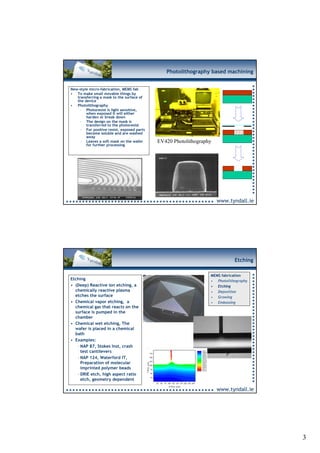

The document discusses the history and fabrication processes of Micro-Electro-Mechanical Systems (MEMS) at the Tyndall National Institute, highlighting techniques like photolithography, etching, and deposition. It details the evolution of small mechanical devices from the 15th century to modern MEMS applications in various industries, including automotive and biomedical fields. The presentation also outlines different fabrication methods, such as bonding and embossing, to create small movable components.