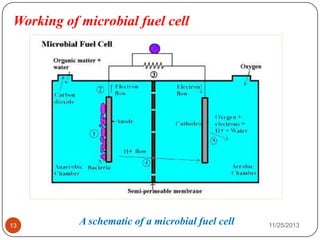

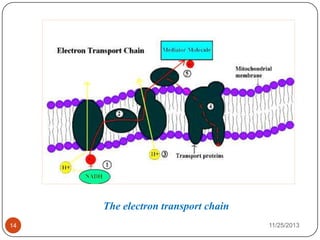

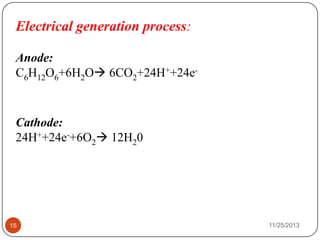

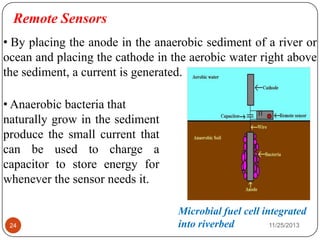

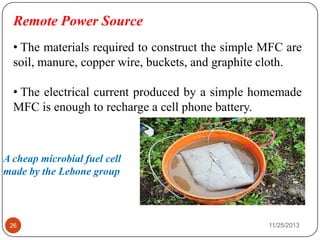

The document discusses microbial fuel cells (MFCs), which use bacteria to generate electricity from organic waste. It begins with an introduction to MFCs and their potential applications. It then provides a brief history of MFCs, describes different types of MFCs and their basic working principle. The document also summarizes several research papers on MFCs and concludes with potential applications of MFCs in wastewater treatment, desalination, hydrogen production, powering remote sensors, and more.

![References

28 11/25/2013

[1] Emmanuel P. Leana and Sandhya Babel, 2011

IEEE First Conference on Clean Energy and Technology CET

“Electricity Generation from Anaerobic Sludge and Cassava

Wastewater Subjected to Pre-treatment Methods Using

Microbial Fuel Cell”.

[2] Vineetha V, Shibu K. Department of Civil Engineering,

College of Engineering, Thiruvananthapuram, Kerala

“Electricity production coupled with Waste water treatment

using microbial fuel cell”](https://image.slidesharecdn.com/specialtopicseminarmicrobialfuelcells-140329093649-phpapp02/85/Special-topic-seminar-microbial-fuel-cells-28-320.jpg)

![29 11/25/2013

[3] Seyed Kamran Foad Marashi, Hamid-Reza Kariminia

Department of Chemical and Petroleum Engineering

Sharif University of Technology Tehran, Iran

“Electricity Generation from Petrochemical Wastewater

Using a Membrane-Less Single Chamber” Microbial Fuel

Cell

[4] Hongwei Gao, Andrew Meehan, and Zbigniew

Lewandowski Montana State University, Bozeman, USA

“New Microbial Fuel Cell Power System for

Efficiency Improvement”](https://image.slidesharecdn.com/specialtopicseminarmicrobialfuelcells-140329093649-phpapp02/85/Special-topic-seminar-microbial-fuel-cells-29-320.jpg)