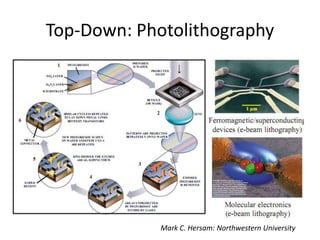

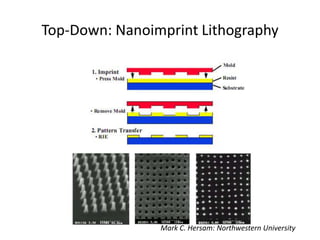

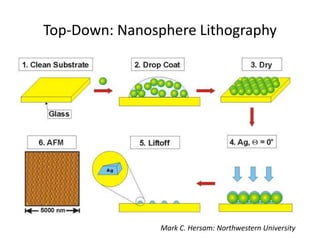

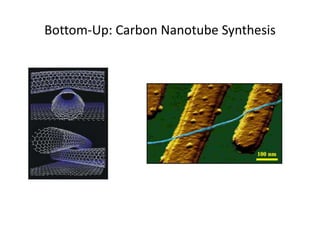

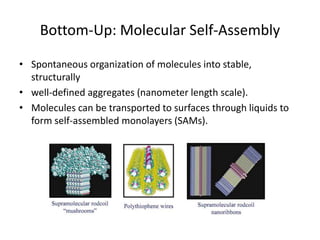

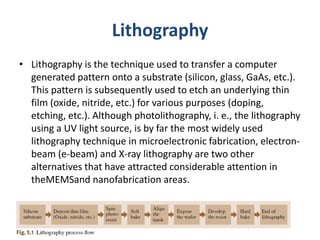

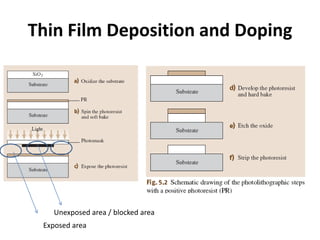

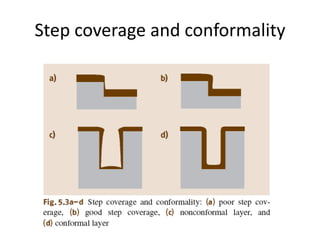

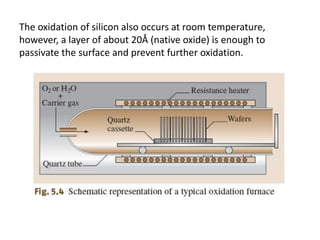

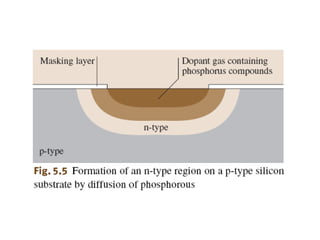

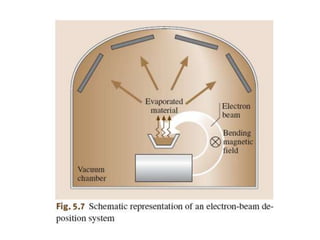

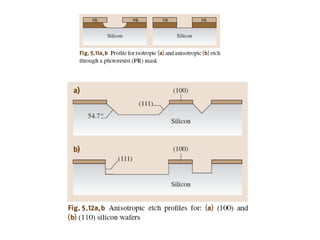

This document provides an overview of microfabrication and nanofabrication techniques. It discusses both top-down approaches like photolithography, nanoimprint lithography, and nanosphere lithography as well as bottom-up techniques such as carbon nanotube synthesis and molecular self-assembly. The document also covers common microfabrication processes like thin film deposition, doping, oxidation, etching, and lithography. It provides details on lithography methods, thin film deposition techniques like CVD and PVD, and etching approaches including wet and dry etching.