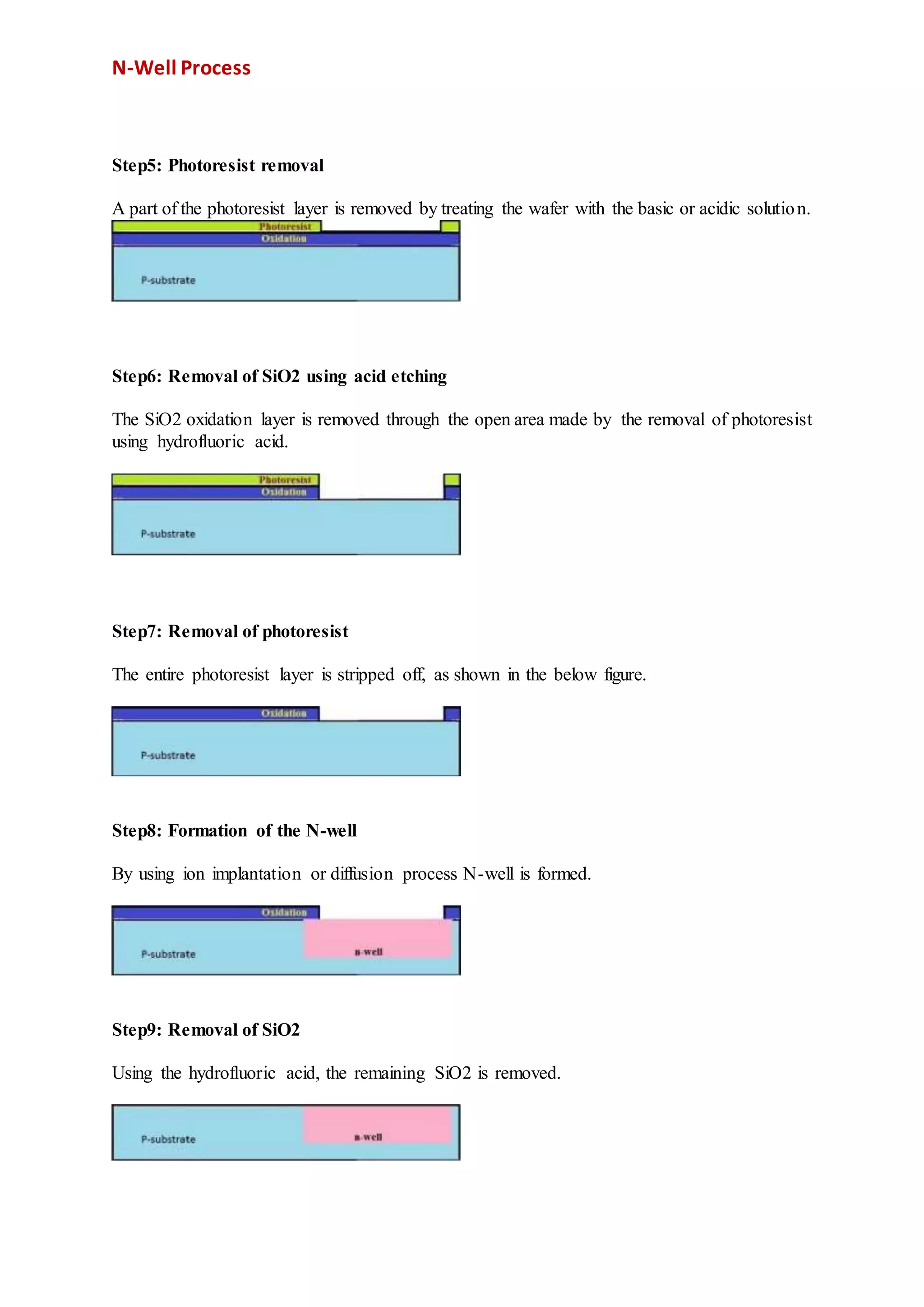

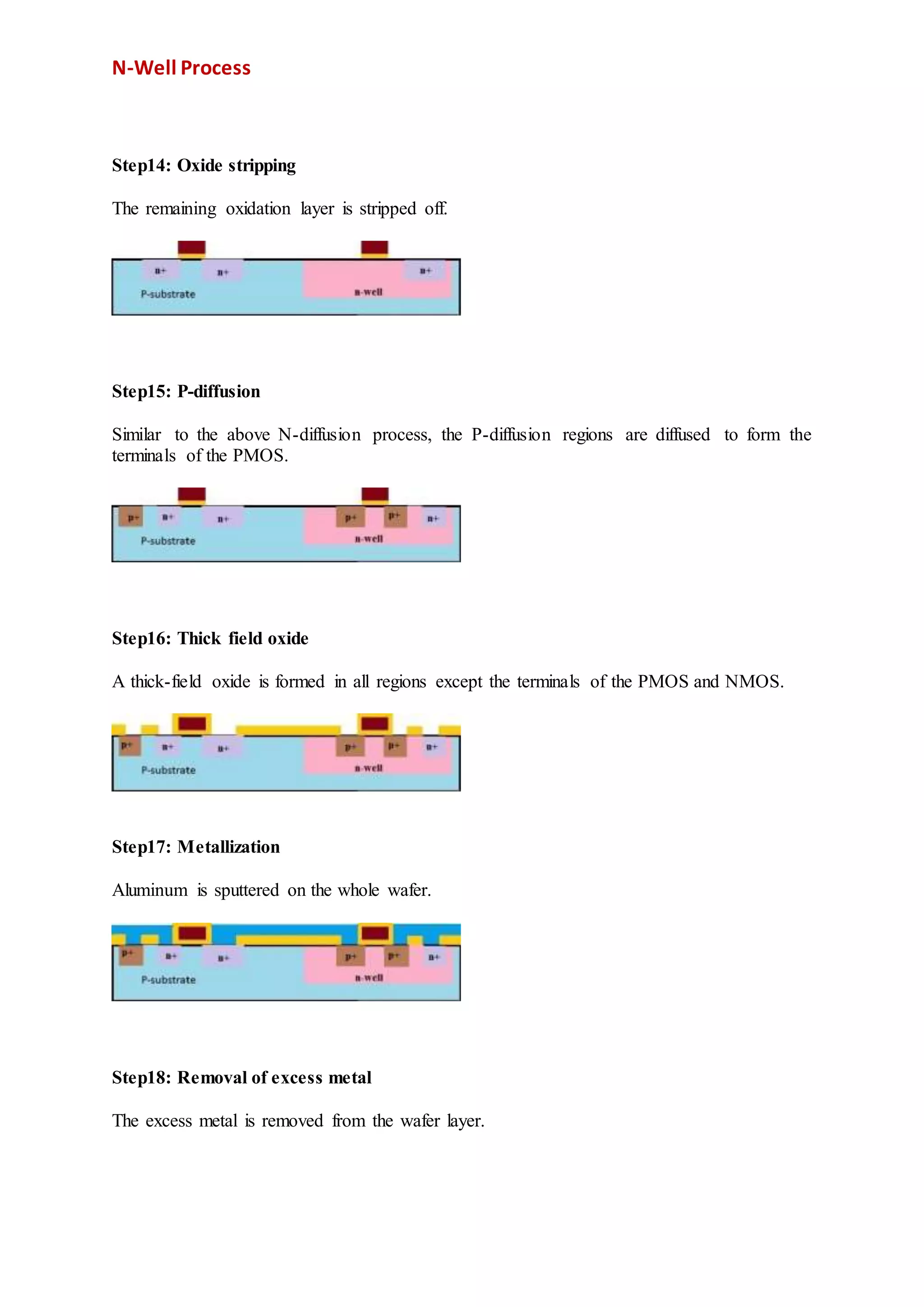

The N-Well process involves 19 steps to fabricate a CMOS device on a P-substrate. It begins with oxidizing the substrate at high temperatures, then depositing and patterning photoresist for ion implantation or diffusion of N-wells. Various layers such as gate oxide and metal are then deposited and patterned before terminals are formed and the device is complete. A similar P-well process exists but uses an N-substrate, while twin tub CMOS allows independent optimization of N and P device characteristics.