving time and money in product evaluation. Common methods include eddy-current, magnetic-particle, dye penetrant, radiographic, ultrasonic, and visual testing, each with unique procedures and applications across various engineering fields. The techniques are crucial for detecting flaws, ensuring component integrity, and preventing costly failures.