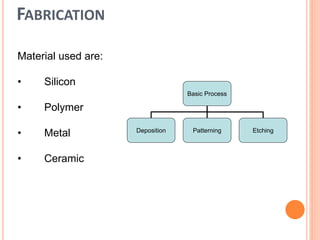

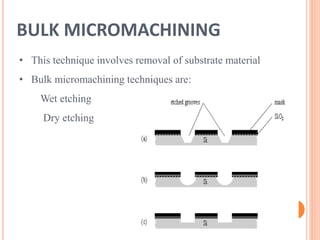

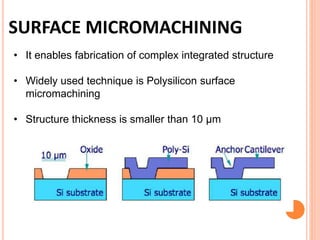

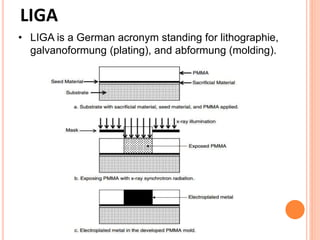

This document provides an overview of a presentation on MEMS (Micro-Electro-Mechanical Systems) technology. It defines MEMS as tiny integrated devices that can sense, control, and actuate. The document outlines the presentation sections on MEMS sensors, fabrication methods like bulk micromachining and surface micromachining, packaging, advantages like small size and low power consumption, and applications in medical, industrial, and communication fields. It concludes that MEMS is an effective technique for producing low-cost, high-quality sensors and will help improve lives by enabling real-time data collection and a better understanding of the physical world.

![REFERENCE

1. Microsensors , Muller, R.S., Howe, R.T., Senturia , S.D.,

Smith, R.L., and White, R.M. [Eds.], IEEE Press, New York,

NY, 1991.

2. Micromechanics and MEMS: Classic and Seminal Paper

to 1990, Trimmer, W.S., IEEE Press, New York, NY, 1997.

3. Journal of Micro-electro-mechanical-Systems

(http://www.ieee.org/pub_preview/mems_toc.html)

4. Journal of Micromechanics and Microengineering

(http://www.iop.org/Journals/jm)](https://image.slidesharecdn.com/memstecnology-150927054758-lva1-app6892/85/Mems-tecnology-17-320.jpg)