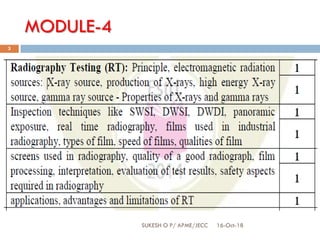

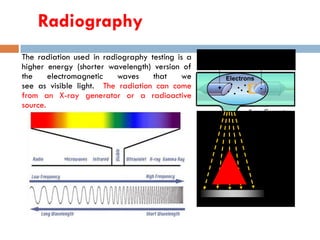

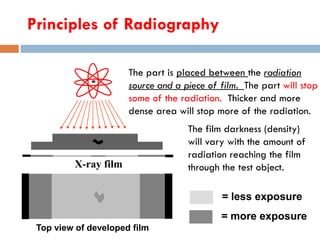

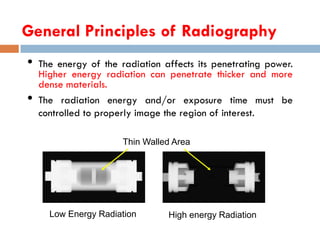

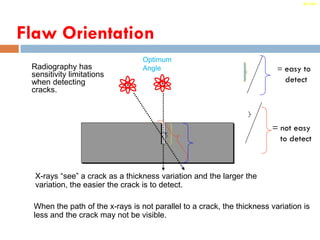

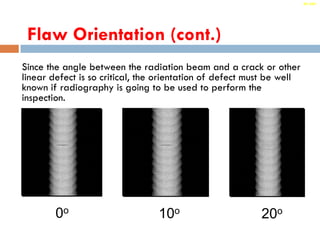

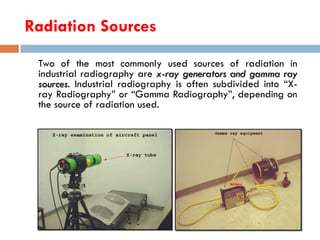

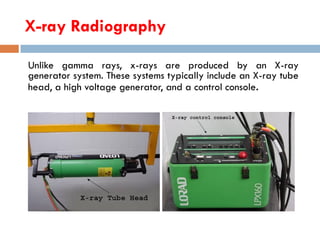

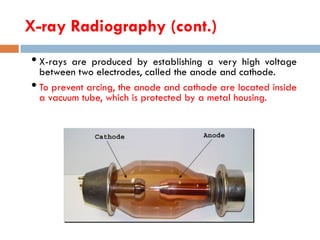

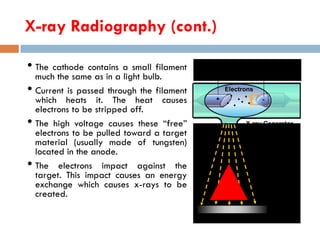

This document discusses radiographic testing (RT), which uses x-rays or gamma rays to examine internal structures without destroying the test object. It describes how x-rays and gamma rays are produced and used to penetrate test objects. Images are captured on film, with denser areas appearing darker. RT can detect surface and subsurface flaws and provide permanent inspection records. Limitations include difficulty detecting cracks oriented obliquely to the radiation beam.