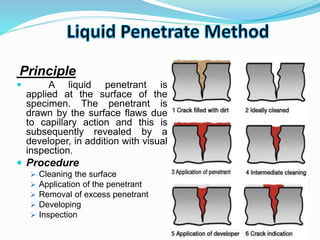

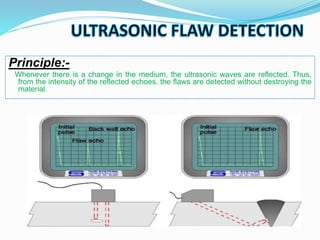

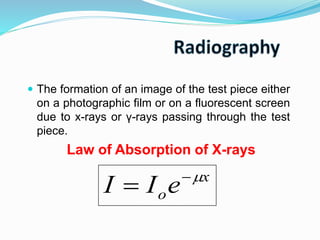

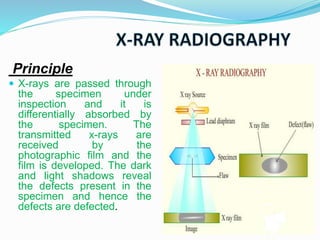

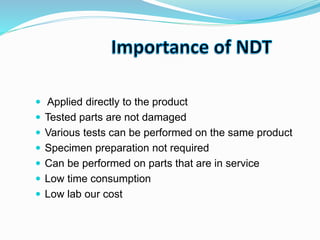

This document discusses non-destructive testing (NDT) methods. It begins by defining NDT as techniques used to evaluate materials without causing damage. It then lists common NDT types like visual inspection, liquid penetrant, ultrasonic, and radiographic testing. For each type, it provides a brief overview of the principles and applications. The document focuses on liquid penetrant testing, describing the procedure and noting it is useful for inspecting parts like aircraft wheels and automotive pistons. It also discusses advantages of NDT like avoiding failures and ensuring safety. In conclusion, it states that NDT can save costs for facilities that implement its methods properly.