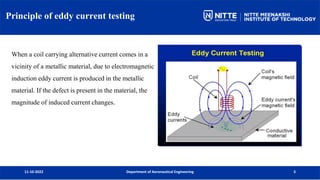

The document discusses the importance of eddy current testing as a non-destructive technique for evaluating the properties of conductive materials, particularly in the aeronautical engineering field. It highlights the advantages of this method, such as crack detection capabilities, cost-effectiveness, and application without direct contact with the material. The text also references a tragic incident where failure to utilize eddy current testing led to a significant accident, underscoring the necessity of this technology in aircraft maintenance.