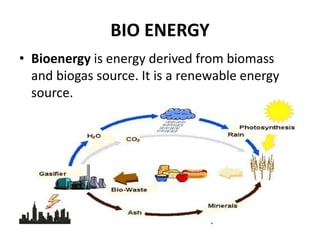

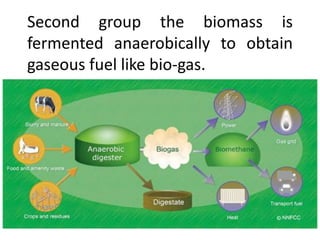

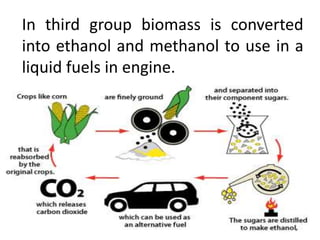

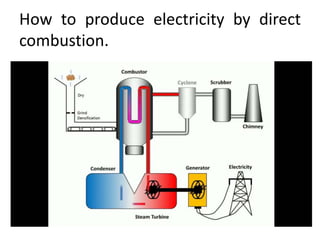

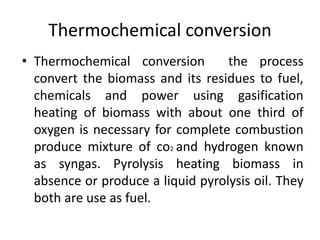

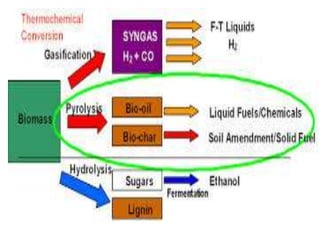

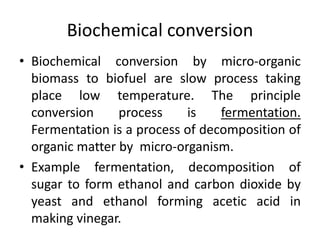

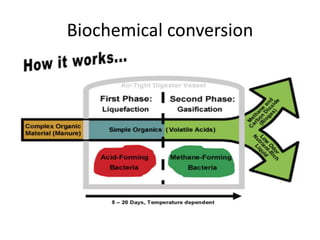

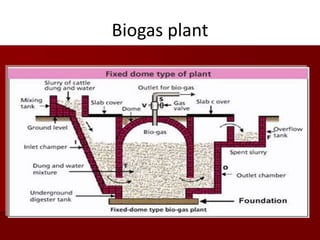

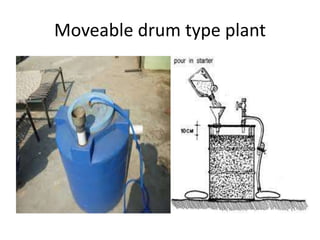

This document provides information about bioenergy and different types of biogas plants. It begins with definitions of bioenergy and biomass, describing biomass as a renewable energy source derived from organic matter. It then discusses three types of biomass and different processes for converting biomass into energy: direct combustion, thermochemical conversion (like gasification and pyrolysis), and biochemical conversion (like fermentation). The document also summarizes advantages and disadvantages of biomass energy. It describes two main types of biogas plants - dome type and movable drum type - and compares their characteristics, such as construction, operation, costs and maintenance.