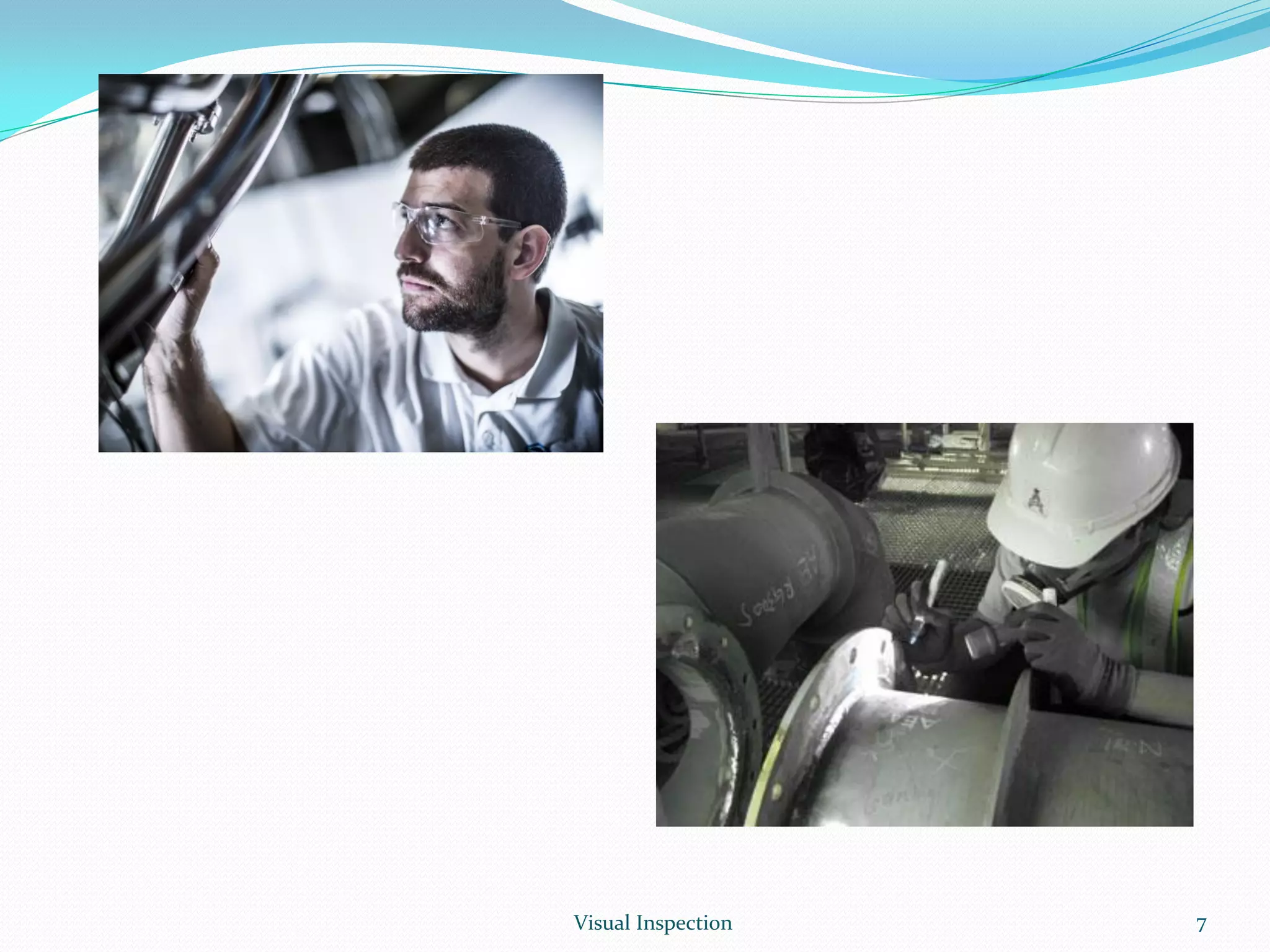

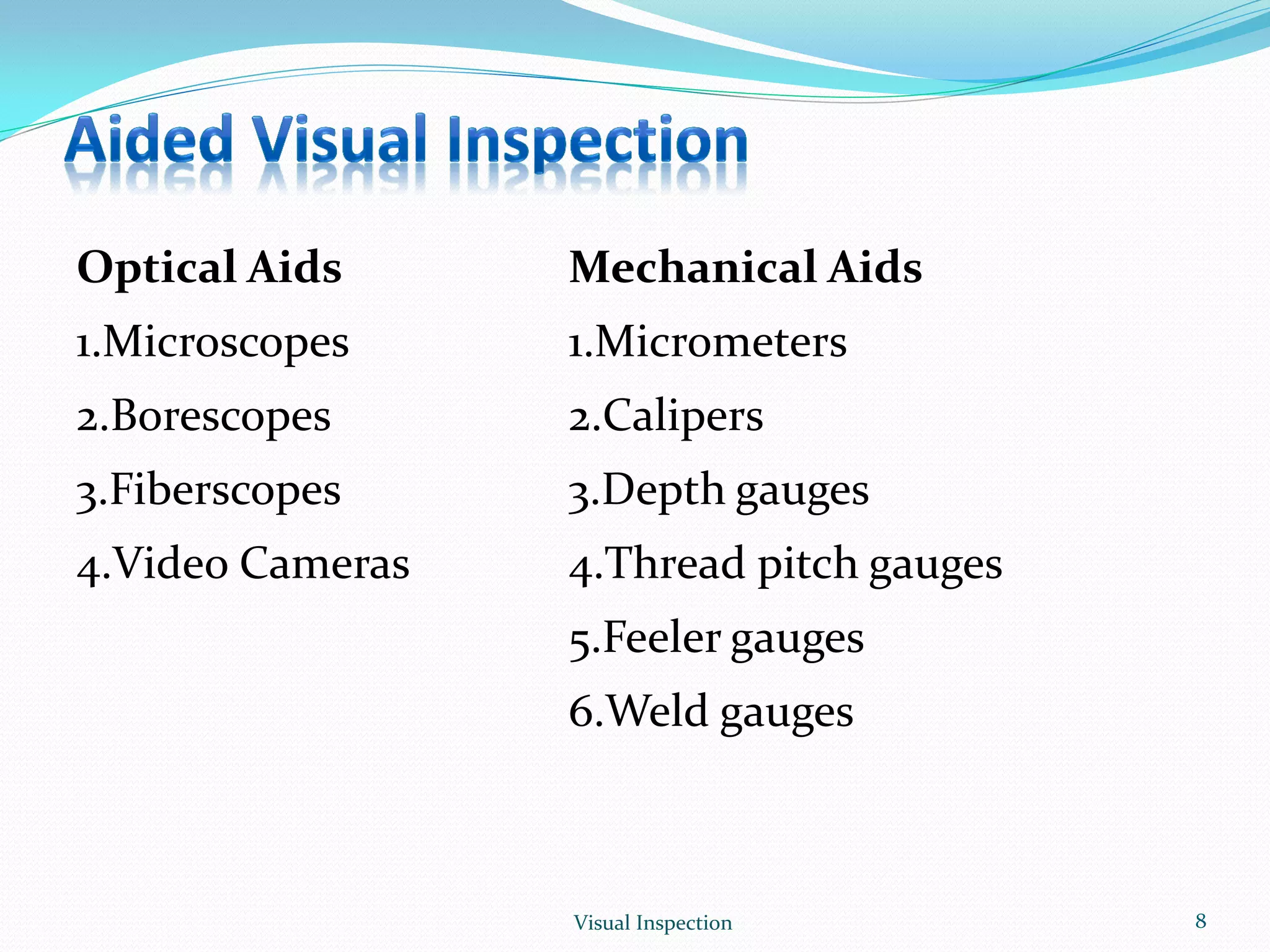

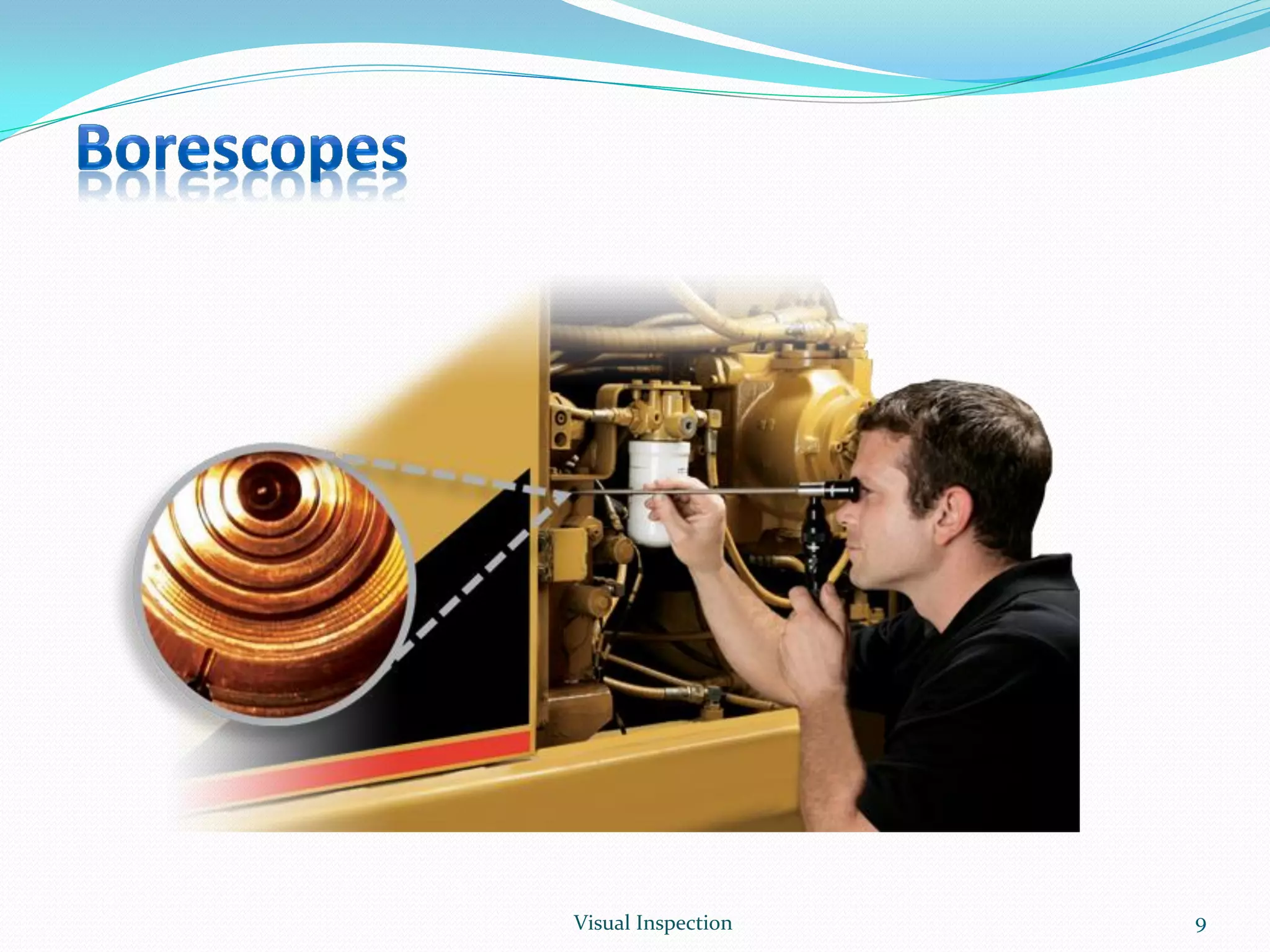

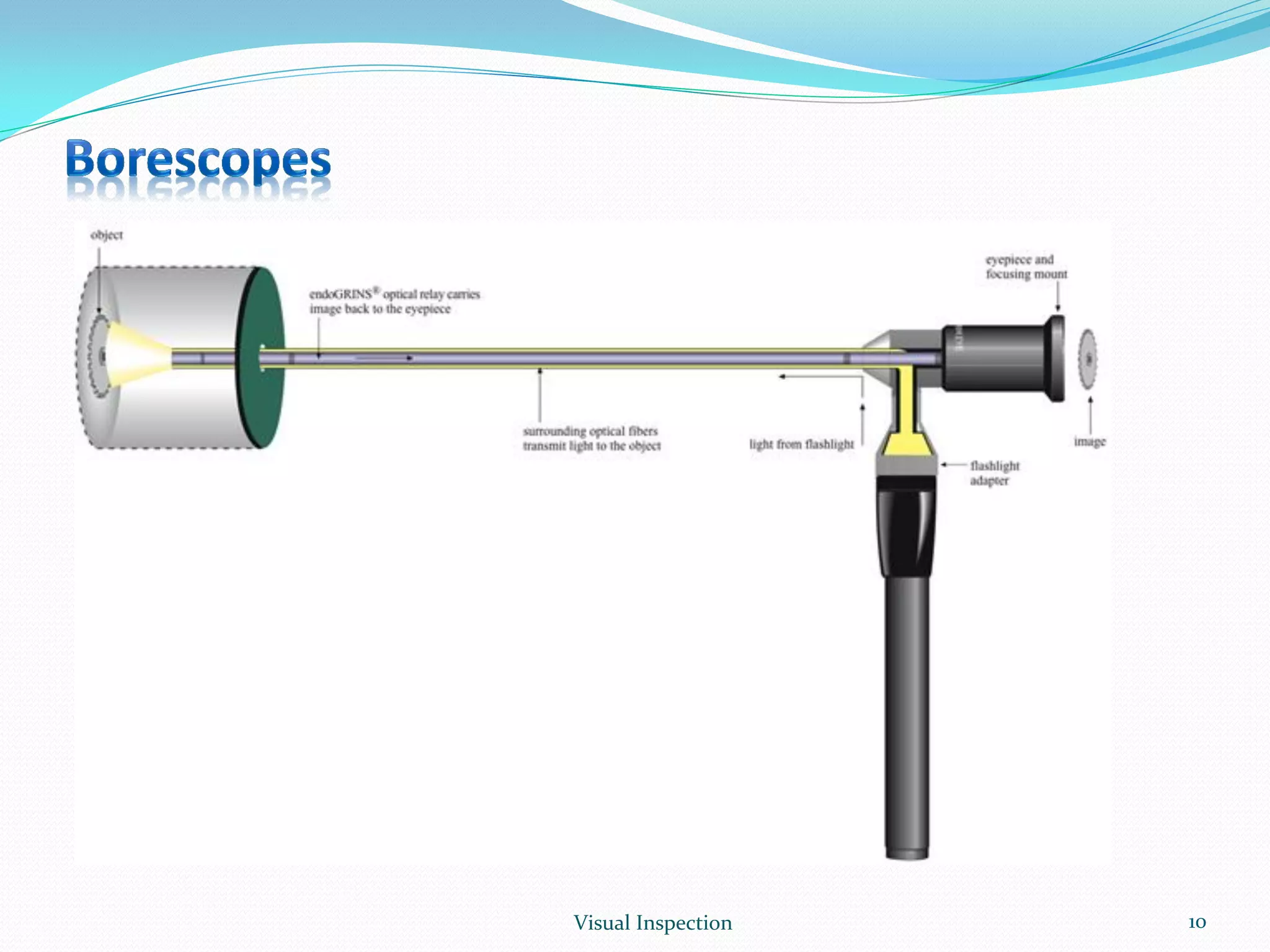

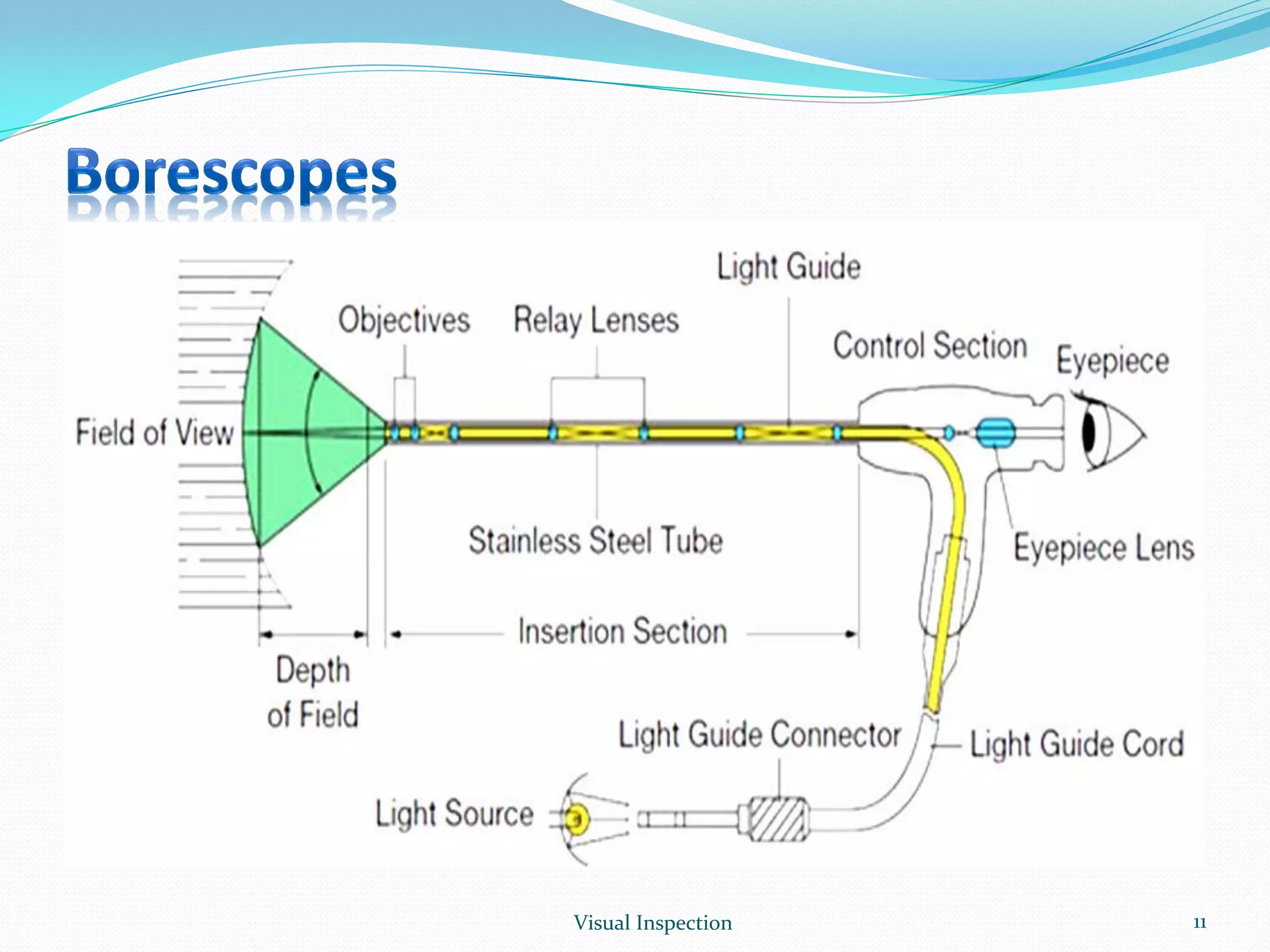

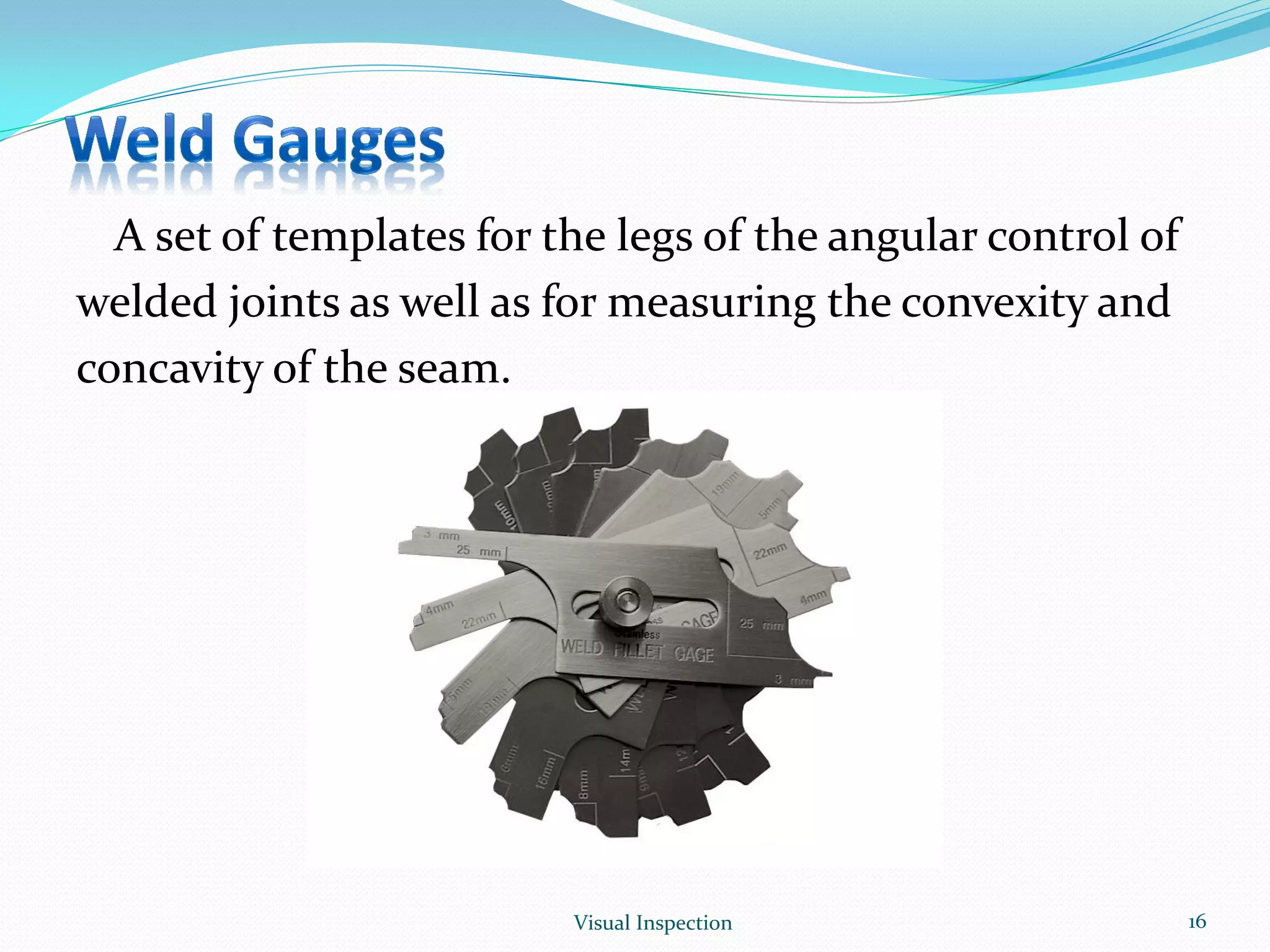

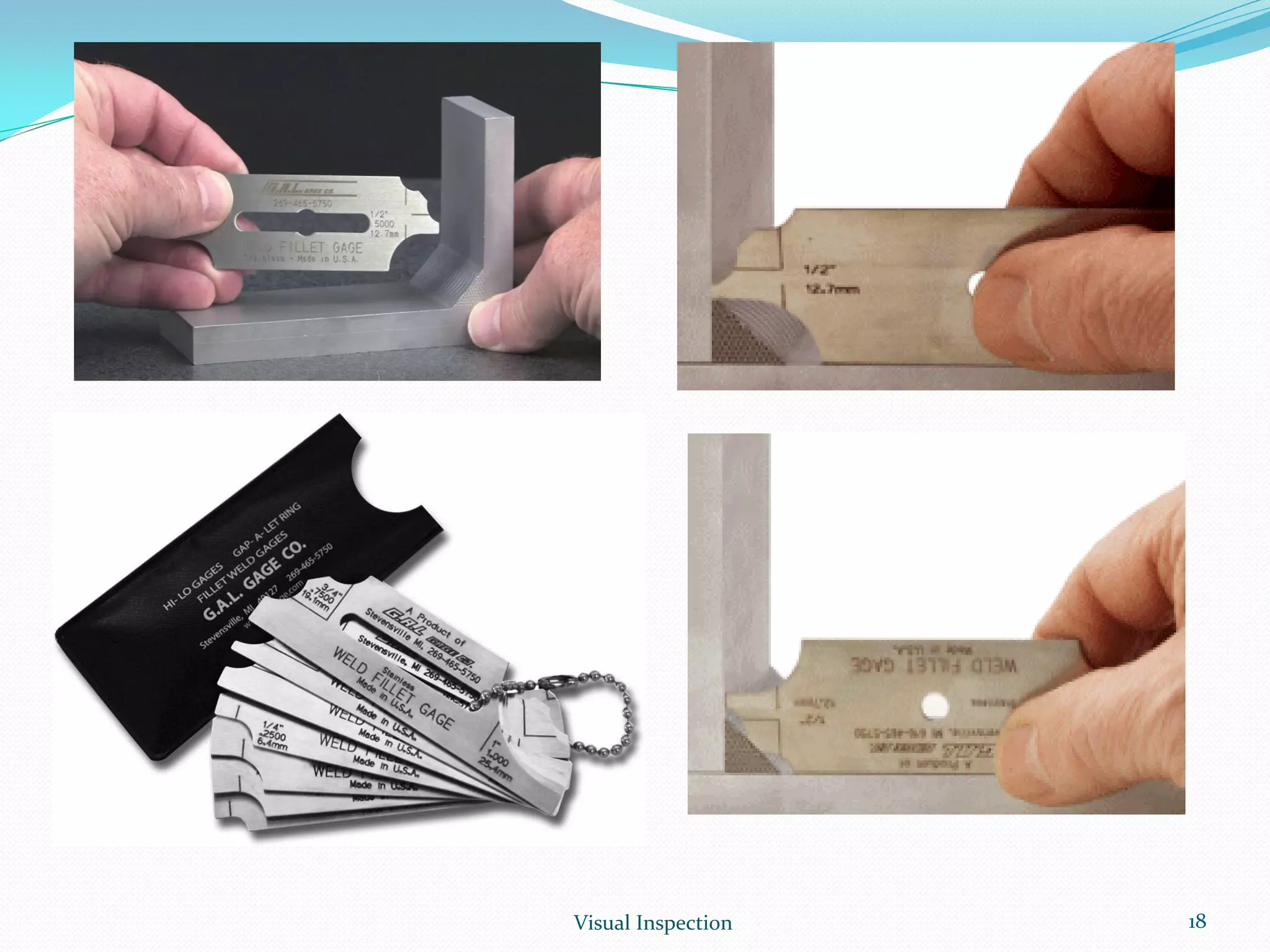

This document provides an overview of non-destructive testing (NDT) methods, focusing on visual inspection. It defines visual inspection as the oldest and most basic NDT method, using only the naked eye to look for flaws. The document distinguishes between unaided visual inspection, using only the eye, and aided visual inspection, which employs optical or mechanical instruments like borescopes, microscopes, calipers and feeler gauges to enhance inspection capabilities. It provides examples of different optical and mechanical aids used to conduct aided visual inspections.