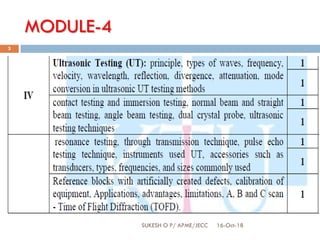

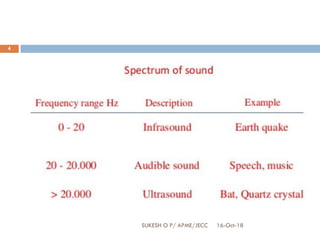

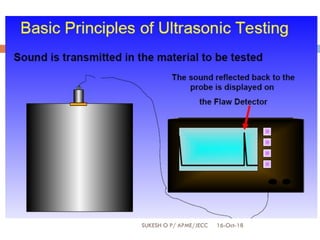

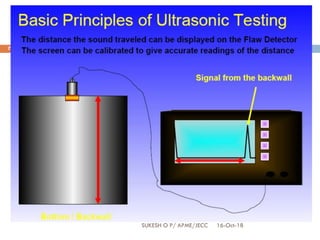

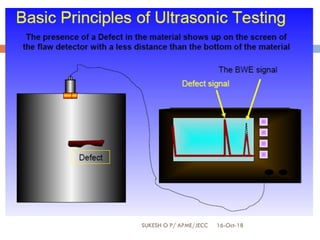

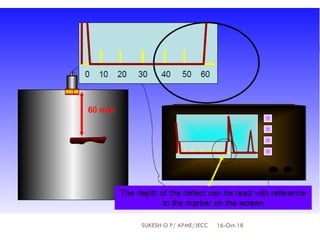

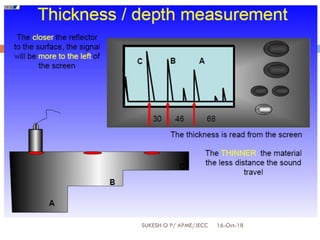

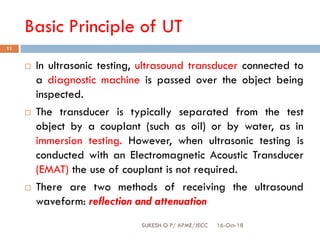

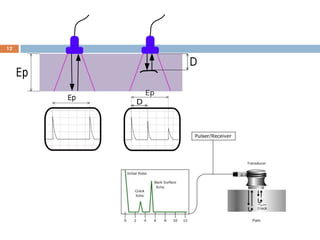

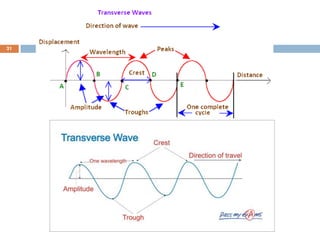

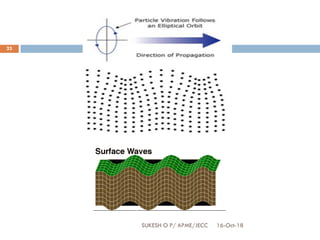

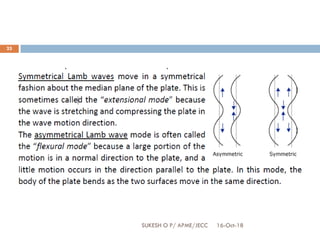

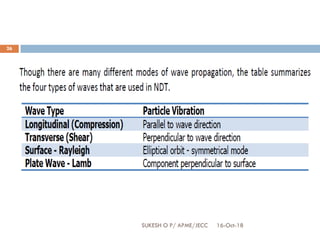

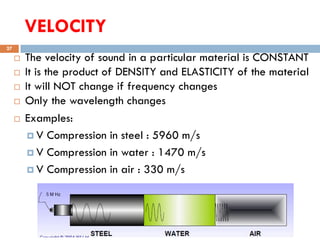

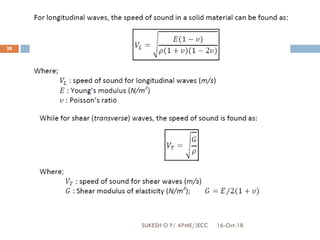

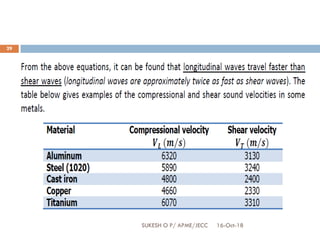

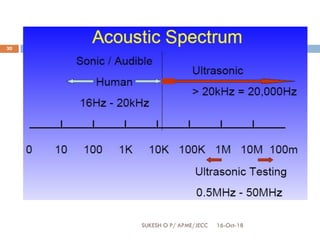

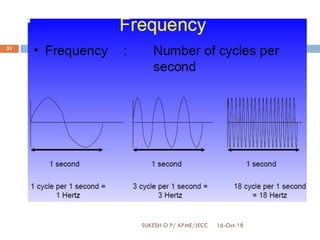

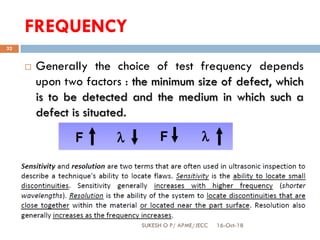

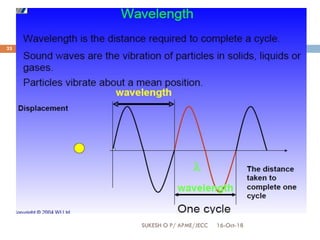

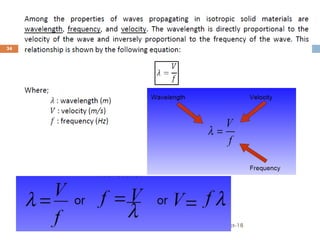

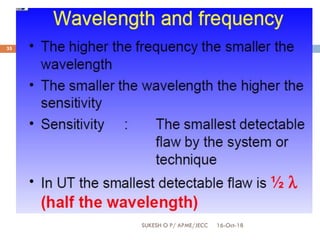

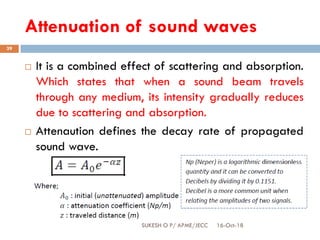

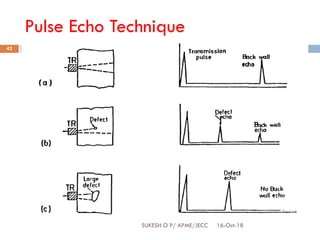

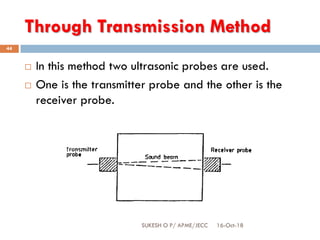

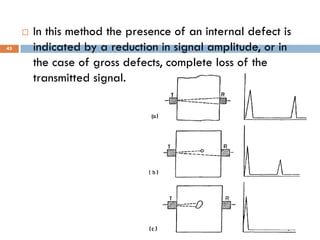

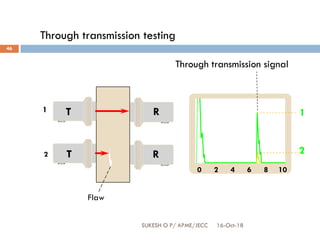

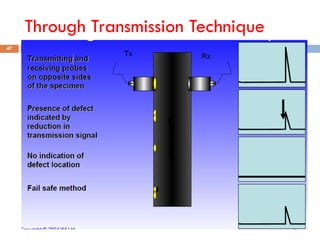

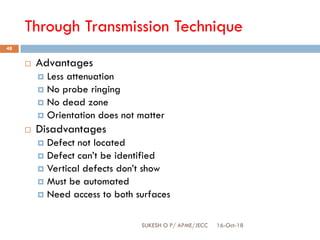

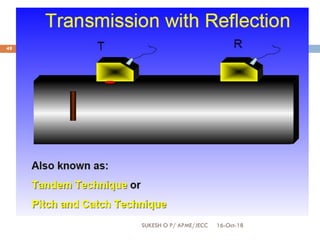

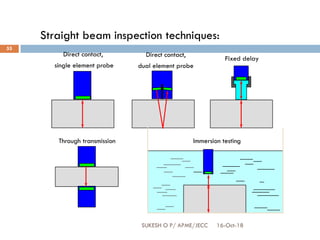

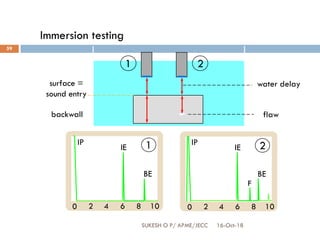

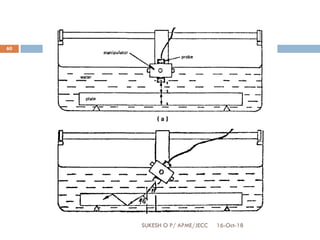

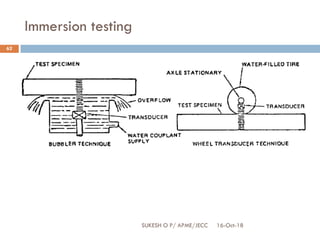

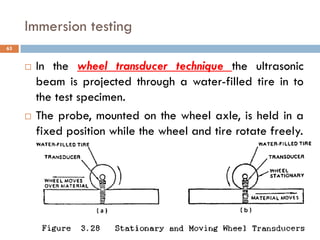

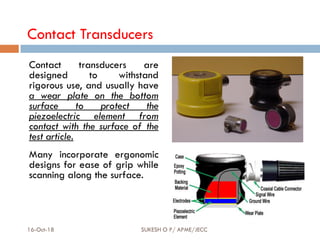

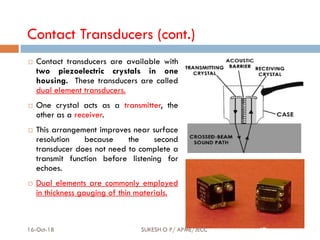

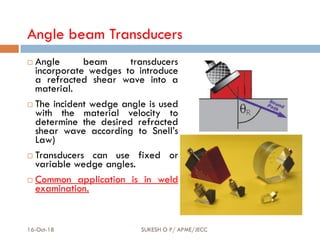

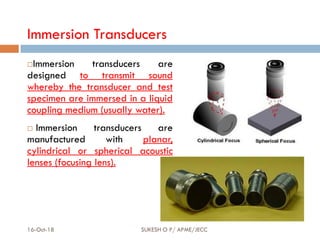

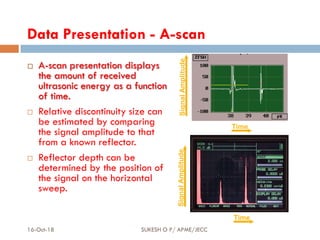

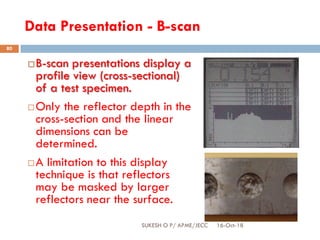

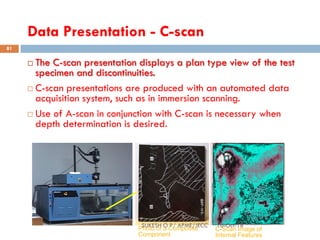

The document discusses ultrasonic testing (UT), which uses high frequency sound waves to detect surface and internal flaws in materials. It describes the basic principles of UT, including how sound waves propagate through materials and are reflected by discontinuities. The document outlines various UT techniques, such as pulse-echo, through transmission, angle beam, and immersion testing. It also covers concepts related to sound waves like velocity, frequency, attenuation, and the different modes of wave propagation.