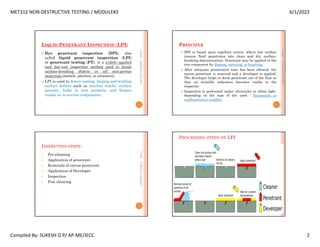

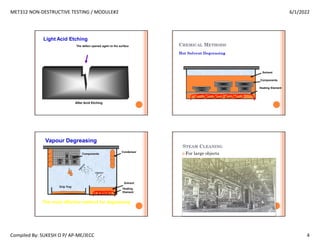

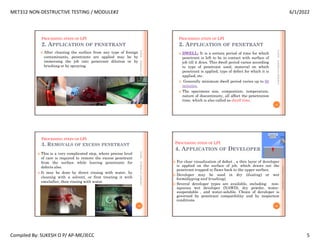

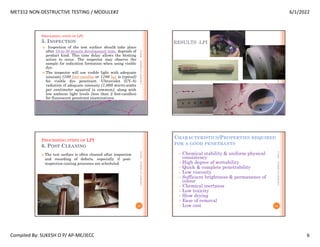

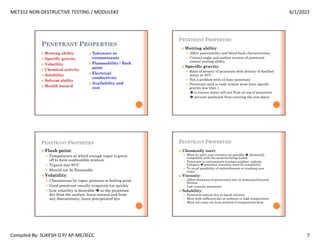

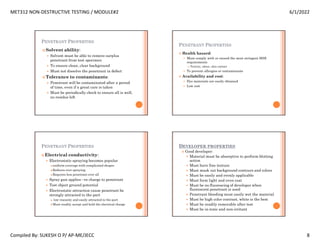

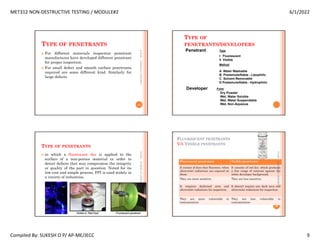

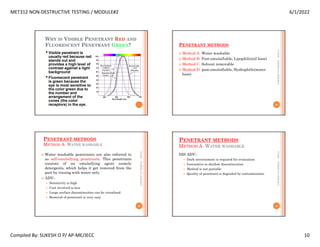

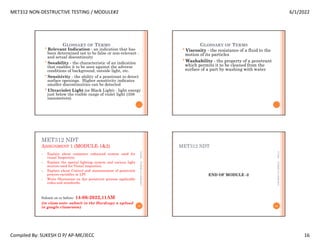

The document discusses liquid penetrant inspection (LPI), a non-destructive testing method used to detect surface-breaking defects. It describes the basic LPI process which involves cleaning, applying a penetrant, removing excess penetrant, applying a developer, and inspecting under UV or white light. The key steps are pre-cleaning, penetrant application, excess penetrant removal, developer application, inspection, and post-cleaning. It also outlines the desired properties of penetrants including wetting ability, viscosity, volatility, and chemical stability. LPI is useful for finding cracks, pores, or leaks in non-porous materials like metals.