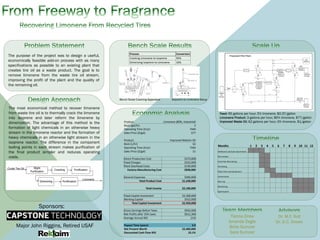

The project aims to design a process to remove limonene from waste tire oil at an existing plant, improving profits and oil quality. The most economical method is to thermally crack limonene into isoprene and then reform limonene by dimerizing isoprene. This creates lighter and heavier streams for simpler purification, reducing costs. The process yields limonene and improved waste oil, with estimated costs, profits, and investment metrics showing strong returns over a 2 year payback period.