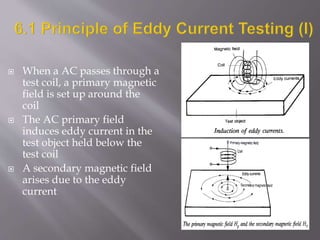

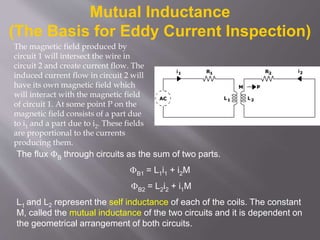

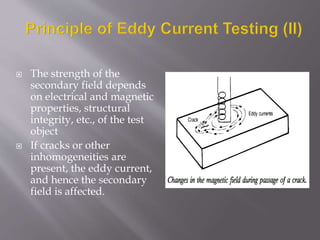

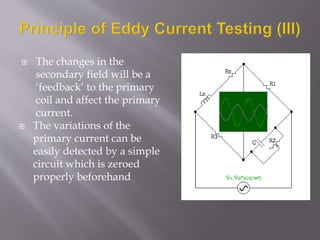

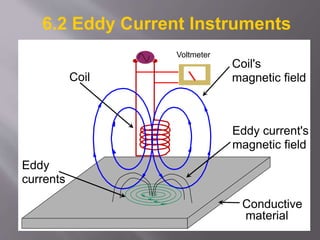

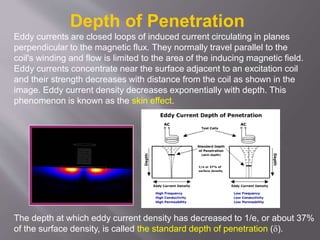

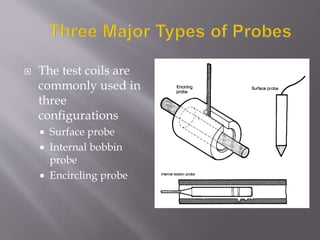

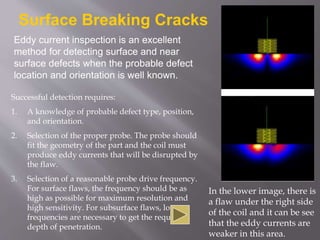

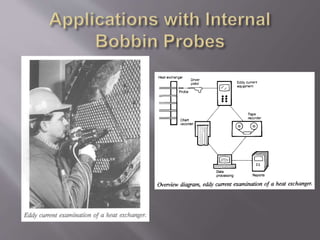

Eddy current testing uses a coil to generate an alternating magnetic field that induces eddy currents in a conductive test material. Interruptions in the eddy currents from defects can be detected by changes in the secondary magnetic field and fed back to the testing equipment. It is used for applications like crack detection, material thickness measurement, and coating thickness measurement due to providing immediate results on conductive materials with accessible surfaces. Limitations include being unable to inspect non-conductive materials and detect certain defect orientations.