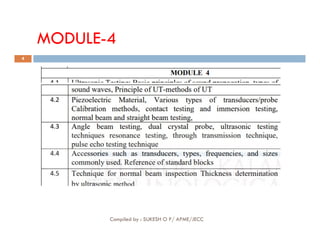

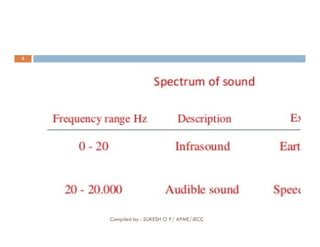

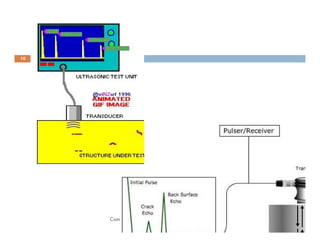

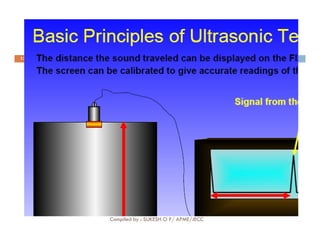

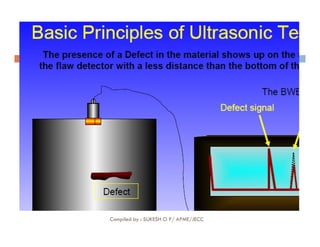

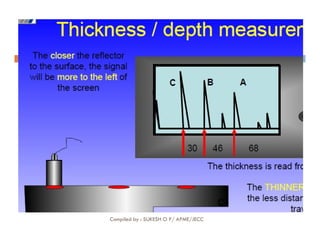

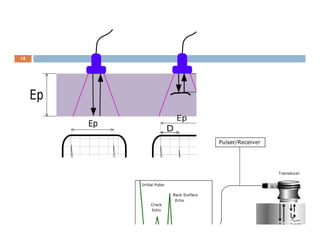

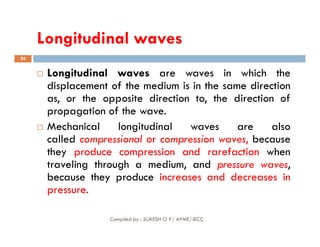

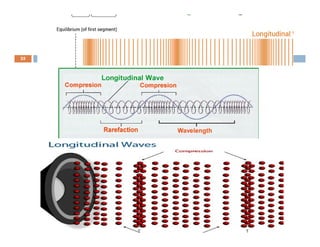

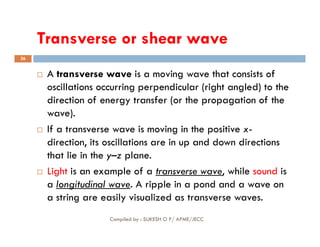

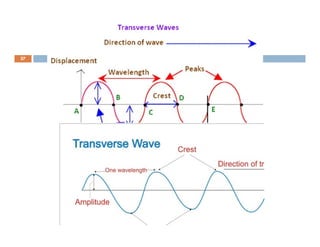

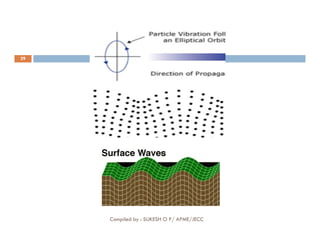

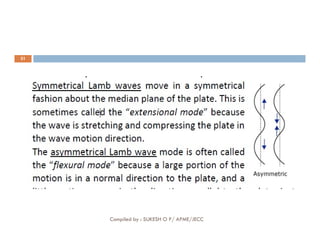

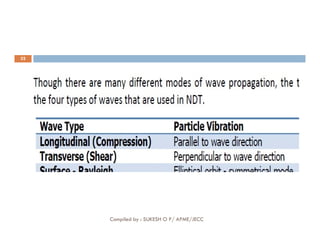

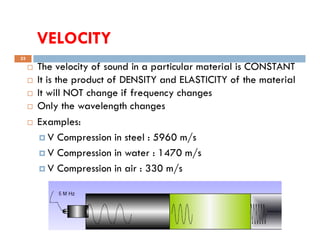

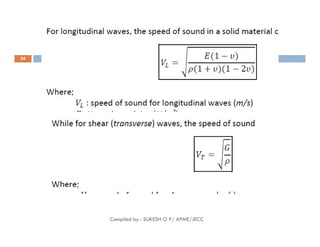

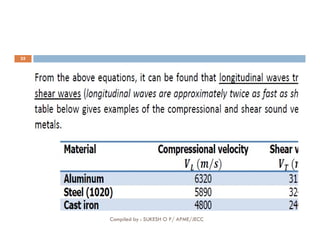

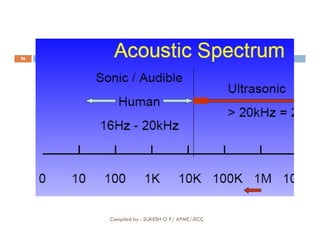

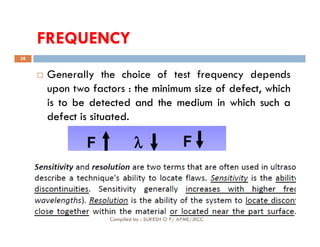

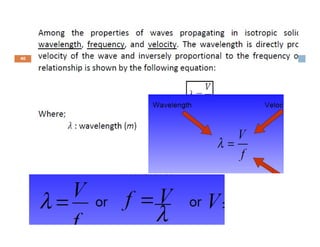

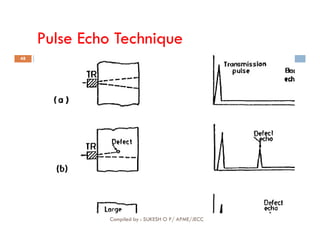

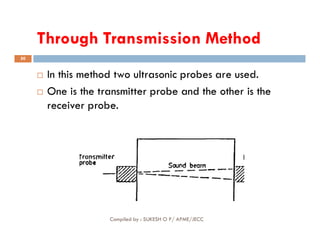

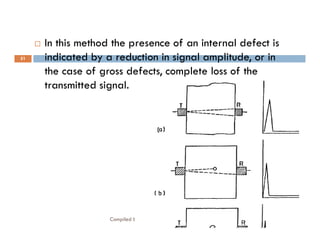

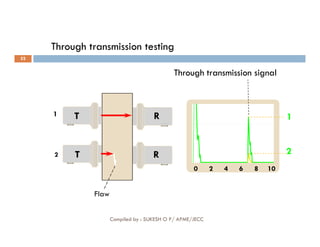

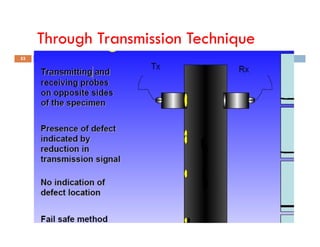

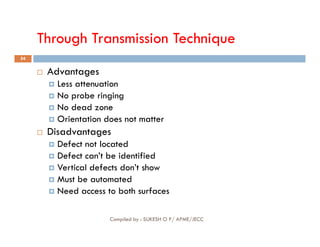

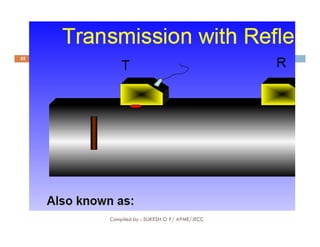

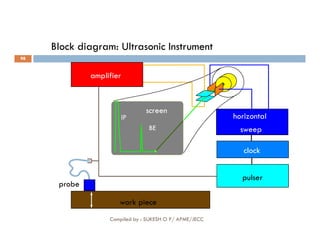

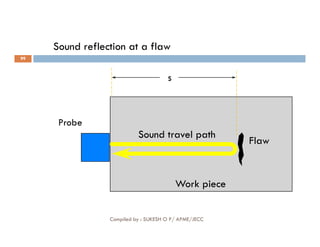

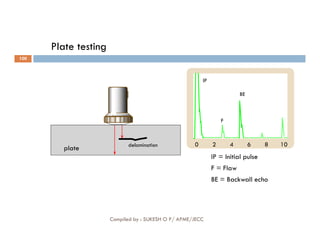

The document discusses ultrasonic testing (UT), which uses high frequency sound waves to examine materials and make measurements. UT can be used to detect internal flaws like cracks, voids, and inclusions. The three main types of sound waves are longitudinal waves, transverse waves, and surface waves. UT works by transmitting sound waves into a material and analyzing waves that reflect back from internal structures and defects.