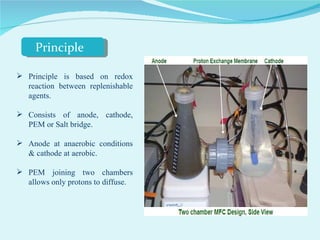

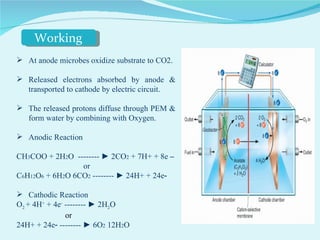

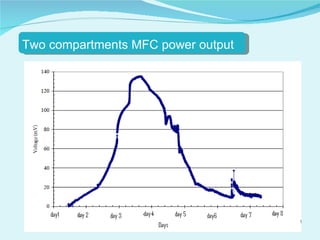

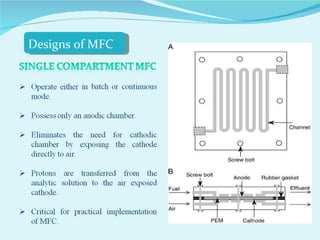

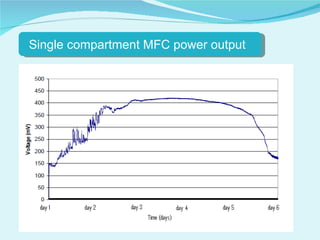

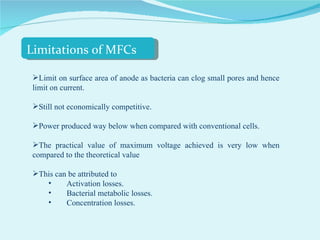

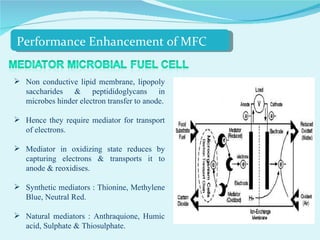

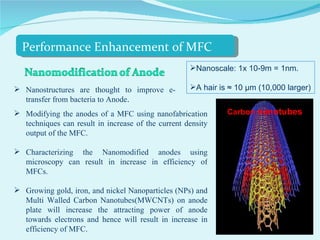

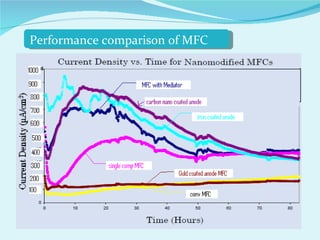

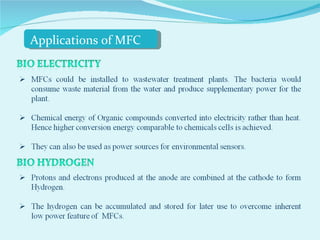

Microbial fuel cells (MFCs) use microorganisms to convert chemical energy from organic matter into electricity. MFCs operate at near-ambient temperatures using microbes that metabolize substrates in wastewater, producing electrons that are harvested to generate electricity. MFCs consist of an anode and cathode separated by a proton exchange membrane, with microbes in the anaerobic anode chamber and oxygen in the aerobic cathode chamber. While MFCs show potential for renewable energy generation and wastewater treatment, challenges remain in improving power output and economic viability at scale.