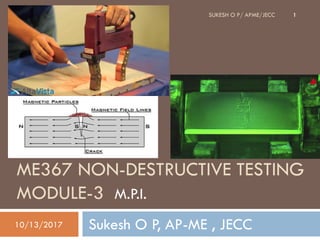

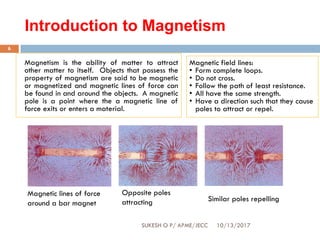

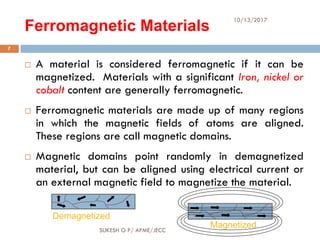

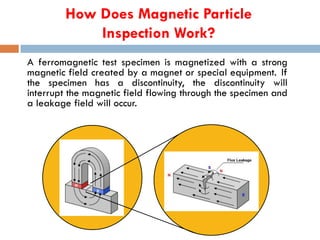

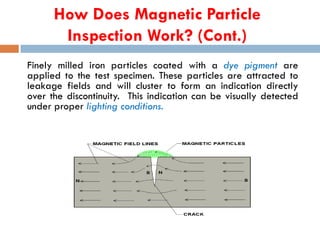

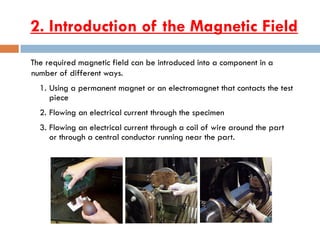

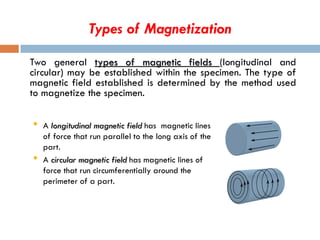

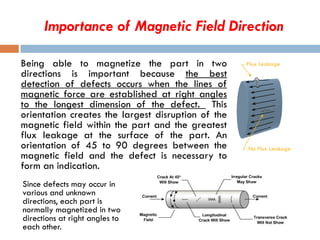

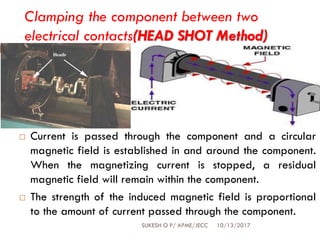

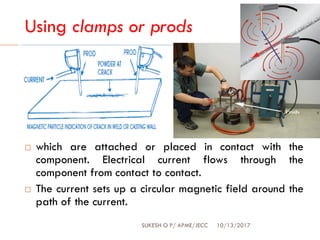

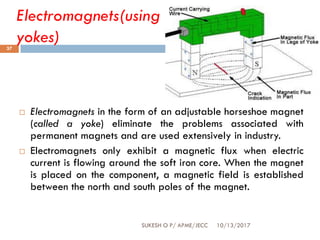

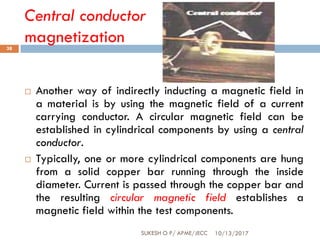

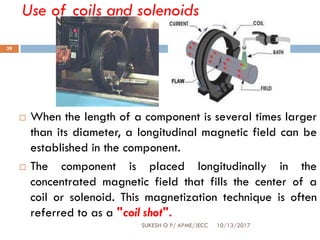

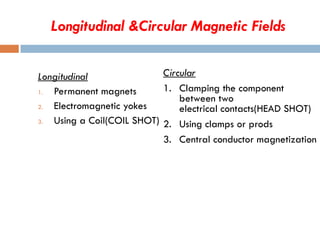

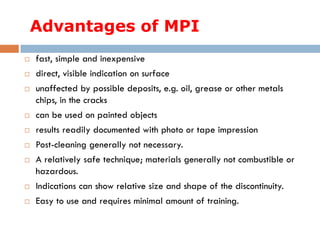

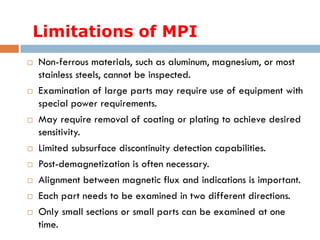

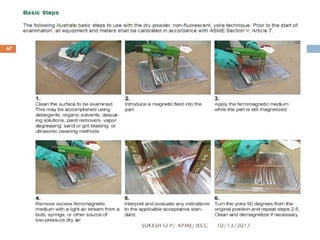

The document discusses Magnetic Particle Inspection (MPI), including the principles, methods, and basic procedure. MPI uses magnetic fields to detect discontinuities in ferromagnetic materials. A component is magnetized, then magnetic particles are applied to reveal defects that interrupt magnetic field flow. Methods to introduce magnetic fields include direct and indirect techniques using things like electromagnets, coils, and magnetic yokes. Interpretation of particle indications is required to identify relevant defects.