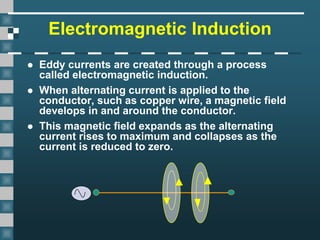

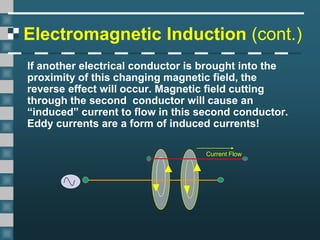

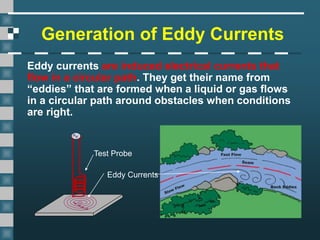

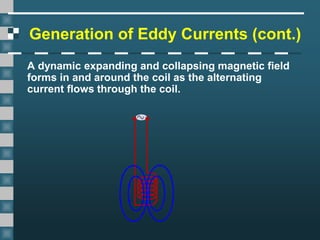

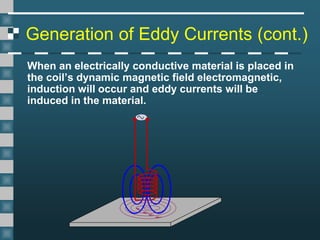

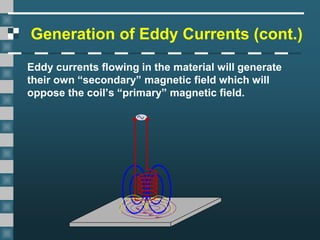

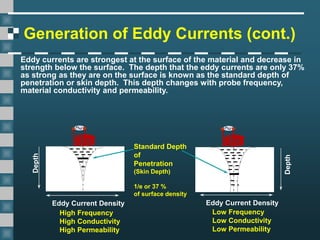

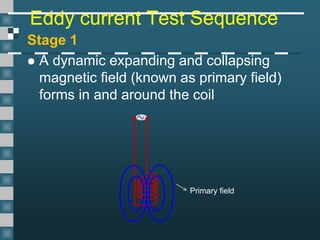

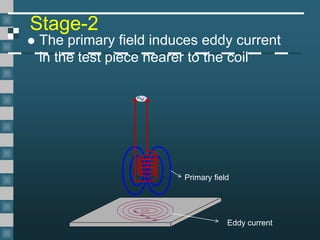

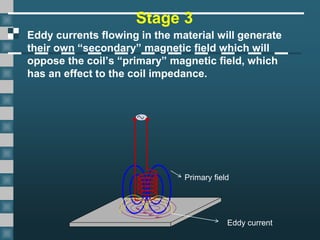

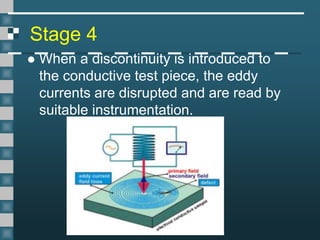

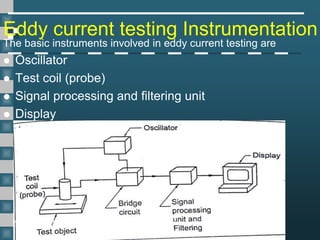

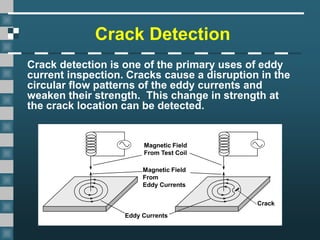

Eddy current testing uses electromagnetic induction to induce eddy currents in a conductive test object. Any flaws or changes in the object will disrupt the eddy current flow and can be detected by sensors. An alternating current is applied to a test coil, generating a changing magnetic field that induces circular eddy currents just below the surface. Disruptions to the eddy currents from flaws are then detected and analyzed to evaluate the test object in less than 3 sentences.