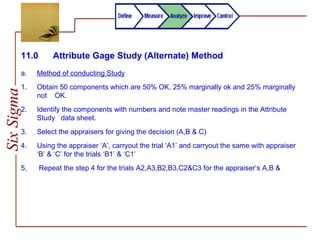

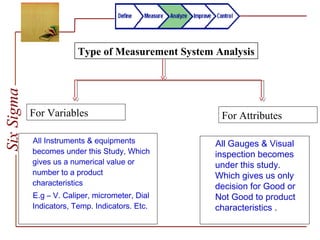

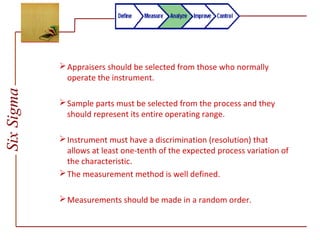

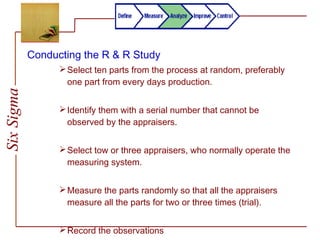

1. A gauge R&R study involves measuring sample parts with different appraisers using the same gauge to determine measurement system variability.

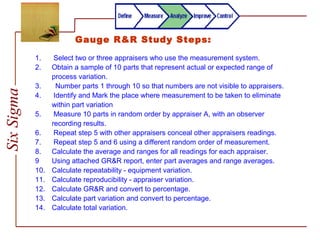

2. Key steps include selecting appraisers, obtaining a representative sample of 10 parts, measuring the parts in random order over multiple trials while recording the results, and calculating various variations to determine if the measurement system is acceptable.

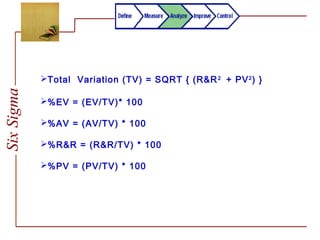

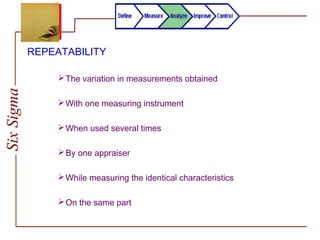

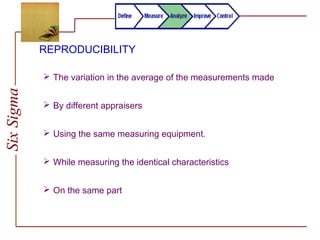

3. Acceptance criteria for gauge R&R is less than 10% for good systems and 10-30% for systems that may need evaluation depending on the application. The study quantifies repeatability, reproducibility and overall gauge R&R variation.

![SixSigma

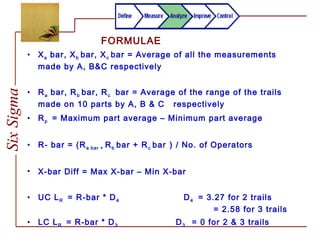

Homogenize the data for Range

Calculate R-bar, X-bar Diff and Rp only after

homogenizing

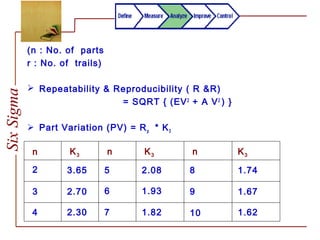

Equipment Variation (EV) = R-bar * K1

(K1 = 4.56 for 2 trails

= 3.05 for 3 trails)

Appraiser Variation (AV)

= SQRT { (X-bar Diff * K2 )2

– [ EV2

/ (nr)]}

(K2 = 3.65 for 2 operators

= 2.70 for 3 operators)](https://image.slidesharecdn.com/measurementsystemanalysis-171023144849/85/Measurement-system-analysis-19-320.jpg)