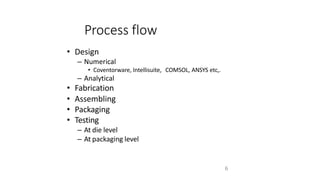

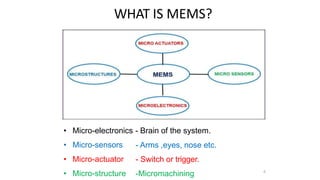

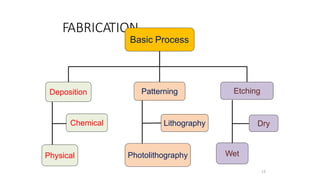

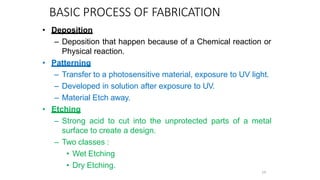

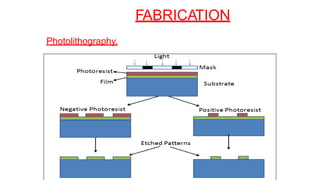

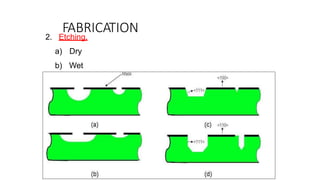

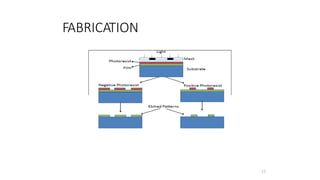

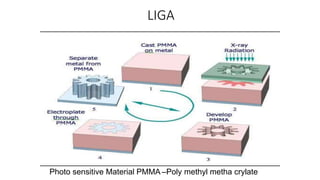

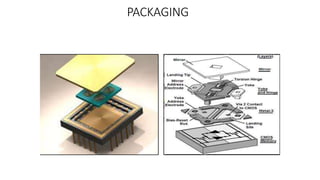

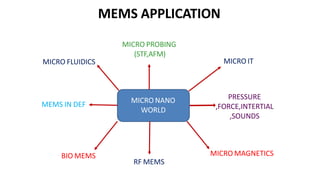

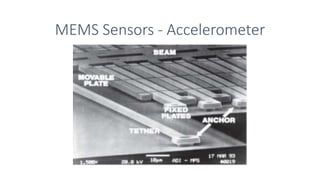

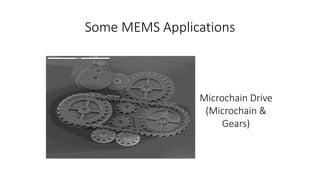

Micro-electro-mechanical systems (MEMS) are miniature devices that combine electrical and mechanical components. MEMS components range in size from 1-100 micrometers and are fabricated using microfabrication techniques. MEMS devices can sense and control the physical world on small scales and have applications in areas like sensors, actuators, and biomedical devices. The document discusses MEMS fabrication techniques including deposition, patterning, etching, and packaging and provides examples of common MEMS devices and applications.