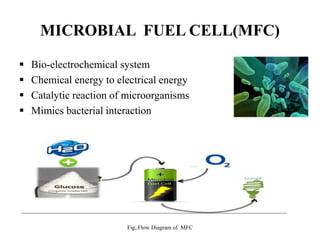

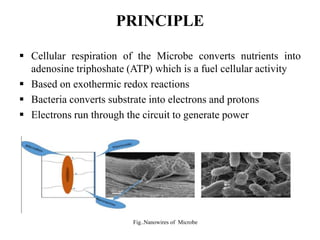

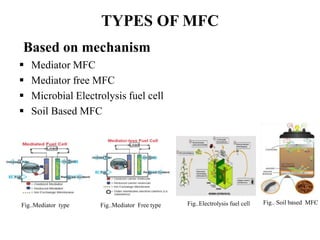

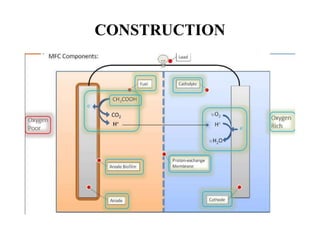

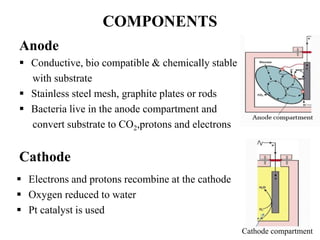

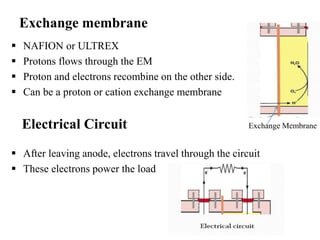

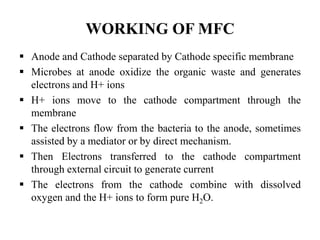

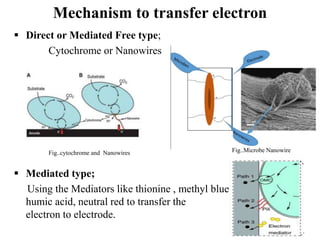

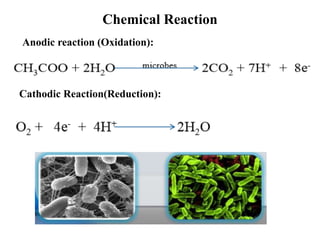

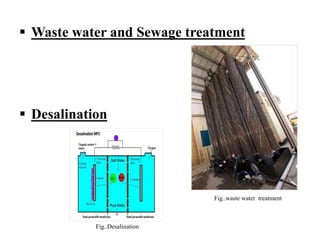

Praveen H M presented on microbial fuel cells (MFCs) which can generate power from waste water. MFCs are bioelectrochemical systems that convert the chemical energy in organic matter into electricity through the catalytic reactions of microorganisms. They consist of an anode and cathode separated by a proton exchange membrane, where bacteria at the anode oxidize the organic waste and generate electrons and protons. The protons flow through the membrane while the electrons flow through an external circuit to the cathode, producing a current that can power devices. MFCs have applications in power generation, wastewater treatment, biosensing and producing biofuels. However, they still face challenges like low power densities and require further